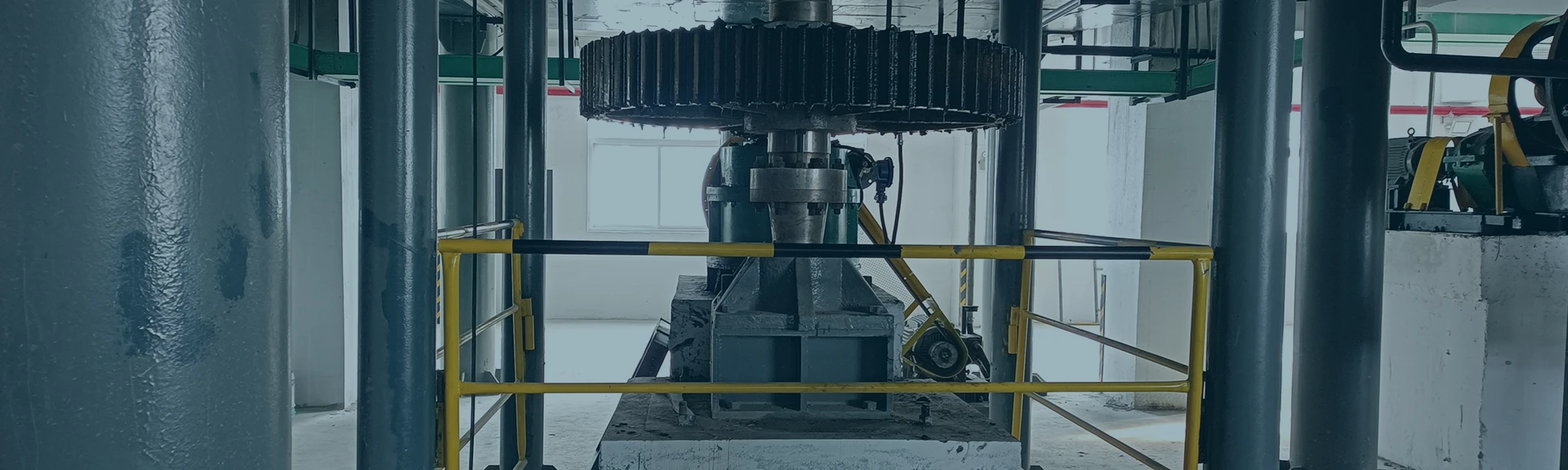

The Mannheim Furnace is an advanced industrial solution designed for the efficient production of high-quality products in the chemical and petrochemical industries. Known for its exceptional performance and reliability, this furnace is specifically engineered for processes such as the production of sulfuric acid, where high-temperature heat treatment and precise control are essential. The Mannheim Furnace utilizes a unique design that allows for optimal temperature distribution and fuel efficiency, reducing operational costs while maximizing throughput. Featuring robust construction and durable materials, it is built to withstand extreme operating conditions, ensuring a long service life and minimal maintenance. The furnace's advanced heat recovery system further enhances energy efficiency, contributing to lower environmental impact and improved sustainability. Ideal for large-scale operations, the Mannheim Furnace is a cornerstone of modern chemical production facilities, offering both versatility and cutting-edge technology to meet the demands of a rapidly evolving industry.

The Role of Mannheim Furnaces in Modern Chemical Plants: A Key Component for High-Temperature Processes

In modern chemical plants, the Mannheim furnace plays a pivotal role in various high-temperature processes, particularly in the production of sulfuric acid, one of the most widely used chemicals in industries such as agriculture, manufacturing, and energy. Known for its robust performance and efficiency, the Mannheim furnace is specifically designed to facilitate the efficient conversion of sulfur dioxide (SO₂) to sulfur trioxide (SO₃) in a controlled, high-temperature environment, a crucial step in sulfuric acid production.

The Mannheim furnace stands out due to its ability to maintain high temperatures (around 450-500°C), which are necessary for catalyzing the oxidation of sulfur dioxide. This makes it an indispensable piece of equipment for any large-scale sulfuric acid production facility. The furnace's design includes multiple heating zones that help ensure even temperature distribution, improving reaction efficiency and reducing energy consumption. By incorporating advanced heat recovery systems, the Mannheim furnace also minimizes fuel use, contributing to more sustainable and cost-effective operations.

Apart from sulfuric acid production, Mannheim furnaces are employed in a variety of other high-temperature applications, including the manufacture of chemicals, petrochemicals, and fertilizers. Their versatility, energy efficiency, and ability to withstand extreme operating conditions make them a critical component in the chemical production process. Moreover, the furnace's ability to integrate with other systems, such as waste heat recovery and sulfur recovery units, further enhances its role in modern chemical plants, promoting a more sustainable and environmentally friendly approach to industrial production.

Mannheim Furnace Design and Technology: Key Features for Enhanced Heat Recovery and Environmental Compliance

The Mannheim furnace is a cornerstone of modern chemical processing, particularly in the production of sulfuric acid. Its design and technology have evolved over time to meet the demands of energy efficiency, environmental sustainability, and operational performance. Among its key features, enhanced heat recovery systems and design innovations play a crucial role in reducing energy consumption and supporting environmental compliance.

One of the standout features of the Mannheim furnace is its advanced heat recovery capability. By capturing and reusing waste heat generated during the high-temperature processes, the furnace significantly reduces the need for additional fuel input, lowering operational costs and minimizing environmental impact. The heat recovery system ensures that excess heat is not wasted but instead repurposed to preheat incoming gases, creating a more energy-efficient process. This results in lower greenhouse gas emissions and reduced carbon footprints, aligning with global environmental regulations and sustainability goals.

Another critical aspect of Mannheim furnace design is its ability to operate under high temperatures while maintaining optimal reaction conditions for sulfur dioxide oxidation. The furnace uses a combination of refractory linings and advanced insulation to withstand extreme conditions, ensuring long-term durability and reduced maintenance needs. The precise control of temperature zones within the furnace also ensures that chemical reactions occur efficiently, improving overall production output and quality.

Additionally, modern Mannheim furnaces incorporate automated control systems that monitor key parameters such as temperature, pressure, and gas flow rates. This real-time monitoring enhances the furnace's ability to comply with strict environmental standards by ensuring that emissions stay within permissible limits.