This FRP rebar machine mainly consists of yarn frame, dipping tank, winding, oven, traction machine, cutting saw and stacking device.

1. Yarn frame: Placing the yarn group, assembled split type, easy to in stall.

2. Dipping tank: Welded with stainless steel material, with internal pressure roller to make the roving fully impregnated in the resin.

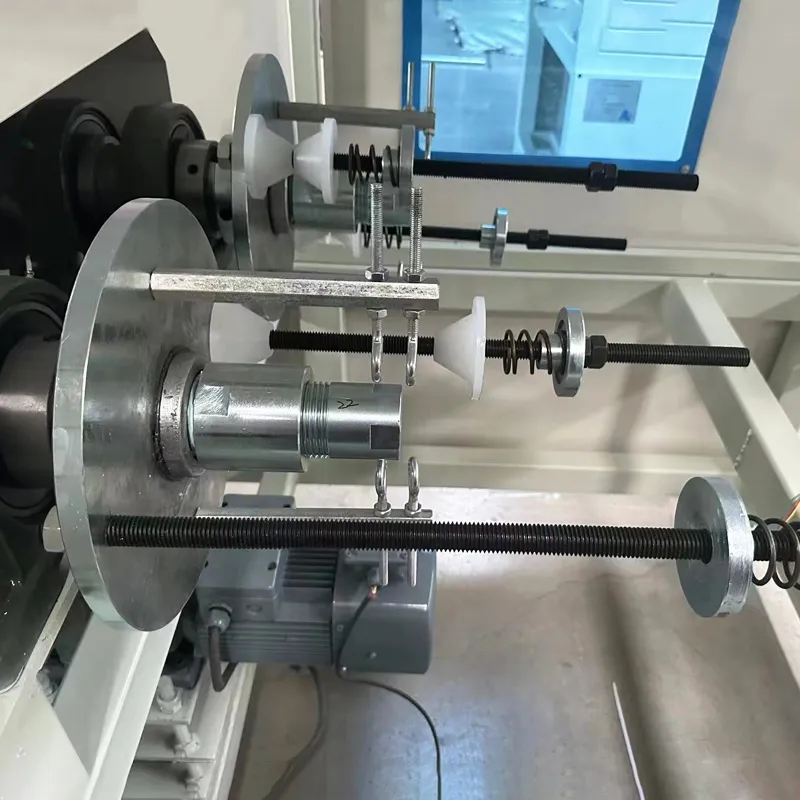

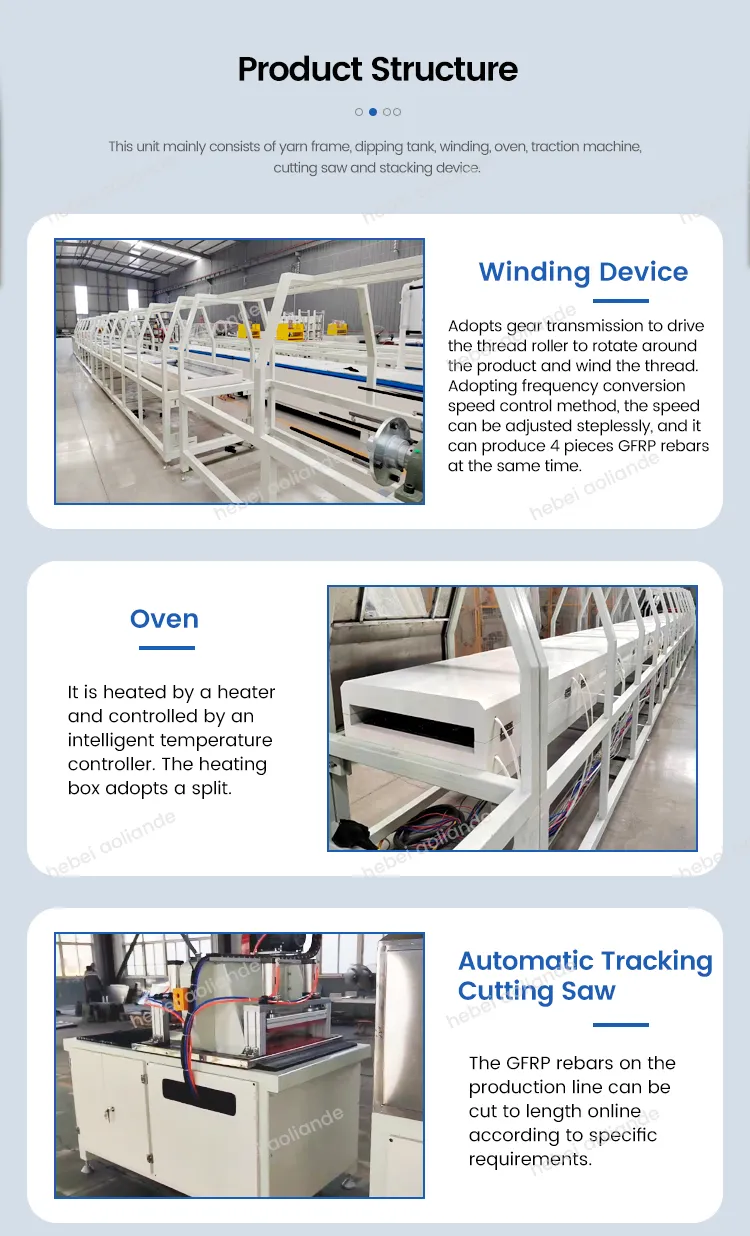

3. Winding device: Adopts gear transmission to drive the thread roller t o rotate around the product and wind the thread. Adopting frequency conversion speed control method, the speed can be adjusted steplessly, and it can produce 4 p i e c e s G F R P rebars at the same time.

4. Oven: It is heated by a heater and controlled by an intelligent temperature controller. The heating box adopts a split structure, which can be easily opened to clean up dripping resin, and the interior is filled with heat insulation materials.

5. Automatic tracking cutting saw: The GFRP rebars on the production line can be cut to length online according to specific requirements.

6. Product stacking rack : After cutting, the GFRP rebars are stacked and taken away by production personnel for stackin.

|

Type |

Produce Diameter Range |

|

2 lines FRP rebar machine |

DN4-40mm |

|

4 lines FRP rebar machine |

DN4-32mm |

|

5 lines FRP rebar machine |

DN4-26mm |

1. High tensile strength: The tensile strength of glass fiber reinforcement is better than that ofordinary steel bars, which is 20% higher than that of steel bars of the same specification, and has good fatigue resistance.

2. Light weight: The quality of glass fiber reinforcement is only 1/4 of the same volume of steel and the density is between 1.5 and 1.9(g/cm3).

3. Strong corrosion resistance: Corrosion resistance of chemicals such as acid and alkali can resist the corrosion of chloride ions and low pH solutions, especially the corrosion resistance of carbon compounds and chlorine compounds.

