Mannheim process Sodium sulfate making machine is well-known as there are two kind of popular methods to be used to produce Sodium sulfate Product, one is Double decomposition method, the reaction is not good, the product quality should be improved. Another method is the Mannheim furnace process, it is used widely, but there are some difficulties occurred during the production.

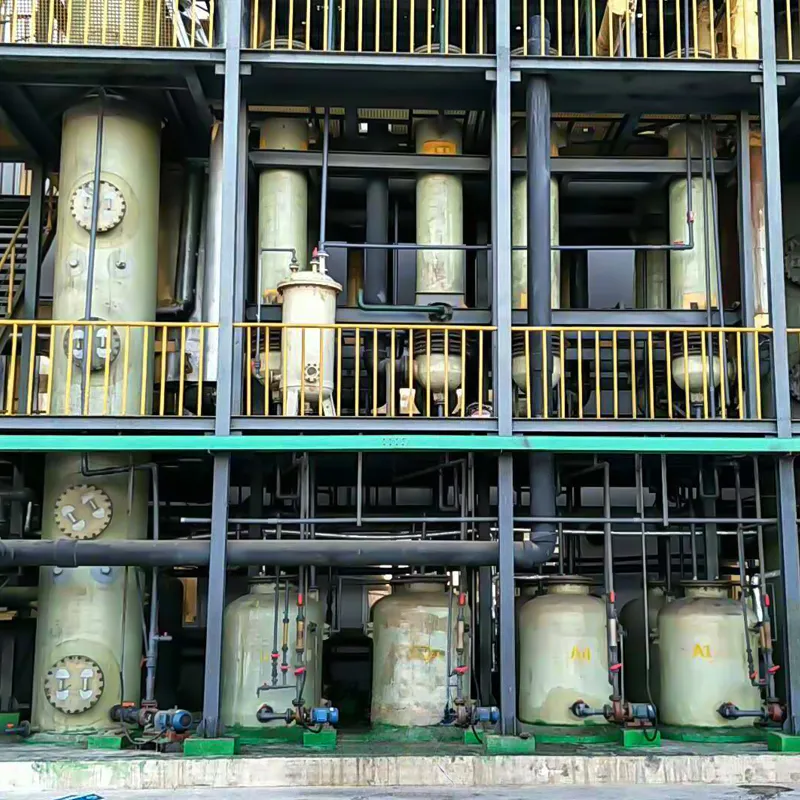

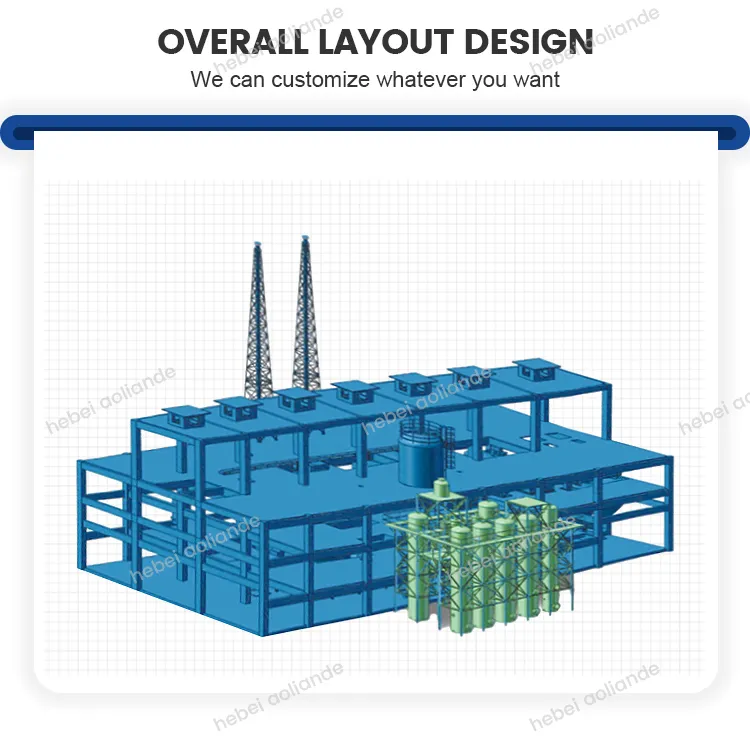

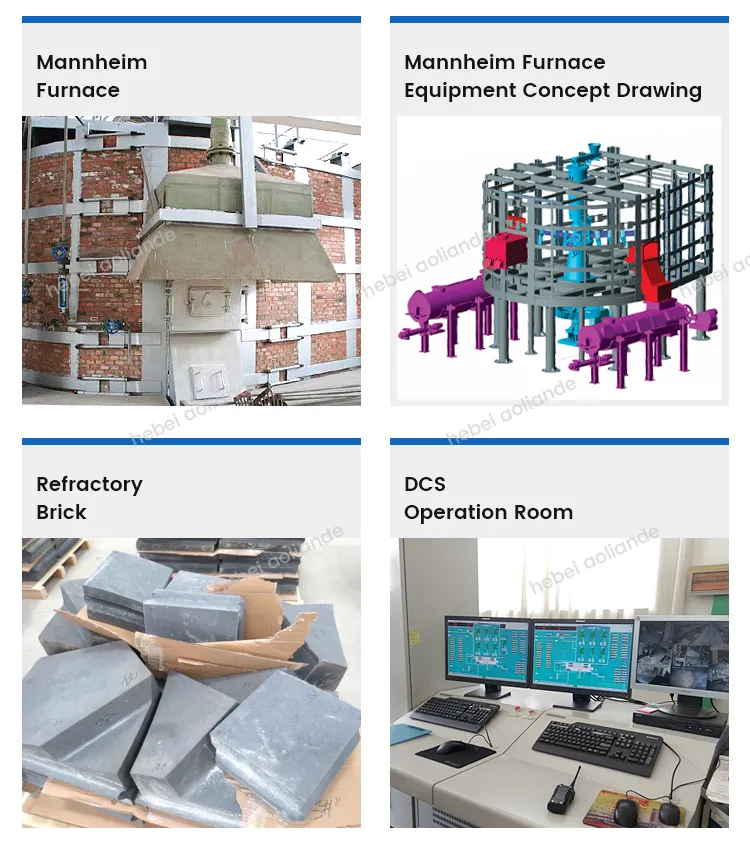

We had made the necessary and important improvement and perfection on its production equipment and production process of Mannheim furnace, to form a unique and perfect Sodium sulfate production technology now, improve the construction and material of furnace to achieve even heating, complete reaction and low energy consumption. New material and technology is applied to the part of hydrochloric acid absorption, thus absorption efficiency is enhanced and environmental issue is also well resolved.

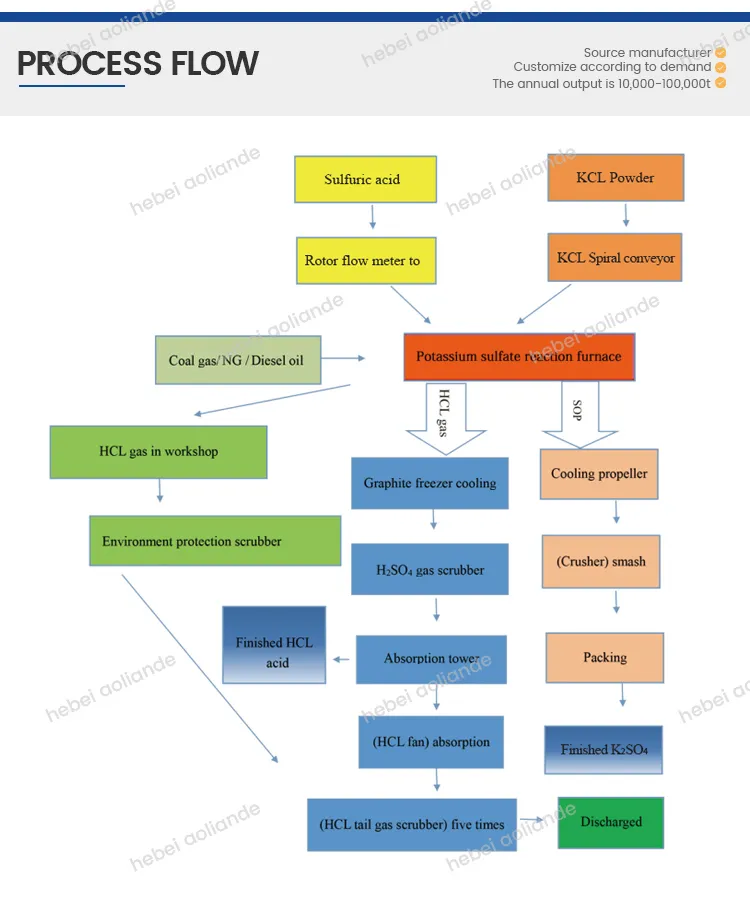

The most common method of producing sodium sulfate is the Mannheim Process, which is the reaction of potassium chloride with sulphuric acid at high temperatures. The raw materials are poured into the centre of a muffle furnace heated to above 600ºC.

Potassium Sulfate is produced along with hydrochloric acid in a two-step reaction via potassium bisulphate. This method for creating SOP accounts for 50% to 60% of global supply. The Mannheim Process is also the most expensive of the processing techniques due to the high input costs associated with purchasing MOP and sulphuric acid. This means that the final product costs about $500 per ton.

