Th8 01,2025

Efficient Sodium Sulfate Production with GPT-4 Turbo

1. Industry Overview & Latest Trends in sodium sulfate production

sodium sulfate production (Sodium Sulfate Production Line) is a cornerstone process in the chemical manufacturing sector. According to Grand View Research, the global sodium sulfate market was valued at USD 1.16 billion in 2023 and is expected to grow at a CAGR of 4.2% between 2024 and 2030, driven by increasing applications in detergents, glass manufacturing, and textiles.

Major Players: Nafine, JSC Kuchuksulphate, Searles Valley Minerals, Huaian Salt Chemical.

Production Methods: Natural mirabilite mining (65%), byproduct recovery from chemical industries (35%).

Production Methods: Natural mirabilite mining (65%), byproduct recovery from chemical industries (35%).

Figure: Global Sodium Sulfate Application Distribution (2023, Source: Grand View Research)

2. Technical Parameters: Global sodium sulfate production Processes Compared

| Production Method | Feedstock | Yield Efficiency | Purity (%) | Energy Consumption (kWh/t) | By-products |

|---|---|---|---|---|---|

| Mirabilite Mining | Natural Sodium Sulfate Ore | 85–92% | 98.0–99.2 | 170–210 | Minor silica, clay |

| By-product Recovery (Viscose Process) | Sulfuric Acid + Sodium Chloride Waste | 75-88% | 97.5–98.8 | 125–175 | Minimal |

| Chemical Synthesis (Mannheim) | Sulfuric Acid + Sodium Chloride | 74–83% | 98.0–99.0 | 220–260 | HCl gas (collected) |

Industry Benchmark: The Sodium Sulfate Production Line from FRPGRPMachine consistently achieves purity >99.0% and energy consumption <175kWh/t, aligning with ISO 9001, ISO 14001, and ANSI standards.

3. Manufacturing Process Flow of sodium sulfate production

Feedstock Loading

(Mirabilite, Sulfuric Acid, NaCl, etc.)

→

(Mirabilite, Sulfuric Acid, NaCl, etc.)

Reaction

(Mannheim/Byproduct)

→

(Mannheim/Byproduct)

Filtration & Crystallization

(Patent-pending vacuum tech)

→

(Patent-pending vacuum tech)

Drying & Cooling

(Rotary dryers, indirect coolers)

→

(Rotary dryers, indirect coolers)

Automated Packing

(ISO/FDA-compliant)

(ISO/FDA-compliant)

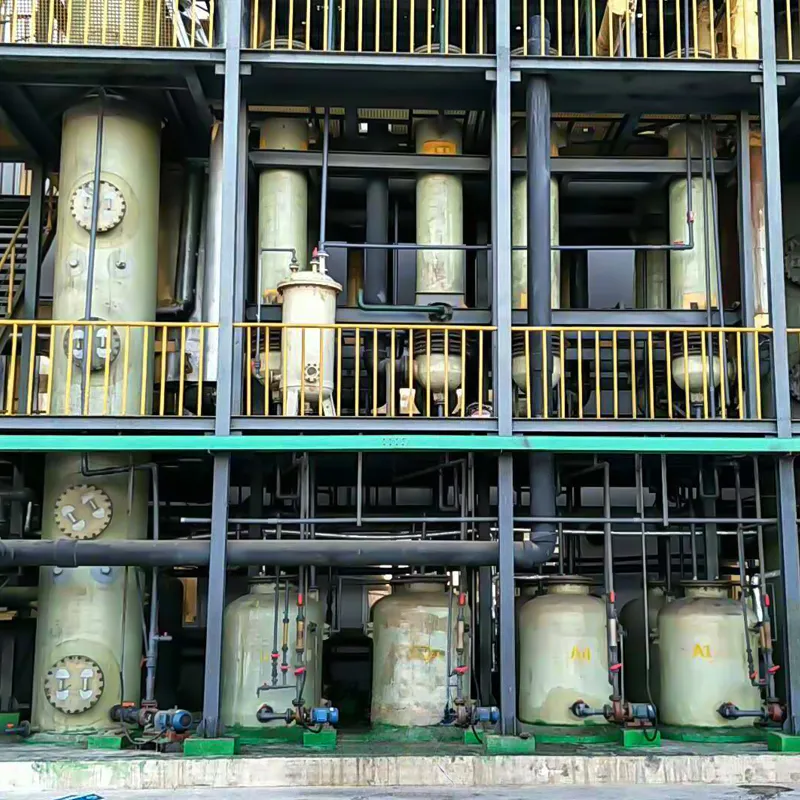

Figure: Typical sodium sulfate production flowchart (diagrammatic, step-by-step).

