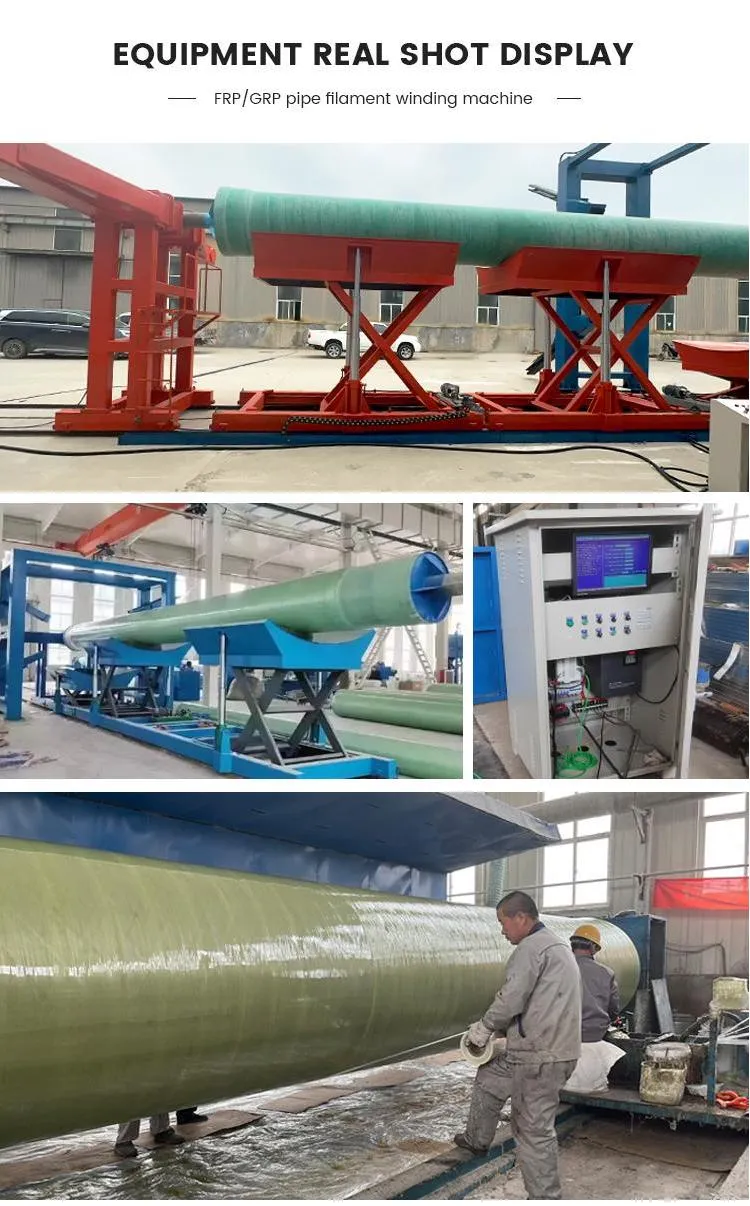

FRP/GRP pipe flament winding machine has six parts, such as inner layer manufacturing machine, computer control adding mortar-winding machine, curing station, repairing machine,mould unloading machine and resin mix station. its controlling center has been adopted the Taiwan's advanced STD industrial control computer. if the parameter of the wound products being inputted the computer, the design of the linearity for winding of the product will be finished automatically, then controlling the combined movements between the mound rolling speed and the running of the carriage. The pipes produced by the adding mortar-winding machine can decrease the cost and improve the stiffness through adding the mortar with outbad influences upon the leak-proof layer and the structure layer.

The RPM pipe's cost has decreased 40% than the common FRP pipe; the stiffness has been improved greatly. lt has many advantages, such as lightweight, anti-corrosion, lower roughness and proper price. it can be widely used in water supply and drainage, agricultural irrigation, petrochemical industry, ocean development, sewage treatment, etc. The production line annual capacity is 5000t, and reasonable structures, latest design, operate easily, high-grade automation are its characteristics. lt got the good valuation from the clients.

