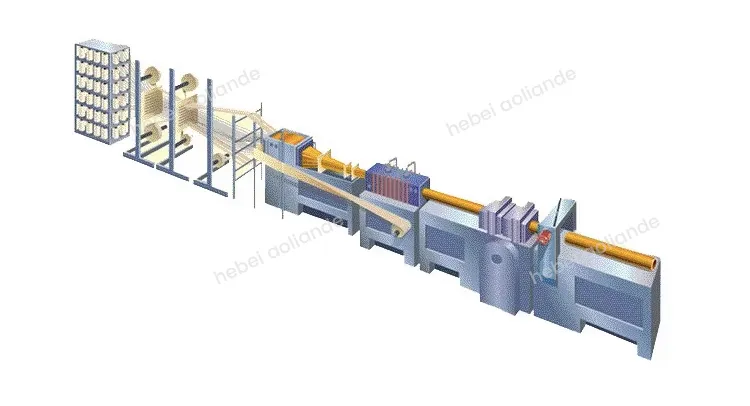

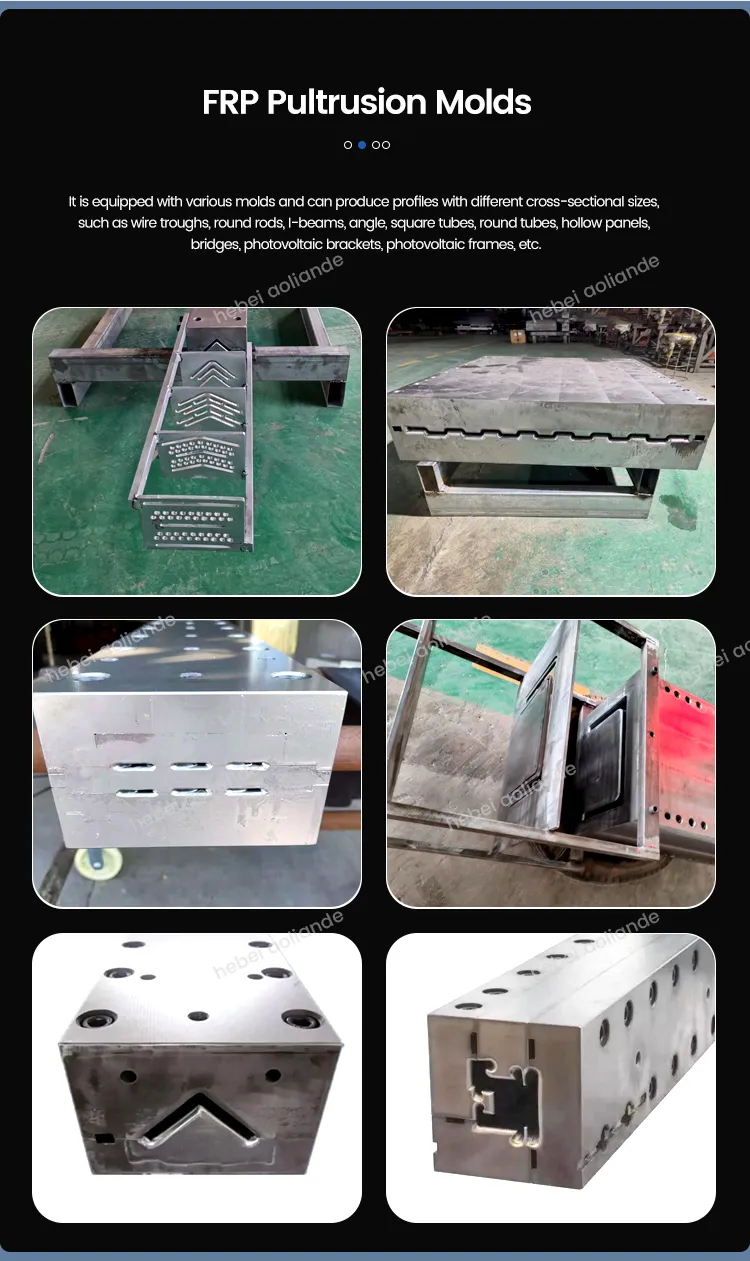

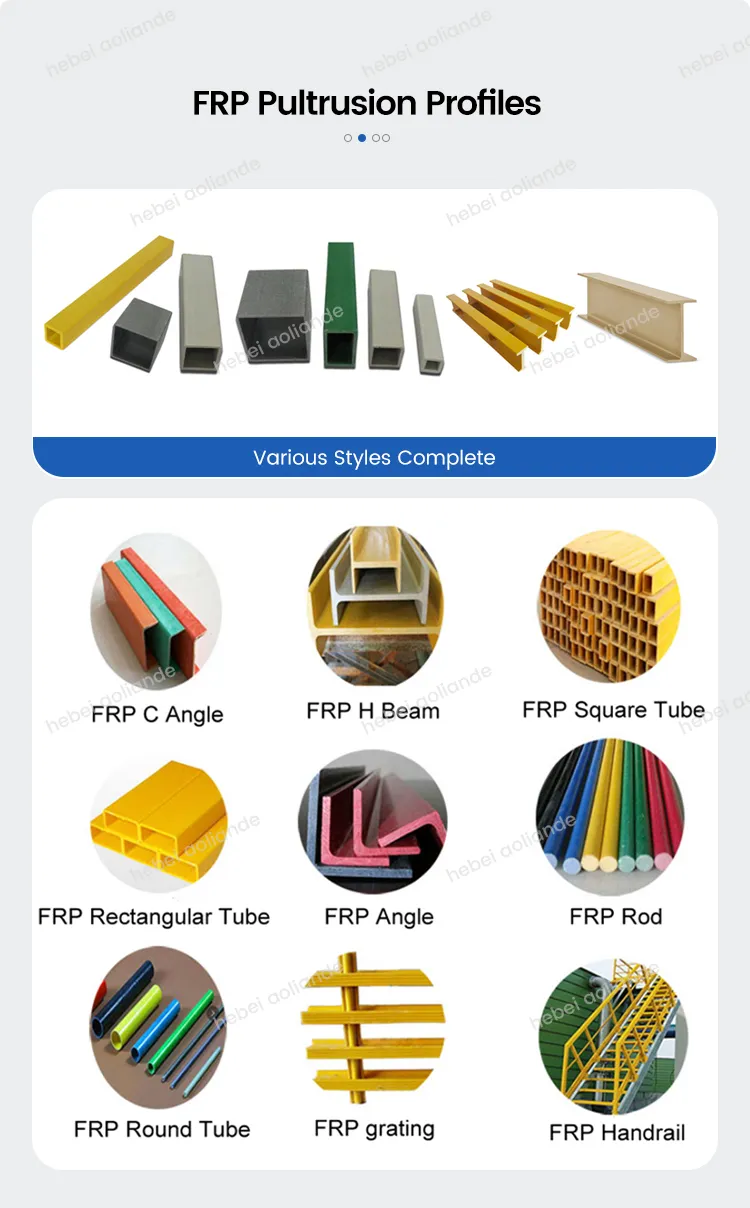

The FRP pultrusion production line is PLC-controlled with an LCD display and integrates hydraulic reciprocating traction and pneumatic fixed-length cutting. It includes a creel, dipping tank, mold table, tractor, cutting saw, and product support rack. With various molds, it can produce profiles like wire troughs, I-beams, square tubes, and photovoltaic frames. The FRP pultrusion winding production line combines pultrusion and winding processes, enhancing both longitudinal and transverse strength. It improves pipe production efficiency and significantly boosts pressure resistance through uniform winding of reinforcing materials like glass fiber mat and fiberglass cloth.

FRP pultrusion machine main technical parameters:

Total power of the unit: 380v/50hz 25kw (including mold heating)