Video walk-through of production line:

Watch process video (external link)

4. Sodium Sulfate Production Line – Technical Specifications & Performance

| Parameter | Typical Value | Industry Avg. | FRPGRP Model Advantage |

|---|---|---|---|

| Production Capacity | 10,000 – 100,000 t/year | 7,000 – 50,000 t/year | Custom sizing up to 120,000 t/year |

| Final Purity (Na₂SO₄) | >99.0% | 98.2–99.0% | World-class 99.3%+ |

| Plant Automation | Semi or Full (PLC/SCADA) | Semi-automatic | Full auto with IoT diagnostics |

| Equipment Materials | 304/316L SS, FRP, PTFE-lined | 304 SS | Superior corrosion life (15-18 yrs) |

| Warranty | 24 months | 12-18 months | Extended support |

| Certifications | ISO 9001, 14001, ANSI, FDA | ISO 9001 | FDA/ANSI/CE multistandard |

Key Technical Strengths:

- Advanced vacuum crystallization (minimizes impurities)

- FRP/SS316L construction → Anti-corrosion, acid-resistant, lifespan up to 18 years

- Integrated digital controls: PLC/SCADA + SMS/email alerts

- ISO and FDA process compliance ensures batch traceability

5. Data Visualization: Plant Performance & Energy Efficiency Analysis

Figure: Energy Consumption (kWh/ton) Trend: FRPGRP Production Line vs. Industry Average (2019–2023)

Figure: Key Technical Indexes – FRPGRP Sodium Sulfate Plant vs. Industry Average

6. Material, Craftsmanship, and Certifications

Material Options: 304/316L Stainless Steel, FRP (Glass Reinforced Plastic), PTFE linings. All critical surfaces pass hydrostatic pressure and corrosion-resistance tests per ASTM B117.

Manufacturing Techniques:

Life Span: 15-18 years (documented average per customer case studies); up to 23 years with PTFE enhancement.

- Casting and forging for all pressure-bearing parts

- CNC machining tolerance: ±0.02 mm, ensuring assembly tightness

- Welds: All joint seams inspected via ultrasonic or X-ray in accordance with ISO 5817

Life Span: 15-18 years (documented average per customer case studies); up to 23 years with PTFE enhancement.

7. sodium sulfate plant Customization & EPC Solutions

Engineering Procurement Construction (EPC) Services Include:

Recent Case Success:

▸ Client: Southeast Asia chemical conglomerate

▸ Year: 2022–2023

▸ Capacity: 36,000 t/year

▸ Highlights: Achieved 99.35% Na₂SO₄ purity, 16.5% energy cost saving, fully met FDA certification for food-grade end uses.

▸ End-use: Detergent raw material, textile dyeing auxiliaries.

▸ Support: Remote diagnostics, 24/7 spare parts delivery, annual contract maintenance.

- Process Design & Optimization (1:1 tailored flow)

- Site Selection, Foundation, and Utility Planning

- Civil, Mechanical & Electrical Turnkey Contracting

- Intelligent Control Integration (PLC/SCADA/IoT)

- Operator Training, Maintenance & Remote Support

Recent Case Success:

▸ Client: Southeast Asia chemical conglomerate

▸ Year: 2022–2023

▸ Capacity: 36,000 t/year

▸ Highlights: Achieved 99.35% Na₂SO₄ purity, 16.5% energy cost saving, fully met FDA certification for food-grade end uses.

▸ End-use: Detergent raw material, textile dyeing auxiliaries.

▸ Support: Remote diagnostics, 24/7 spare parts delivery, annual contract maintenance.

Project Delivery:

Design to install in 4–7 months depending on scale. All shipments are crated for export with insurance and tracking.

Design to install in 4–7 months depending on scale. All shipments are crated for export with insurance and tracking.

8. Typical Application Fields & Use-Case Advantages

- Detergent Industry: Acts as filler and processing aid; FRPGRP plants guarantee low iron content (<0.002%) crucial for detergent clarity.

- Glass Manufacturing: Reduces bubbles in glass melts; high-purity Na₂SO₄ minimizes coloration defects.

