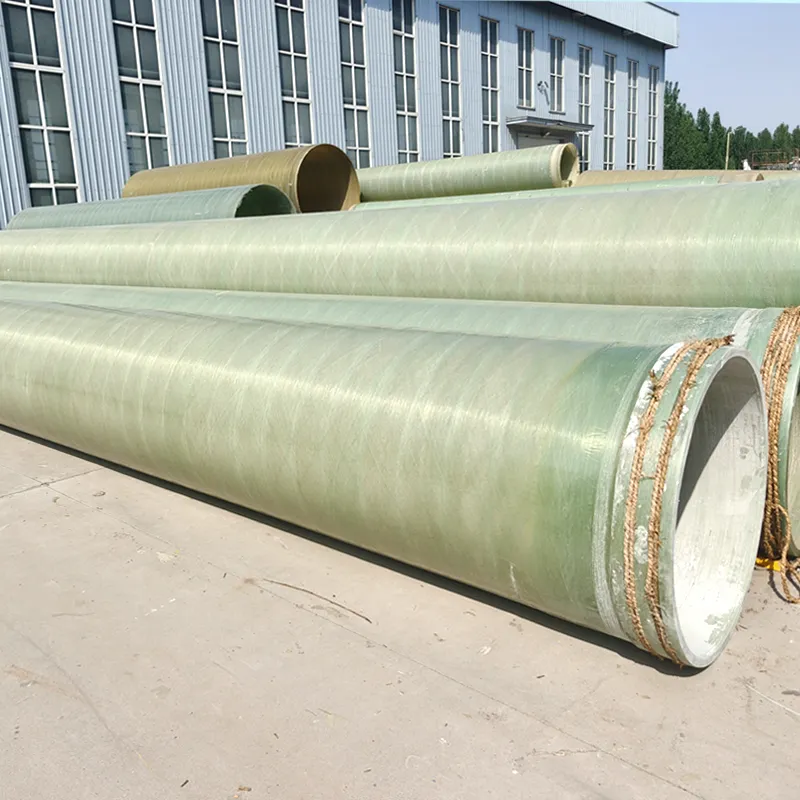

The RPM pipe is composed of inner layer, wound layer, resin-mortar layer and exterior corrosion-resistant layer, its density is 1.7~2.1, equals one fifth of steel pipe, one fourth of cast steel pipe and three fourth of pretensioned concrete pipe. As the filament wound reinforced structure exists at the two sides of resin-mortar layer, and its fiber contedt is 70%, so it can meet the strength requirement of the pipeline. Else, as the resin-mortar layer is between the middle areas--lower stress area, so it has increased the stifness meantine no any decrement to the strength of the pipe.

The corrosion-resistant property of RPM pipe is mainly relied on the inner resin, and be selected in accordance with the condition of the media. lt is adopted the reinforced rich resin laver by fiberglass, the resin content is 80%, it can ensure that the RPM pipe prevent corrosion and leakage.

The inner surface of the RPM pipe is very smooth; the roughness coefficient is very small. Not only the inner surface of new produced pipe is very smooth, but also it is same smooth as the beginning after has been used many years, and no seaweed and other aquatic derivative be adhered. The water conservancy factor(C) can be kept within 140 and 150 during a long period.

After the relative testing, its friction factor(f) is 0.0009 15, it is smaller than the (f=0.00232) and the steel pipe (SP)(f=0.00 179).

It can decrease the pressure head loss obviously; capacity above 20%. So when the conveying the increase conveying capacity 1S same, can adopt the RPM pipe with lower diameter, can save the investment of the project.

