Best Price Vinyl Ester Resin Monolithic Casting FRP Electrolytic Cells

Advancing Industrial Processing with Superior Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price Solutions

In today's challenging industrial landscape, particularly within sectors such as chlor-alkali production, hydrometallurgy, and specialized chemical processing, the integrity and efficiency of electrolytic cells are paramount. Traditional materials often succumb to the highly corrosive and aggressive chemical environments, leading to frequent maintenance, operational downtime, and significant economic losses. This necessitates the adoption of advanced material solutions that offer unparalleled chemical resistance, structural stability, and an extended service life. The market trend is unequivocally moving towards high-performance composite materials, specifically Fiber Reinforced Polymer (FRP) composites, due to their superior properties compared to conventional metallic or lined steel structures. These materials effectively address the limitations of existing technologies by providing robust, long-lasting solutions for critical infrastructure, ensuring continuous and optimized production cycles. The strategic investment in such advanced materials directly translates to enhanced operational safety, reduced lifecycle costs, and improved environmental compliance, making them an indispensable component of modern industrial infrastructure. This shift is not merely about material replacement; it represents a fundamental upgrade in how industries approach process containment and safety in the most demanding operational contexts, reflecting a commitment to innovation and sustainability that defines industry leadership.

At the forefront of this material evolution are Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price, a sophisticated solution engineered to withstand the harshest conditions encountered in electrolytic processes. These cells leverage the exceptional chemical resistance of vinyl ester resins, combined with the structural strength of fiberglass reinforcement, fabricated through a monolithic casting process. This specific manufacturing technique ensures a seamless, homogeneous structure, eliminating potential weak points that might arise from joints or seams in fabricated assemblies. The result is an electrolytic cell that offers extraordinary resistance to a wide spectrum of acids, alkalis, and oxidizing agents, which are commonplace in electrolytic operations. Furthermore, the inherent electrical insulating properties of FRP prevent stray currents, enhancing the safety and efficiency of electrochemical reactions. These attributes directly contribute to reduced energy consumption, minimal product contamination, and a significantly prolonged operational lifespan compared to cells made from less resilient materials. The integration of advanced design principles with cutting-edge composite manufacturing techniques ensures that these electrolytic cells are not just components but strategic assets, delivering sustained performance and economic advantages in high-demand industrial applications where reliability is non-negotiable and performance critical to overall success.

The Advanced Manufacturing Process of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price