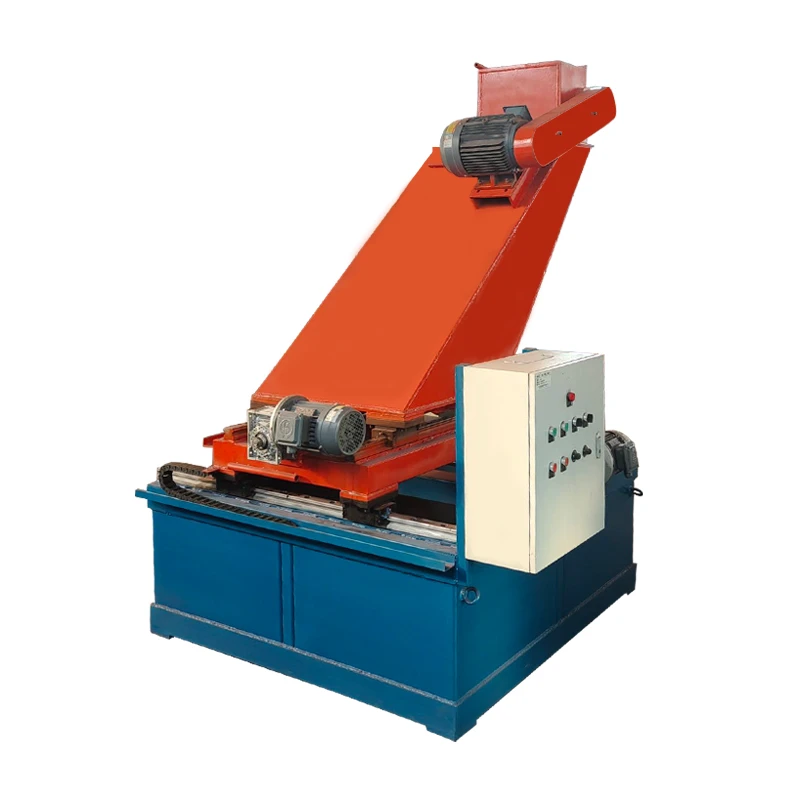

QFW-4000 FRP/GRP pipe filament winding machine

The main parameters:

1) The total power: 193.6kw

2) The maximum diameter can be manufactured: DN4000mm

3) The effective length of the pipe: 12000mm

4) The productivity: 1000kg/h

5) The baking board's temperature of curing station: 105~160 ºC

6) The maxi speed of conveying roving: 90m/min

7) The maxi width of roving sheet: 200mm

8) The maxi speed of sand conveyance: 100kg/min

9) The maxi mould-unloading force: 83t

10) The rated drawing force of the capstan: 5t

11) The rated lifting force of the supporting pipe trolley: 40t

12) The rated pressure of the hydraulic system: 16Mpa

13) The central height of mould-unloading machine: 2000mm

14) The central height of the other single machine: 1500mm

Note: If the indoor temperature is above 15ºC in winter, the baking board can be power-off, then the total power is 97.6kw

|

Model |

Diameter Range(mm) |

Pipe Length |

|

QFW-300 |

DN15-300 |

1.5m, 2m, 3m, 4m, 6m |

|

QFW-1200 |

DN300-1200 |

3m, 6m, 9m, 12m |

|

QFW-2500 |

DN300-2500 |

3m, 6m, 9m, 12m |

|

QFW-3200 |

DN300-3200 |

3m, 6m, 9m, 12m |

|

QFW-4000 |

DN300-4000 |

3m, 6m, 9m, 12m |

Hebei Aoliande chemical Equipment co., Ltd, is a professional company selling FRP pipes, FRP storage tanks, FRP molding products and FRP production machinery, the company through continuous development and introduction of professional and technology, relying on advanced technology, exquisite technology, reliable quality and perfect service, passed ISO9001, ISO14001 management system certification, now we have more than 50 employees, the annual sales of FRP series products reached 5,000,000 us dollars. Products have been sold all over the world, the United states, Brazil, Japan, Germany.India, Malaysia, Egypt, etc., won the support and trust of new and old customers.

"The FRP Pipe Winding Machine produces high-quality pipes, and Aoliande team has always been there with timely support."

"Excellent performance and responsive support from Aoliande—this machine has helped us optimize our production."

"We’ve been using this machine for a while, and it’s been a fantastic experience—efficient production and great service."