|

Diameter |

DN15-4000mm |

|

Length |

6m/12m per piece |

|

Pressure |

0.1MPa, 0.6MPa, 1.0MPa, 1.6MPa |

|

Stiffness |

2500Pa, 5000Pa, 10000Pa |

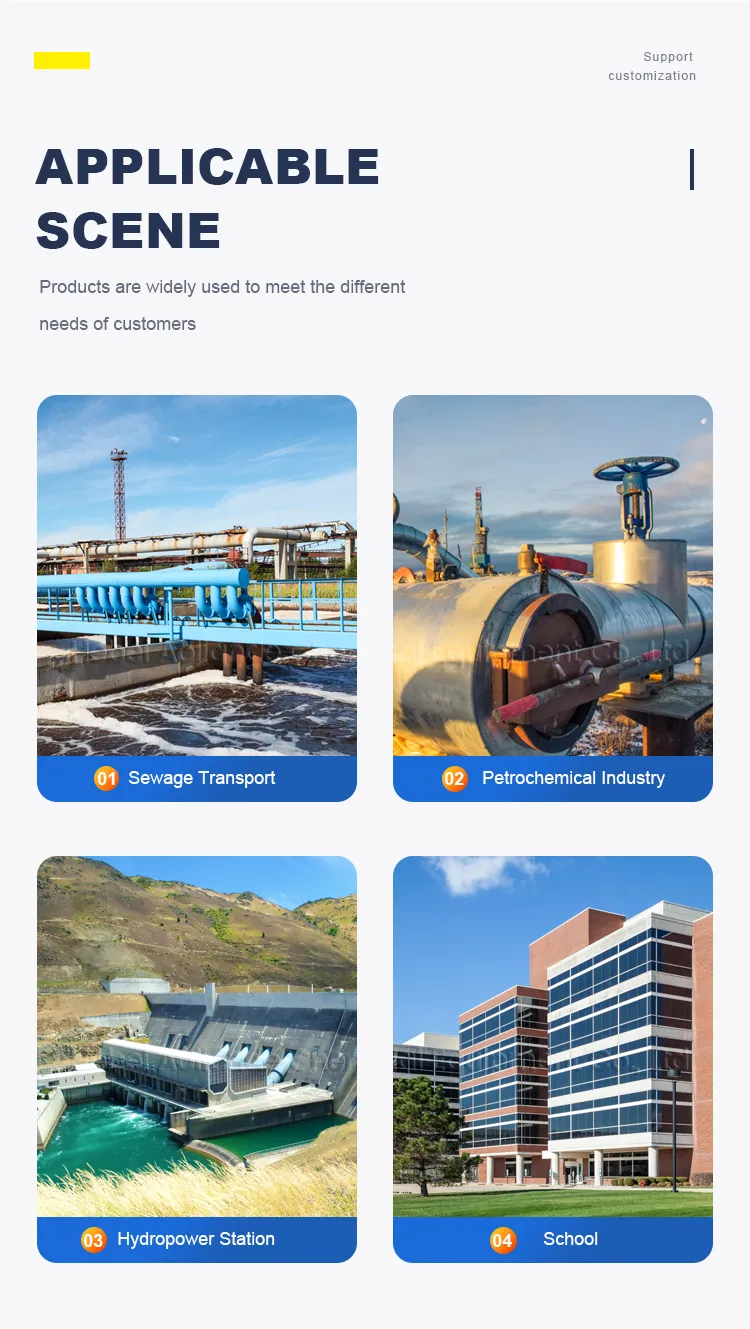

FRP pipes are used in petroleum, chemical and drainage industries.