Overall dimensions:26m(length)x2m(width)x 2m

|

Items/Type |

ZLRCYZ -3 |

ZLRCYZ -6 |

ZLRCYZ -10 |

ZLRCYZ -12 |

ZLRCYZ -15 |

ZLRCYZ -25 |

|

Pulling Force(Tons) |

3 |

6 |

10 |

12 |

15 |

25 |

|

Clamping Force(Tons) |

Manual |

6 |

10 |

12 |

15 |

25 |

|

Pulling Speed(m/min) |

0.1-1.4 |

0.1-1.5 |

0.1-1.5 |

0.1-1.5 |

0.1-1.5 |

0.1-1.2 |

|

Envelop(W*H)m |

0.25*0.07 |

0.6*0.15 |

0.6*0.25 |

0.7*0.3 |

0.8*0.35 |

1.0*0.5 |

|

Motor Cahacity(kw) |

2.2 |

2.3 |

2.4 |

2.55 |

2.75 |

2.75 |

|

Heating capacity(kw) |

9.6 |

9.6 |

9.6 |

12 |

14.4 |

18 |

|

Heating board size(L*W)m |

0.85*0.4 |

0.85*0.6 |

0.85*0.6 |

0.85*0.6 |

0.85*0.7 |

0.9*0.8 |

|

Dimensions(L*W)m |

6.2*1.2 |

8.3*0.85 |

8.4*0.9 |

10*1.0 |

11*1.1 |

11*1.3 |

|

Total weight(Tons) |

1.2 |

3 |

3.5 |

4 |

4.5 |

6 |

|

Transmit Type |

Mechnic ai drive |

Hydraulic |

||||

FRP Pultrusion Machine Features:

1. Temperature control adopts high-precision, dual-display instruments

2. Digital display of traction speed

3. The hydraulic cylinder seals are imported, and the hydraulic system uses a low-noise, energy-saving variable pump.

4. With automatic alarm for oil temperature and oil level faults.

5. The hydraulic traction device has a variety of working modes to choose from, and the traction speed can be adjusted steplessly.

6. Using gear and rack for transverse cutting, pneumatic pressing, pneumatic tracking, and the cutting blade is toothlesssaw blade.

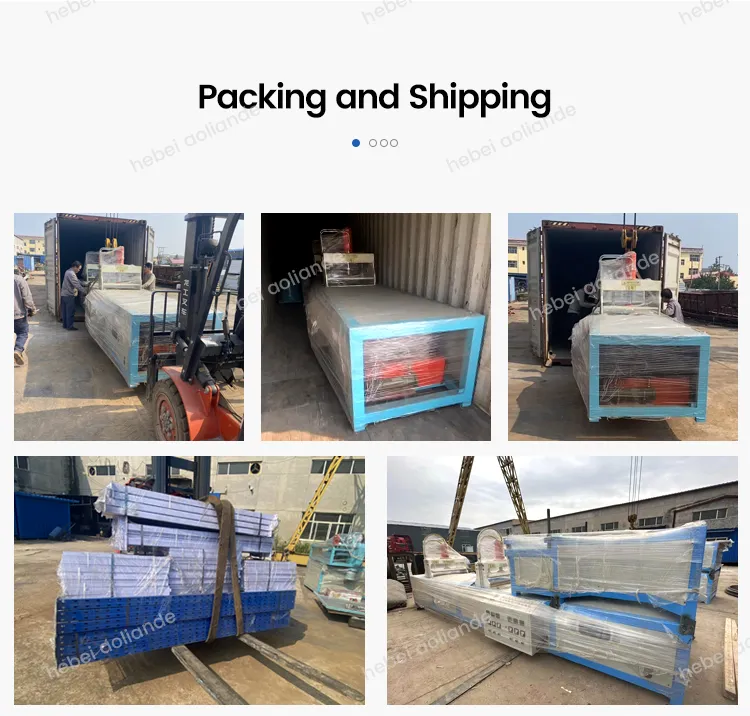

Hebei Aoliande chemical Equipment co., Ltd, is a professional company selling FRP pipes, FRP storage tanks, FRP molding products and FRP production machinery, the company through continuous development and introduction of professional and technology, relying on advanced technology, exquisite technology, reliable quality and perfect service, passed ISO9001, ISO14001 management system certification, now we have more than 50 employees, the annual sales of FRP series products reached 5,000,000 us dollars. Products have been sold all over the world, the United states, Brazil, Japan, Germany.India, Malaysia, Egypt, etc., won the support and trust of new and old customers.

"Efficient and easy to operate, with Aoliande customer service ensuring that we always have the help we need."

"The FRP Pultrusion Profile Machine offers great efficiency and precision in every profile produced."

"We rely on the FRP Pultrusion Profile Machine for high-quality profiles that meet all standards."

"Efficient and consistent, the FRP Pultrusion Profile Machine has greatly improved our production."