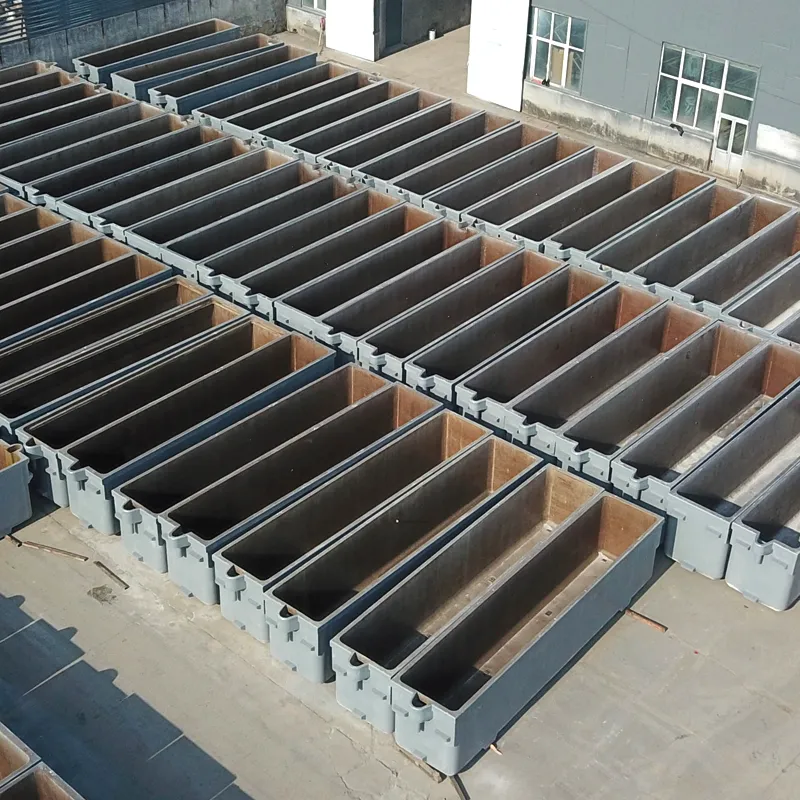

The production of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is a highly specialized and meticulously controlled process that ensures the integrity and superior performance of each unit. The core of this manufacturing lies in the monolithic casting technique, which stands distinct from traditional fabrication methods. It commences with the precise preparation of high-fidelity molds, which are often machined with CNC precision to guarantee exact dimensional accuracy and a flawless surface finish for the final product. These molds are critical for achieving the seamless structure characteristic of monolithic casting. Following mold preparation, a sophisticated resin mixture is prepared. This mixture consists primarily of high-grade vinyl ester resin, chosen for its excellent chemical resistance and mechanical properties, combined with specific catalysts, accelerators, and sometimes inert fillers to optimize curing characteristics and enhance specific physical attributes. The formulation of this resin blend is critical and often proprietary, designed to achieve optimal viscosity for casting while ensuring complete polymerization throughout the entire cell structure, preventing any localized weaknesses or porosity.

The actual casting phase for Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price involves the meticulous introduction of the prepared vinyl ester resin into the mold, often under vacuum or controlled pressure to eliminate air voids and ensure thorough saturation of the reinforcing fibers. Fiberglass reinforcement, typically in the form of chopped strand mat or woven rovings, is strategically placed within the mold to provide the necessary structural strength and rigidity. The resin is then allowed to cure under precisely controlled temperature and humidity conditions. This curing process can be extensive, often involving several stages, including an initial gelation, followed by a post-curing cycle at elevated temperatures to achieve maximum cross-linking and optimize the resin’s chemical and mechanical properties. The monolithic nature means the entire cell, including its internal compartments and structural elements, is formed as a single, contiguous piece, eliminating weak points associated with traditional assembly processes like welding or bonding multiple sections. This integrated design significantly enhances the cell's long-term integrity and resistance to chemical permeation, which is a critical factor in extending the service life of equipment operating in highly corrosive environments typical of electrolytic processes, directly contributing to its cost-effectiveness and durability.

Upon completion of the curing process, the Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price are carefully demolded, and subjected to a rigorous post-processing and quality control regimen. This stage includes precise trimming of excess material, surface finishing to ensure optimal flow dynamics and minimize potential for accumulation of process residues, and the integration of any necessary fittings or attachments, which are often themselves made from corrosion-resistant FRP or other compatible materials. Each cell undergoes a series of stringent inspections and tests to ensure compliance with international standards such as ISO and ANSI. These tests typically include visual inspections for surface defects, dimensional checks using precision gauges, non-destructive testing (NDT) methods like ultrasonic testing for internal flaws, and hydrostatic pressure testing to verify structural integrity and leak-proof performance under operational stresses. This comprehensive quality assurance protocol guarantees that every monolithic cell delivered meets the highest standards of reliability, performance, and safety, providing end-users with a product that delivers exceptional long-term value and operational peace of mind. The expected service life for these cells, when properly designed and installed, typically exceeds 20 years, even in highly aggressive chemical process environments, significantly surpassing the longevity of many alternative materials.

The applications for Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price span a variety of critical industries where corrosion resistance and electrical insulation are paramount. In the petrochemical sector, these cells are vital for processes involving strong acids and bases, such as the production of chlorine and caustic soda in chlor-alkali plants, or the refining of various chemicals where electrochemical reactions are fundamental. Within the metallurgy industry, specifically in hydrometallurgical operations, FRP electrolytic cells are extensively used for the electrowinning and electrorefining of non-ferrous metals like copper, zinc, nickel, and cobalt. The aggressive electrolyte solutions used in these processes, often containing high concentrations of sulfuric acid and various metal salts, necessitate materials that can withstand severe corrosive attacks over long periods, which is precisely where vinyl ester FRP excels. In water and wastewater treatment, certain specialized electrolytic processes for purification or disinfection also benefit immensely from the durability and chemical inertness of these cells, ensuring clean process streams and reducing the need for frequent equipment replacement.