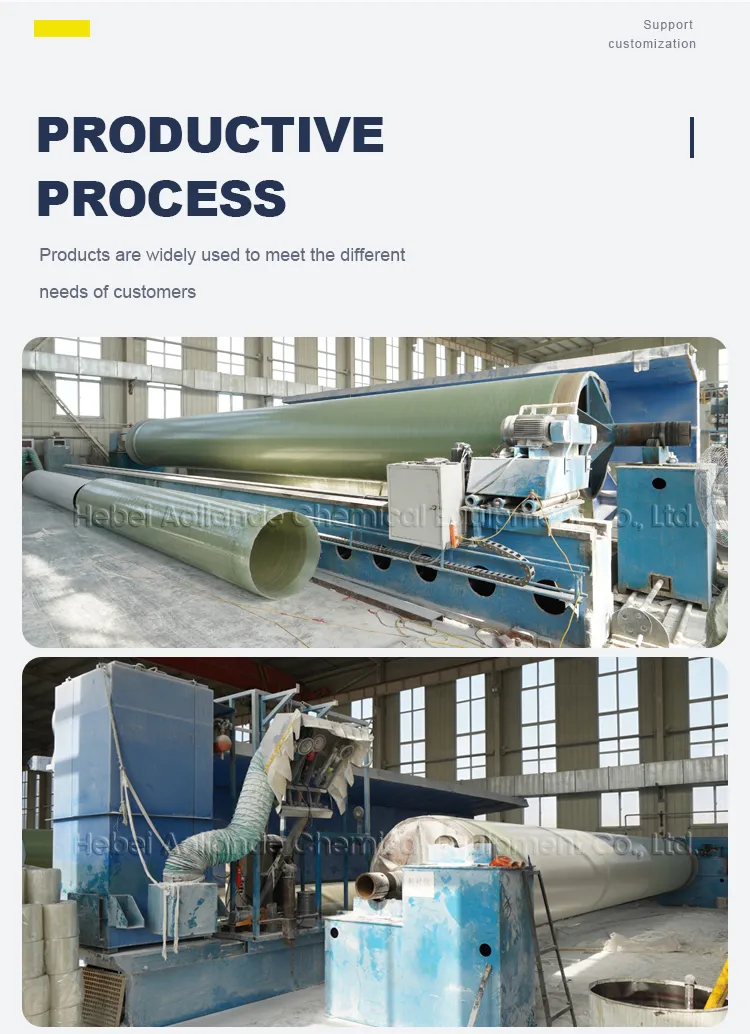

The length-fixed winding process is controlled by computer. Manufacture the liner on the mandrel as the same process of fiber glass winding pipe, then after the resin became hardened, make the structure layer by winding according to the designed linearity and thickness, and add the mixture of mortar and resin into the structure layer, finally, wind the outer protection layer.

The pipe is consisted of inner liner, interface, structural layer, and outer surface layer.

Inner liner corrosive resistance layer, Surfaces exposed to the chemical environment shall be resin-rich and reinforced with a 10 or 20 mil thick chemical surfacing mat (E- glass).

Interface layer is leakage proof layer, it be reinforced by minimum of three layers of 1.5 oz chopped strand mat.

Structural layer will be reinforced by continuous strand fiberglass roving and shall maintain a resin content of 20-40%. It is reinforcement for the inner lining layer and interface, resisting the foreign load to the pipe body and ensures the strength and stiffness of the pipe body.

The exterior surface shall consist of a chopped strand glass over which a resin-rich coating shall be applied.

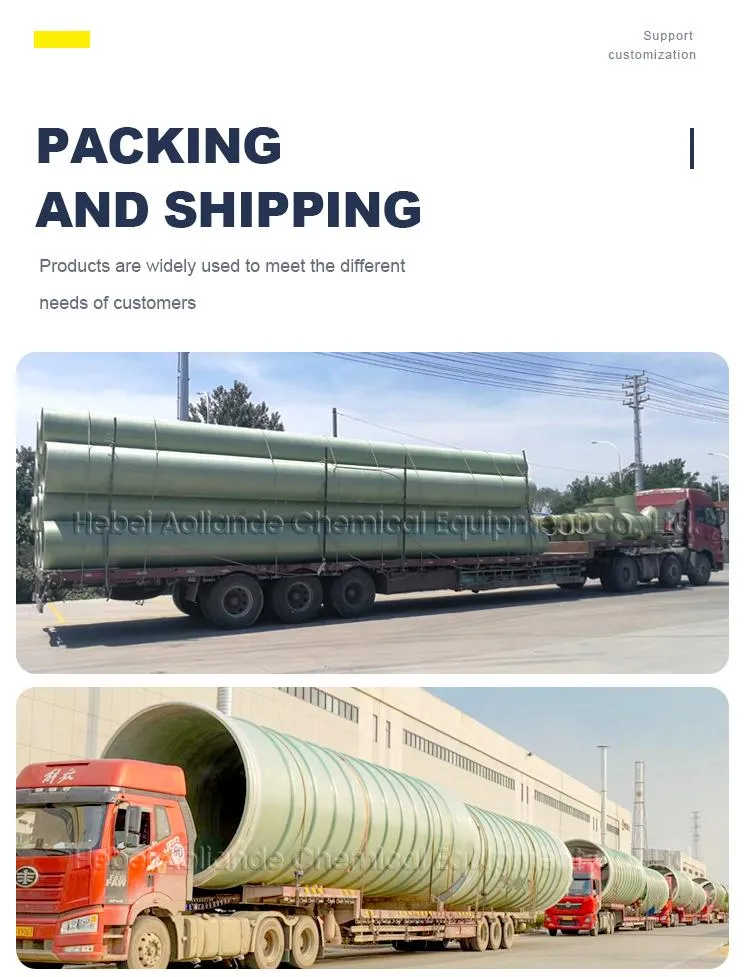

Hebei Aoliande chemical Equipment co., Ltd, is a professional company selling FRP pipes, FRP storage tanks, FRP molding products and FRP production machinery, the company through continuous development and introduction of professional and technology, relying on advanced technology, exquisite technology, reliable quality and perfect service, passed ISO9001, ISO14001 management system certification, now we have more than 50 employees, the annual sales of FRP series products reached 5,000,000 us dollars. Products have been sold all over the world, the United states, Brazil, Japan, Germany.India, Malaysia, Egypt, etc., won the support and trust of new and old customers.

"The Aoliande FRP Pipes are highly durable, and they’ve performed excellently in tough conditions."

"These FRP/GRP Pipes are perfect for our industrial applications, with no leaks or problems."

"Reliable, strong, and corrosion-resistant—our FRP/GRP pipes are the best choice for us."