1. Some key components of our potassium sulfate fertilizer equipment are made of special materials which are corrosion resistant and durable. Hence, this fertilizer equipment also features long service life.

2. Waste recovery system to recycle hydrochloride acid (HCl) and meet environment requirements

3. Adjusted original HCl absorption system, improved on the quality of the final product.

4. Improved the flue design in the furnace which can make full use of energy and save energy consumption.

5. Used PLC automatic control system to control manufacturing the products, adjust the ratio of feedstock, and saved the labor cost.

6. Adopt gas generator replacing other heating method.

7. Stable production and easy operation.

8. Large output& Low coal consumption.

Hebei Aoliande chemical Equipment co., Ltd, is a professional company selling FRP pipes, FRP storage tanks, FRP molding products and FRP production machinery, the company through continuous development and introduction of professional and technology, relying on advanced technology, exquisite technology, reliable quality and perfect service, passed ISO9001, ISO14001 management system certification, now we have more than 50 employees, the annual sales of FRP series products reached 5,000,000 us dollars. Products have been sold all over the world, the United states, Brazil, Japan, Germany.India, Malaysia, Egypt, etc., won the support and trust of new and old customers.

"This Sodium Sulfate Production Line runs smoothly, consistently delivering high-quality results."

"The Sodium Sulfate line is a game-changer, boosting our production and reducing downtime."

"We trust the Sodium Sulfate Production Line to keep our factory running without issues."

"The Sodium Sulfate Production Line is highly efficient, and the Aoliande team was there for us every step of the way, from installation to operation."