A significant advantage of utilizing Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price in these demanding environments is their remarkable energy efficiency and enhanced safety profile. Unlike metallic cells which can conduct heat and electricity, leading to thermal losses and potential stray currents, FRP is an excellent insulator. This property significantly reduces heat loss from the electrolyte solution, leading to lower energy consumption for maintaining optimal operating temperatures. Furthermore, the non-conductive nature of FRP eliminates the risk of short circuits or stray currents, which can degrade electrodes, compromise process purity, and pose safety hazards to personnel. The smooth, monolithic interior surfaces of the cells also prevent the accumulation of deposits, which can impede electrolyte flow and reaction efficiency, thereby contributing to sustained optimal performance and reduced cleaning cycles. This combination of material stability, inherent safety features, and design optimization for process efficiency translates into substantial operational cost savings over the long term, making vinyl ester FRP electrolytic cells a financially sound and strategically beneficial choice for any industrial operation striving for peak performance and sustainable practices in the face of corrosive challenges.

Technical Specifications and Performance Metrics for Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price

Understanding the detailed technical specifications of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is crucial for engineers and procurement specialists seeking optimal solutions for their industrial processes. These cells are designed with precision, offering a balance of structural integrity, chemical resistance, and thermal stability. Typical dimensions can vary significantly based on specific client requirements and process volumes, ranging from compact laboratory-scale units to large industrial cells that can be several meters in length, width, and height. Standard wall thicknesses are typically designed to withstand anticipated hydrostatic and operational pressures, often ranging from 15mm to 30mm for the main body, with thicker sections at reinforced stress points or flange connections. The operating temperature range is a critical parameter, with vinyl ester resins generally performing exceptionally well from -30°C to +100°C, and specialized formulations capable of handling excursions up to +120°C. This wide thermal window allows for versatility across various electrochemical processes.

The robust nature of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is reflected in their impressive mechanical and chemical properties. Their tensile strength typically ranges from 120 MPa to 250 MPa, while flexural strength can be between 200 MPa and 350 MPa, showcasing their ability to withstand significant mechanical stresses without deformation. The specific gravity of these cells is remarkably low, usually around 1.8 to 2.0, making them considerably lighter than metallic alternatives, which simplifies installation and reduces structural support requirements. Chemical resistance is where vinyl ester truly shines; these cells exhibit excellent long-term resistance to a broad spectrum of aggressive chemicals, including concentrated sulfuric acid (up to 98% at moderate temperatures), hydrochloric acid, sodium hydroxide, and various chlorides, making them ideal for the highly corrosive electrolytes used in mineral processing and chemical manufacturing. The dielectric strength, typically exceeding 15 kV/mm, ensures superior electrical insulation, critical for preventing energy losses and ensuring operational safety in high-voltage electrolytic processes.

Here’s a summary of typical parameters for Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price, providing a clear technical overview for prospective industrial applications:

Real-World Applications and Client Success with Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price

The proven track record of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price in various demanding industrial settings underscores their reliability and performance advantages. In a major chlor-alkali plant located in the Middle East, our custom-designed FRP electrolytic cells replaced aging rubber-lined steel cells that were frequently failing due to chemical attack and galvanic corrosion. The transition resulted in a significant reduction in unscheduled downtime by an estimated 35% within the first year of operation, directly translating to enhanced production throughput and substantial savings on maintenance and replacement parts. The inherent electrical insulation of the vinyl ester composite also contributed to a measurable improvement in overall energy efficiency for the electrolysis process, validating the long-term operational benefits. This strategic upgrade allowed the plant to not only meet but exceed its production targets, solidifying the operational integrity of its critical processes and providing a significant competitive edge in a highly demanding global market.