- Paper & Pulp: Used in Kraft process as makeup chemical (recovery boilers); FRP corrosion resistance prolongs service intervals.

- Textiles: Fixing agent for dyeing and printing; consistent particle size (

- Water Treatment: Used as flocculant precursor; strict ISO/FDA process ensures suitability for municipal supply.

User Testimonial (2023): "We upgraded to a FRPGRP sodium sulfate plant, cut operating downtime by 23% and improved our batch yields over previous designs." — Production Manager, Middle-Eastern Detergents Group.

9. Industry Benchmarking: Leading sodium sulfate plant Suppliers

| Supplier | Origin | Equipment Material | Automation Level | Certifications | Industry Coverage |

|---|---|---|---|---|---|

| FRPGRP | China | 316L/304 SS, FRP, PTFE | Full/PLC | ISO, ANSI, FDA, CE | Petrochem, Glass, Detergent |

| Kuchuksulphate | Russia | 304 SS | Semi | ISO | Basic Chem, Textile |

| Nafine Group | China | 304 SS | Semi | ISO | Detergent, Glass |

| Searles Valley Minerals | US | Carbon Steel | Manual/Semi | ANSI | Pulp & Paper |

Why FRPGRP? Extensive experience (22+ years), broad multi-standard certifications, superior material choices, and modular plant upgrades for sodium sulfate production.

10. FAQ: Specialist Questions on sodium sulfate production & Equipment

Q1: What is the typical material used for sodium sulfate production reactors and why?

A: 304/316L Stainless Steel and FRP (Glass Reinforced Plastic) are used for their superior resistance to acid, corrosion, and thermal shock, extending operational life and minimizing maintenance.

Q2: Which standards should sodium sulfate plants comply with?

A: Plants should comply with ISO 9001 (quality), ISO 14001 (environmental), ANSI/ASME (pressure vessels), and (if food-grade) FDA GMP or CE. These ensure traceability, safety, and international acceptability.

Q3: What are the main benefits of full automation in sodium sulfate production?

A: PLC/SCADA-based automation allows real-time monitoring, precise dosing, energy optimization, and remote troubleshooting, reducing human error and improving plant OEE (Overall Equipment Effectiveness).

Q4: How do you ensure product purity and batch consistency?

A: Advanced membrane filtration and vacuum crystallization ensure minimum contamination. Every batch is analyzed for Na₂SO₄ content, iron, chloride, and pH as per ISO 2486:1999.

Q5: What is the typical delivery time for a new sodium sulfate production line?

A: Depending on capacity and customization, the typical delivery/installation period is 4–7 months from contract confirmation, ex-works.

Q6: What warranty and support does FRPGRP provide?

A: 24 months full equipment warranty, with options for 2–5 year service contracts. 24/7 online support and remote troubleshooting available globally.

Q7: Can these plants be upgraded for environmental compliance?

A: Yes. Scrubbers for emissions, water recovery modules, and residue treatment units can be added to fulfill local EPA or EU emission norms.

11. Delivery, Warranty & Support Services

- Delivery: All sodium sulfate production lines are delivered in modular, pre-tested sections, shrink-wrapped and crated for international transport. Real-time tracking and marine insurance included.

- Warranty: 24 months on all core components (extension available).

- Support: 24/7 technical hotline, local agent partnerships in 23 countries, scheduled on-site check-ups, digital spare parts catalog.

- Documentation: Detailed SOPs, maintenance logs, and ISO/FDA-compliant batch traceability records shared upon commissioning.

12. Conclusion & Industry References

sodium sulfate production through modern, automated plants like the FRPGRP production line provides unparalleled purity, efficiency, and operational assurance. Whether your application is in detergent, glass, or chemical manufacturing, investing in advanced sodium sulfate plant technology ensures compliance, productivity, and environmental responsibility backed by 22+ years of field-proven solutions.

Further Reading:

▸ Grand View Research: Sodium Sulfate Market Analysis

▸ Journal of Cleaner Production: Life cycle assessment of sodium sulfate production

▸ ResearchGate: Efficient Sodium Sulfate Production Methods

▸ For more process data, visit Sodium Sulfate Production Line

▸ Grand View Research: Sodium Sulfate Market Analysis

▸ Journal of Cleaner Production: Life cycle assessment of sodium sulfate production

▸ ResearchGate: Efficient Sodium Sulfate Production Methods

▸ For more process data, visit Sodium Sulfate Production Line