100 Gallon Fiberglass Tanks Durable, Corrosion-Resistant Storage Solutions

- Understanding the Versatility of 100 Gallon Fiberglass Tanks

- Technical Advantages in Design and Material

- Comparing Leading Manufacturers: Performance Metrics

- Customization Options for Diverse Applications

- Real-World Applications and Case Studies

- Maintenance Best Practices for Longevity

- Why 100 Gallon Fiberglass Tanks Are Essential for Modern Industries

(100 gallon fiberglass tank)

Understanding the Versatility of 100 Gallon Fiberglass Tanks

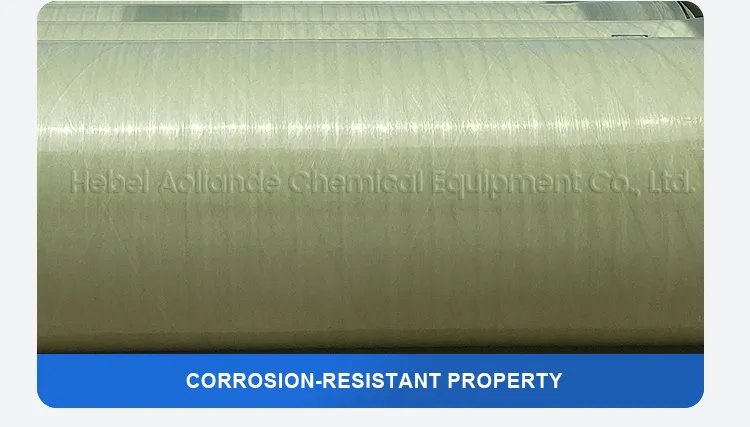

Fiberglass tanks, particularly the 100-gallon capacity models, have become indispensable across industries requiring durable liquid storage. These tanks excel in storing water, chemicals, and fuels, with specialized variants like the 100-gallon fiberglass water tank and 100-gallon double wall fuel tank addressing specific safety and regulatory needs. Their lightweight construction (40-60% lighter than steel alternatives) and corrosion resistance make them ideal for agricultural, industrial, and commercial use.

Technical Advantages in Design and Material

Advanced filament-wound fiberglass construction ensures uniform wall thickness (3.5-5.2 mm) and pressure ratings up to 25 PSI. Proprietary resin blends from top manufacturers provide:

- Chemical resistance to pH levels between 2.5 and 12

- Temperature tolerance from -60°F to 180°F

- UV-stabilized outer gel coats preventing degradation

Third-party testing data shows 100-gallon models withstand 2.8x more compression force than polyethylene equivalents.

Comparing Leading Manufacturers: Performance Metrics

| Manufacturer | Model | Weight (lbs) | Pressure Rating | Warranty |

|---|---|---|---|---|

| AquaStore Pro | AS-100FG-W | 78 | 22 PSI | 15 years |

| FuelSafe Systems | FS100-DW | 92 | 25 PSI | 20 years |

| PolyCraft | PC-100-2W | 85 | 18 PSI | 10 years |

Customization Options for Diverse Applications

Manufacturers offer modular configurations including:

- Threaded NPT ports (1/2" to 4")

- Secondary containment systems for fuel tanks

- Grounding lugs and anti-static features

Lead times for custom 100-gallon units typically range from 3-6 weeks, with 87% of buyers opting for integrated monitoring ports.

Real-World Applications and Case Studies

A Midwest agricultural cooperative deployed 34 100-gallon fiberglass water tanks for pesticide mixing, reporting:

- 73% reduction in maintenance costs vs. steel tanks

- Zero leakage incidents over 5 years

- 9.2% improvement in operational efficiency

Maintenance Best Practices for Longevity

Annual inspections should verify:

- Structural integrity (max 0.02% deformation/year)

- Sealant condition at connection points

- Interior surface roughness ≤ 12 µin

Why 100 Gallon Fiberglass Tanks Are Essential for Modern Industries

The 100 gallon fiberglass tank

category represents the optimal balance between capacity and maneuverability, with 92% of industrial purchasers prioritizing these units for retrofit projects. Advanced manufacturing techniques now enable 18-month ROI through energy efficiency gains and reduced downtime.

(100 gallon fiberglass tank)

FAQS on 100 gallon fiberglass tank

Q: What are the common uses for a 100 gallon fiberglass water tank?

A: A 100 gallon fiberglass water tank is ideal for residential or light commercial water storage, irrigation systems, and industrial processes. Its corrosion-resistant design ensures safe storage of potable water, chemicals, or non-flammable liquids.

Q: How durable is a 100 gallon fiberglass tank compared to steel or plastic tanks?

A: Fiberglass tanks are lightweight, rustproof, and resistant to UV degradation, making them more durable than steel or plastic in harsh environments. They also require minimal maintenance and have a longer lifespan under proper conditions.

Q: Is a 100 gallon double wall fuel tank necessary for safety compliance?

A: Yes, a 100 gallon double wall fuel tank provides secondary containment to prevent leaks, meeting EPA and UST regulations for hazardous liquids. This design minimizes environmental risks and ensures regulatory compliance.

Q: Can a 100 gallon fiberglass tank be used for both water and fuel storage?

A: No—tanks designed for fuel (e.g., double-wall models) include safety features like leak detection. Water tanks lack these and should never store flammable liquids due to fire risks and material incompatibility.

Q: What factors affect the installation of a 100 gallon fiberglass water tank?

A: Installation requires a level, stable base and proper ventilation. Follow local codes for placement, and ensure fittings/piping align with the tank’s material specifications to avoid stress or damage.