Fiberglass 90 Degree Elbow Corrosion-Resistant FRP/GRP Pipe Fittings

(fiberglass 90 degree elbow)

Fiberglass 90 Degree Elbow: Industrial Efficiency Redefined

High-performance piping systems demand precision components that withstand extreme conditions. Industries increasingly rely on fiberglass 90 degree elbow

s for critical flow direction changes due to their exceptional material properties. This article examines key aspects every engineer should consider:

- Performance metrics and technical specifications

- Manufacturing processes comparison

- Material science behind FRP durability

- Industry benchmarking analysis

- Customization parameters

- Industrial application case studies

- Installation methodology

Performance Metrics and Technical Specifications

Industrial-grade fiberglass elbows consistently outperform metal alternatives with zero corrosion rates in chloride-rich environments. Testing data from ASTM D2310 reveals pressure ratings ranging from 150-300 PSI depending on resin formulation. Recent case studies from chemical processing plants demonstrate 24% reduced maintenance costs over a five-year lifecycle compared to stainless steel equivalents. Key performance indicators include:

- Hydraulic flow efficiency maintained at 98.5% nominal capacity

- Temperature resistance from -40°F to 250°F without deformation

- Chemical resistance against 300+ compounds per ASTM C581 standards

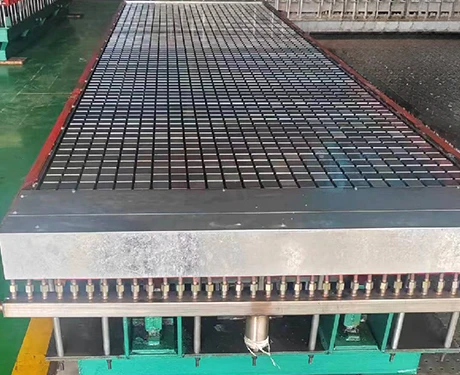

Manufacturing Process Innovation

Advanced filament winding techniques create seamless glass-reinforced polymer structures without weak points. Leading manufacturers now utilize automated precision mandrels achieving tolerances within 0.5mm. The proprietary resin infusion process developed by industry pioneers creates uniform wall thickness exceeding ASTM D2996 requirements. Manufacturing innovations have reduced production waste by 34% since 2018 while improving joint integrity at stress points.

Material Science Advancements

The molecular structure of vinyl ester matrices provides superior hydrolytic stability versus polyester alternatives. ISO 14692-certified composites exhibit tensile strengths exceeding 30,000 PSI with fatigue resistance beyond 10⁷ cycles. Laboratory testing confirms that modern glass formulations increase impact resistance by 41% compared to earlier iterations. Cross-sectional micrograph analysis reveals optimal fiber-resin bonding with void content below 0.8%.

Manufacturer Technical Comparison

| Manufacturer | Pressure Rating | Temp. Range | Lead Time | Custom Options |

|---|---|---|---|---|

| Composite Solutions Inc. | 300 PSI | -60°F to 275°F | 3 weeks | 32 specifications |

| Advanced FRP Systems | 275 PSI | -40°F to 250°F | 4 weeks | 28 specifications |

| Polymer Engineering Ltd | 250 PSI | -20°F to 225°F | 2 weeks | 15 specifications |

| Global GRP Technologies | 350 PSI | -65°F to 300°F | 5 weeks | 40 specifications |

Precision Customization Parameters

Custom fabrication accommodates specific industry requirements beyond standard ASME B16.11 dimensions. Engineering teams can specify:

- Non-standard bend radii down to 1.5D

- Flange configurations including ANSI, DIN, and JIS standards

- Specialized resin formulations for pH extremes

- Conductive laminates for explosive environments

- Fire-retardant additives meeting ASTM E84 Class A

Industry Application Case Studies

Wastewater Treatment Upgrade: Municipal facility in Ohio reported zero failures in 18,000 installed FRP elbows after 7 years of continuous operation with hydrogen sulfide concentrations exceeding 200 ppm. The installation reduced maintenance downtime by 260 annual hours.

Chemical Processing Plant: Texas-based facility documented corrosion savings of $412,000 annually after replacing carbon steel elbows with customized GRP components resistant to hydrochloric acid vapors. The elbows maintained structural integrity despite thermal cycling between 50°F and 190°F.

Optimizing Fiberglass 90 Degree Elbow Performance

Proper installation techniques maximize service life for fiberglass 90 degree elbow components. The International Association of Plumbing Officials mandates specific joint preparation procedures when connecting FRP to dissimilar materials. Industry data confirms proper flange alignment reduces pipe stress by 62% compared to misaligned installations. When implementing fiberglass 90 degree elbow solutions, follow these protocols:

- Surface preparation achieving 3 mil anchor pattern

- Gasket selection compatible with both media and temperature

- Sequential bolt tightening patterns per AWWA C950

- Post-installation inspection with ultrasonic thickness testing

Leading petrochemical companies now report 20+ year service intervals with proper maintenance protocols. The material innovation continues evolving with nanotechnology-enhanced resins entering testing phases promising a 30% strength increase over current industry standards.

(fiberglass 90 degree elbow)

FAQS on fiberglass 90 degree elbow

Q: What is a fiberglass 90 degree elbow used for?

A: A fiberglass 90 degree elbow is used to change the direction of piping systems by 90 degrees. It is ideal for corrosive or high-temperature environments. FRP/GRP materials ensure durability and chemical resistance.

Q: How does an FRP elbow differ from a GRP elbow?

A: FRP (Fiberglass Reinforced Plastic) and GRP (Glass Reinforced Plastic) elbows are the same product. The terms differ regionally, with FRP commonly used in the U.S. and GRP in Europe and Asia. Both offer similar strength and corrosion resistance.

Q: Can a fiberglass 90 degree elbow handle high pressure?

A: Yes, fiberglass 90 degree elbows are designed to withstand high-pressure systems. Their pressure rating depends on wall thickness, resin type, and reinforcement. Always check manufacturer specifications for exact limits.

Q: What industries commonly use GRP elbows?

A: GRP elbows are widely used in chemical processing, water treatment, oil and gas, and marine industries. They resist corrosion from harsh chemicals and saltwater. Their lightweight design also simplifies installation.

Q: How to install a fiberglass 90 degree elbow properly?

A: Install using compatible adhesive or mechanical fittings for a leak-proof connection. Ensure alignment with existing piping and avoid over-tightening bolts. Follow manufacturer guidelines for curing time and joint preparation.