FRP (Fiber Reinforced Plastic) profile machines are advanced manufacturing tools designed to produce high-quality, custom-shaped profiles for a variety of industrial applications. These machines utilize filament winding, pultrusion, or extrusion technologies to create FRP profiles with exceptional strength, durability, and resistance to corrosion. With the ability to produce profiles in a wide range of shapes, sizes, and materials, FRP profile machines are commonly used in industries such as construction, automotive, aerospace, and energy. The automated production process ensures consistent quality and precision, while the use of lightweight yet strong composite materials makes the resulting profiles ideal for applications requiring resistance to harsh environmental conditions, chemicals, or high temperatures. These machines offer versatile solutions for producing everything from beams, rods, and channels to more intricate custom profiles, making them a valuable asset for manufacturers seeking cost-effective, high-performance components. Additionally, FRP profile machines are designed for energy efficiency, providing a sustainable option for producing durable and long-lasting profiles with minimal material waste. Whether for structural components, reinforcement profiles, or specialized products, FRP profile machines are essential for creating reliable, high-strength materials that meet the diverse needs of modern industries.

Revolutionizing Manufacturing: The Impact of FRP Profile Machines on Industrial Production

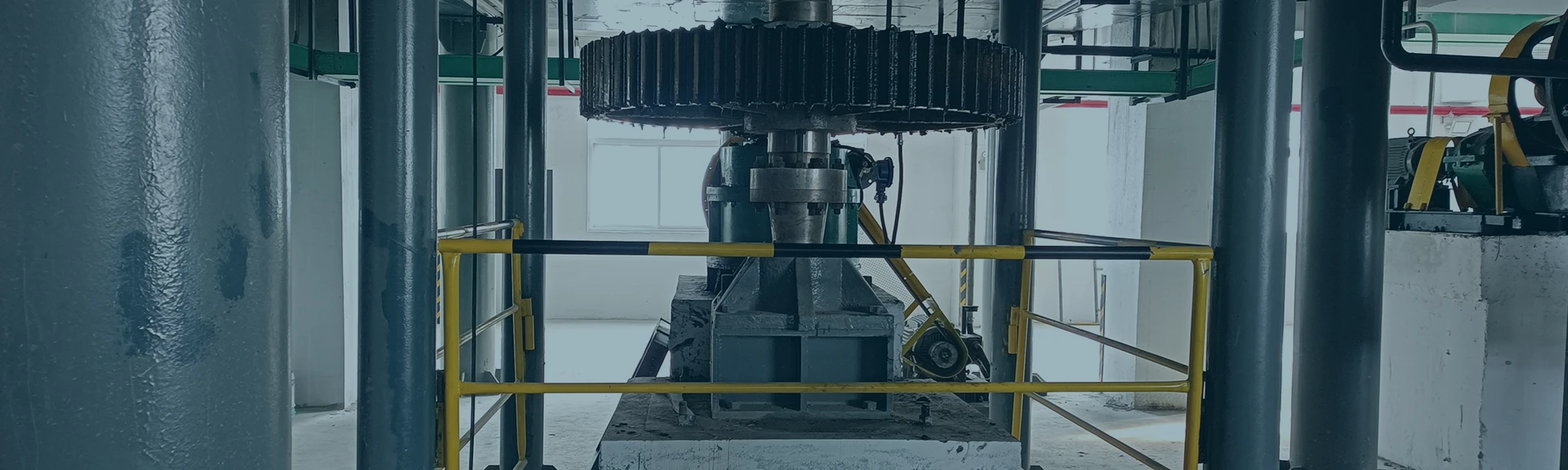

FRP (Fiber Reinforced Plastic) profile machines have significantly transformed industrial production, offering enhanced efficiency, precision, and versatility in creating composite materials. These machines employ advanced technologies such as filament winding, pultrusion, and extrusion to manufacture high-performance profiles used in various industries, including construction, automotive, aerospace, and energy.

One of the most notable impacts of FRP profile machines is their ability to produce strong yet lightweight materials. The profiles produced are resistant to corrosion, chemicals, and environmental wear, making them ideal for harsh industrial conditions. This durability not only extends the lifespan of products but also reduces the need for frequent maintenance, leading to lower long-term operational costs.

The versatility of FRP profile machines is another key benefit. They can produce profiles in a wide array of shapes and sizes, allowing manufacturers to meet the specific demands of diverse applications. Whether it’s beams, rods, or more intricate custom profiles, these machines ensure consistency and precision across all production runs. This capability has opened new opportunities for innovation, particularly in sectors that require specialized or high-performance components.

Moreover, FRP profile machines contribute to sustainability in manufacturing. These machines are designed for energy efficiency and minimal material waste, reducing environmental impact while still delivering high-quality, durable profiles. The automated nature of these machines further increases production speed and reduces human error, leading to higher throughput and improved overall efficiency.

FRP Profile Machines in the Automotive Industry: Lightweight, Strong, and Durable Components

The automotive industry has long been focused on enhancing vehicle performance while reducing weight to improve fuel efficiency and emissions. FRP (Fiber Reinforced Plastic) profile machines are playing a pivotal role in this evolution by enabling the production of lightweight, strong, and durable components that are transforming vehicle design and manufacturing.

FRP profile machines use advanced manufacturing techniques such as pultrusion and filament winding to create custom profiles from high-strength fibers and resins. These profiles are not only lightweight but also exhibit excellent resistance to corrosion, wear, and high temperatures. This makes them ideal for producing automotive components such as structural reinforcements, bumpers, and chassis parts that require both strength and durability without adding unnecessary weight to the vehicle.

The use of FRP components in vehicles contributes directly to improved fuel efficiency and reduced emissions. Lighter vehicles require less energy to operate, thus lowering fuel consumption and reducing the environmental impact of transportation. Additionally, FRP profiles are highly resistant to rust and corrosion, which extends the lifespan of components and reduces the need for frequent maintenance or replacement.

One of the standout features of FRP profile machines is their ability to create complex shapes and custom designs. Automotive manufacturers can now produce parts with intricate geometries that would be difficult or impossible to achieve with traditional materials like metal. This level of design flexibility allows for more innovative vehicle designs and the development of parts that offer better performance and aesthetic appeal.