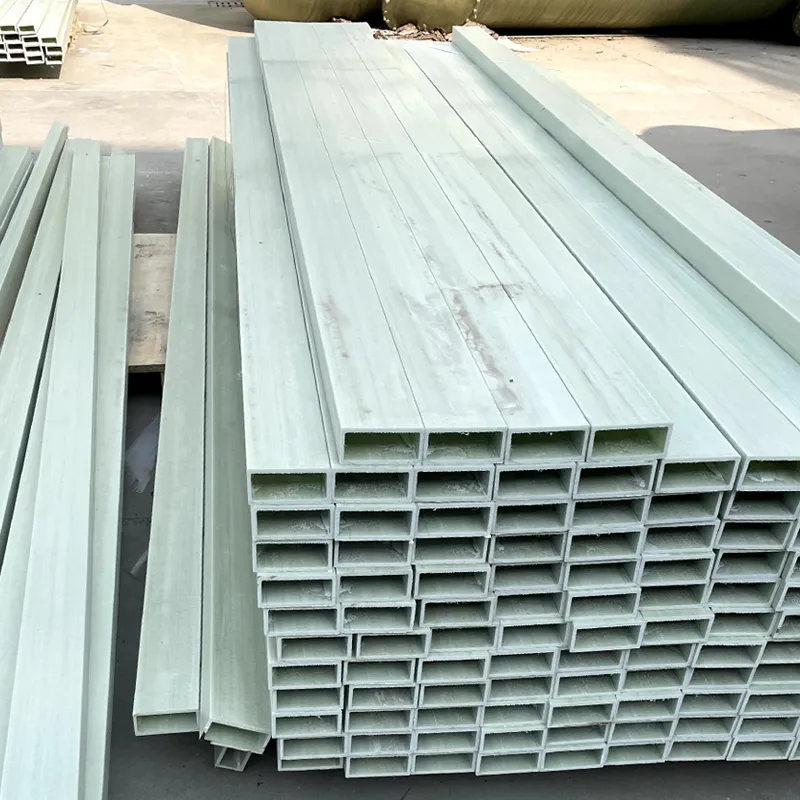

Pultrusion is a continuous process for the manufacture of products having a constant cross section, such as rods, beams, channels, tubing and structural shapes. Pultrusion produces profiles with extremely high fiber loading, thus pultruded products have high structural properties.

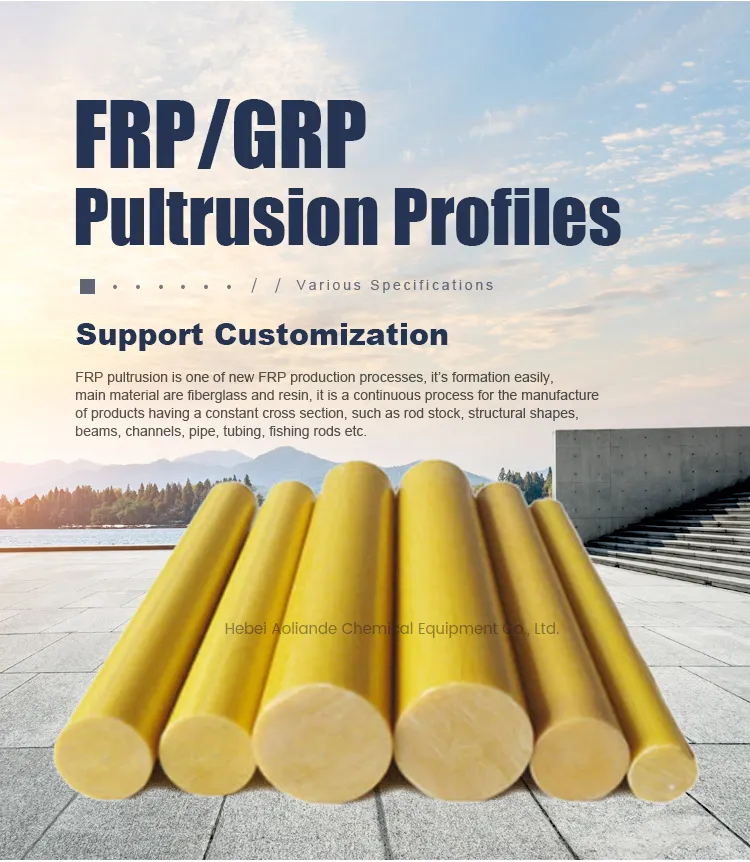

The basic components of the FRP profiles for resin and glass fiber (including cloth, carpet, etc.), which is based fibers (including glass fibers, carbon fibers, organic fibers and other metals, non-metallic fiber) as reinforcing material, resin (mainly epoxy polyester resins, phenolic resins) as crosslinking agent and other auxiliary materials supplemented (main materials: mold release agents, curing agents, catalysts, sealing mold agents, UV light stabilizers, mold clean water, gel coat and other ) composite made of.