4. Strong material binding force: The thermal expansion coefficient of glass fiber reinforcement is closer to cement than steel, because glass fiber reinforcement and concrete have stronger binding force.

5. Strong designability: The elastic modulus of the glass fiber ribs is stable, the size is stable under thermal stress, and the bending and other shapes can be heat-formed arbitrarily,and the safety performance is good. There wil be no sparks when colliding with metal.

6. Strong magnetic permeability: The glass fiber reinforcement is a non-magnetic material.and it is not necessary to demagnetize the non-magnetic or electromagnetic concrete components.

7. Convenient construction: The glass fiber reinforcement can produce various standard andnon-standard parts with different sections and lengths according to user requirements. Non-metallic tension bands can be used for on-site binding, which is simple to operate.

Hebei Aoliande chemical Equipment co., Ltd, is a professional company selling FRP pipes, FRP storage tanks, FRP molding products and FRP production machinery, the company through continuous development and introduction of professional and technology, relying on advanced technology, exquisite technology, reliable quality and perfect service, passed ISO9001, ISO14001 management system certification, now we have more than 50 employees, the annual sales of FRP series products reached 5,000,000 us dollars. Products have been sold all over the world, the United states, Brazil, Japan, Germany.India, Malaysia, Egypt, etc., won the support and trust of new and old customers.

"The FRP Rebar Making Machine is easy to use and highly efficient, producing top-quality rebar quickly."

"We’ve seen significant improvements in output with the Aoliande FRP Rebar Making Machine."

"The Rebar Making Machine has been a great addition to our plant, and Aoliande’s technical support ensures everything runs smoothly."