Features of FRP Protrusion Profiles

It has a high temperature, corrosion resistance, high strength, low specific gravity, low moisture absorption, extending small and good insulation and a series of excellent properties. Widely used for mechanical structure, insulation, high-frequency mechanical parts and other functional structural components.

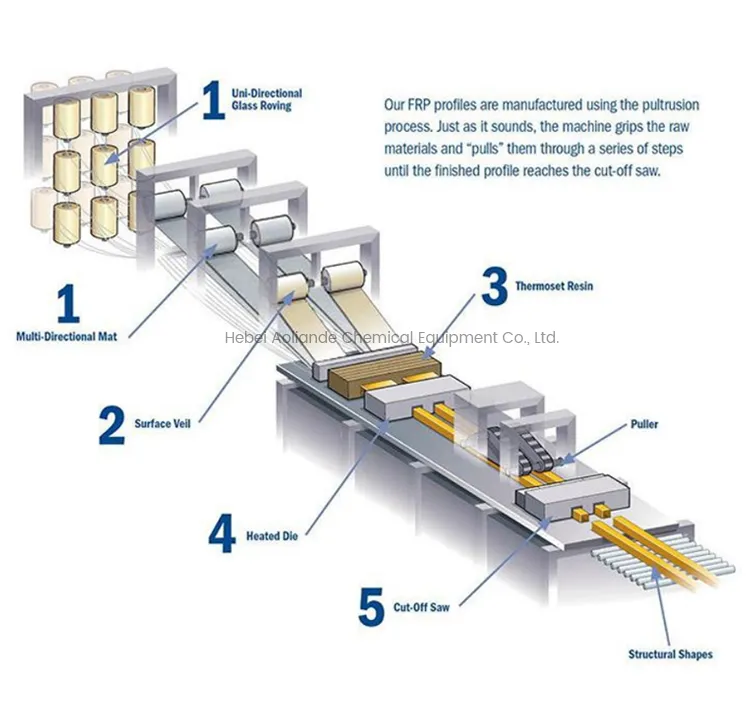

FRP Pultrusion Profile Production Process

The FRP pultrusion process is a continuous manufacturing method used to produce profiles with a constant cross-section, such as rods, beams, channels, and tubes. This process ensures high fiber loading, resulting in strong and durable profiles.

1. Raw Material Preparation

The process begins by selecting the appropriate reinforcement materials (e.g., glass fibers, carbon fibers) and resin (usually epoxy or polyester resin). Additional materials like curing agents and UV stabilizers are also prepared.

2. Impregnation

The reinforcement fibers are pulled through a resin bath, where they are fully impregnated with the resin, ensuring a strong bond between the fibers and resin for better mechanical performance.

3. Pultrusion Molding

The resin-soaked fibers are pulled into a heated mold using a pulling system. The heat helps the resin to cure, forming the profile’s desired shape. The continuous pulling ensures uniformity and stability of the profile.

4. Curing

The formed profile is heated to cure the resin, hardening it into a solid shape. The curing time and temperature are carefully controlled based on the resin type and profile requirements.

5. Cooling and Cutting

After curing, the profile is cooled to room temperature and then cut to the required lengths. Precision cutting ensures the product meets dimensional specifications.

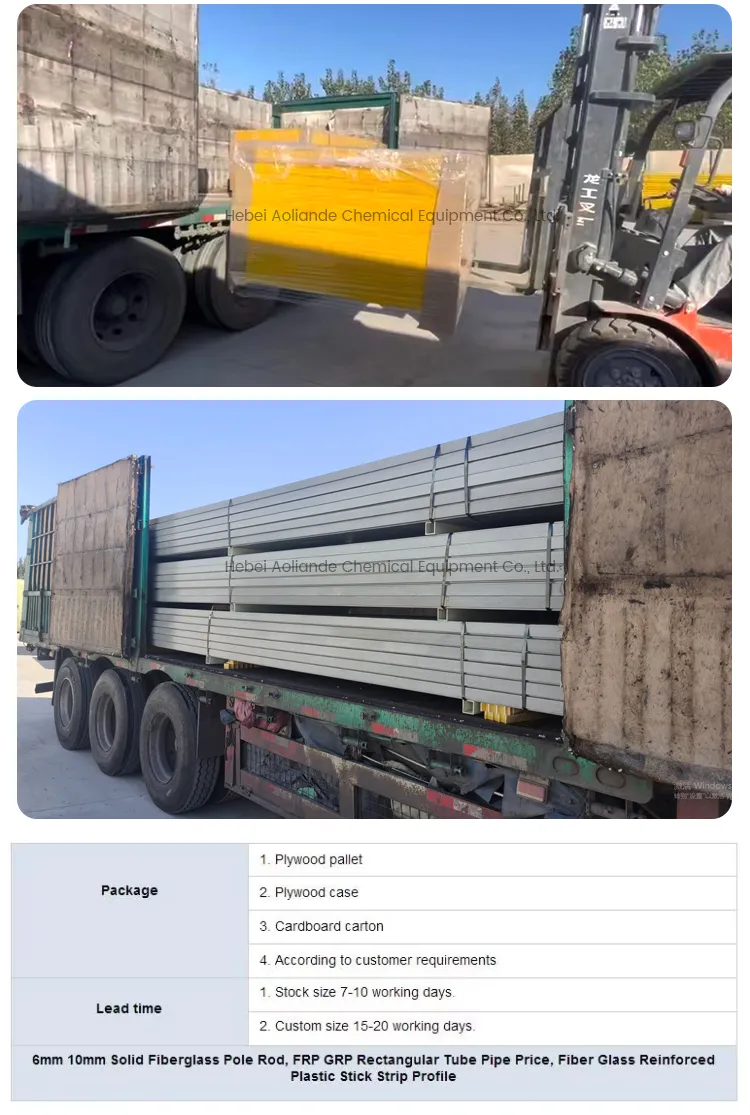

6. Inspection and Packaging

The final product undergoes quality checks for dimensions, surface finish, and mechanical properties. Once verified, the profiles are packaged and ready for shipment.

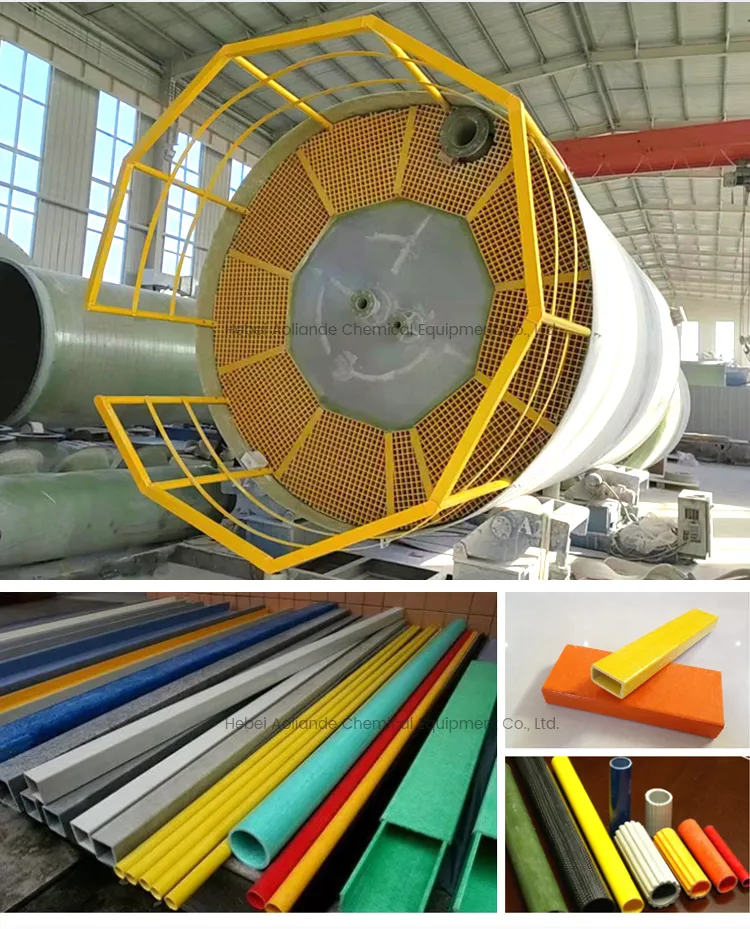

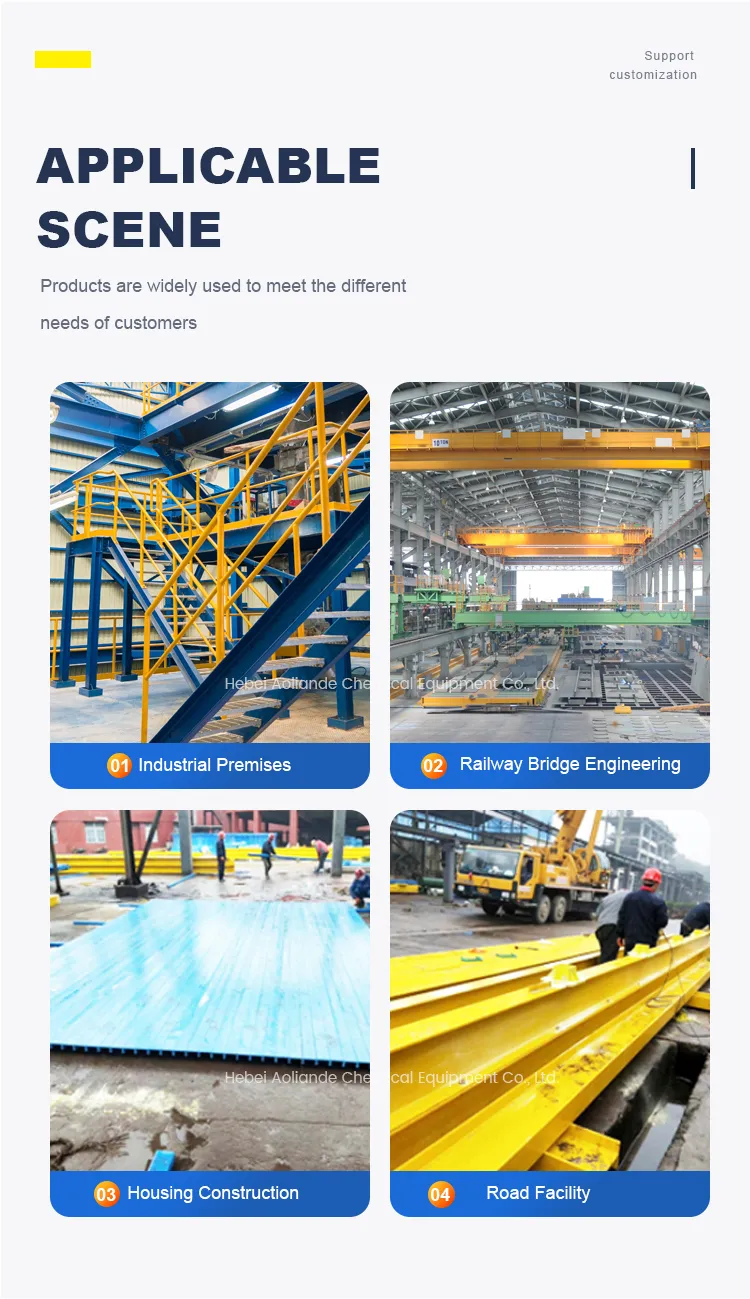

Profiles produced using the FRP pultrusion process are characterized by high strength, corrosion resistance, and lightweight properties. These qualities make pultruded profiles ideal for large-scale production and suitable for a wide range of industries, such as construction, transportation, energy, and environmental protection.

Hebei Aoliande chemical Equipment co., Ltd, is a professional company selling FRP pipes, FRP storage tanks, FRP molding products and FRP production machinery, the company through continuous development and introduction of professional and technology, relying on advanced technology, exquisite technology, reliable quality and perfect service, passed ISO9001, ISO14001 management system certification, now we have more than 50 employees, the annual sales of FRP series products reached 5,000,000 us dollars. Products have been sold all over the world, the United states, Brazil, Japan, Germany.India, Malaysia, Egypt, etc., won the support and trust of new and old customers.

"The FRP/GRP Pultruded Profiles have great durability, and the service from Aoliande’s team has been excellent."

"We’ve been using FRP Cable Trays from Hebei Aliande, and they’ve been high strength and flawless."

"Great strength and performance from FRP square tubes, making them ideal for our projects."