Another compelling example of the successful deployment of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price comes from a prominent copper electrowinning facility in South America. Faced with an aggressive sulfuric acid electrolyte at elevated temperatures, the previous lead-lined concrete cells required continuous repair and posed environmental risks due to potential leaks. By implementing our monolithic FRP cells, the facility achieved superior containment and drastically extended the lifespan of their electrolytic infrastructure. Client feedback highlighted the ease of installation due to the lighter weight of FRP, coupled with the noticeable reduction in operational costs associated with corrosion-related failures and repairs. Over a five-year period, the client reported a return on investment significantly faster than anticipated, primarily driven by improved process stability and reduced material replacement costs. This case exemplifies how advanced composite solutions are not merely replacements but catalysts for operational excellence, enabling industries to achieve higher levels of efficiency, safety, and environmental stewardship, thereby securing a sustainable future for their critical production operations and establishing new benchmarks for industrial infrastructure.

Beyond these specific instances, our Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price are utilized in diverse applications, from zinc refining and nickel plating to specialized waste treatment processes. The common thread across all these successful deployments is the critical need for a material that can withstand extreme chemical aggression while maintaining structural integrity over decades. Our experience has shown that companies investing in these advanced FRP cells consistently report long-term operational benefits, including minimized maintenance requirements, enhanced process purity due to the inert nature of the material, and a safer working environment by containing hazardous electrolytes effectively. Furthermore, our commitment to providing tailored solutions ensures that each cell is designed to meet the precise specifications of the client’s process, integrating seamlessly into existing infrastructure and delivering optimal performance. These tangible results, backed by consistent client testimonials and performance data, reinforce the position of vinyl ester FRP monolithic casting as the premier choice for high-performance electrolytic cell solutions in the global industrial market.

Customization, Quality Assurance, and Customer Support for Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price

Recognizing that every industrial process presents unique challenges, we offer extensive customization options for our Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price. Our engineering team collaborates closely with clients to develop tailored solutions that precisely match their operational requirements, whether it involves unique dimensions, specific chemical resistance needs for unusual electrolytes, or integration with existing plant layouts. This bespoke approach ensures that the cells are not merely off-the-shelf components but fully optimized systems designed to maximize efficiency and longevity within a client's specific operational context. For instance, we can adjust wall thicknesses for varying pressure requirements, incorporate specialized nozzle configurations for specific piping systems, or design internal baffles and flow distributors to optimize electrolyte circulation and minimize dead zones within the cell. This level of customization, combined with the inherent design flexibility of FRP, allows for innovative solutions that would be difficult or impossible to achieve with traditional materials, ensuring seamless integration and superior performance for every application, no matter how complex the requirements.

Our commitment to quality is unwavering, underpinning the reliability and long-term performance of every Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price we deliver. Our manufacturing facilities adhere to stringent quality management systems, certified to ISO 9001 standards, ensuring consistency and excellence at every stage of production, from raw material inspection to final product testing. Each electrolytic cell undergoes comprehensive testing, including hydrostatic pressure tests to verify structural integrity and leak resistance, dimensional checks, and rigorous visual inspections for surface flaws or defects. We also perform material property testing on composite samples to confirm mechanical and chemical resistance properties meet or exceed design specifications. Furthermore, our decades of experience in the composite manufacturing industry mean that we bring unparalleled expertise to every project, guaranteeing products that not only meet but often surpass industry benchmarks for durability and performance. This extensive experience and meticulous quality control process provide our clients with the confidence that they are investing in a product of the highest caliber, built to deliver sustained, trouble-free operation even in the most aggressive industrial environments.

We back our products with comprehensive customer support and robust warranty provisions, reflecting our confidence in the enduring quality of our Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price. Our dedicated technical support team is available for pre-sales consultations, assisting clients in selecting the optimal design and material specifications for their unique applications. During and after installation, we provide comprehensive guidance and support to ensure smooth commissioning and efficient operation. Our standard warranty typically covers manufacturing defects for a period of up to five years, although extended warranties can be negotiated for specific projects, demonstrating our commitment to long-term client satisfaction. Regarding delivery, our streamlined production processes and efficient global logistics network enable us to provide competitive lead times, typically ranging from 8 to 12 weeks, depending on the complexity and scale of the order. This commitment to both product quality and exceptional service ensures that clients receive not just a product, but a complete solution backed by a reliable partner, leading to enhanced operational longevity and reduced total cost of ownership over the product's extensive lifespan.

Frequently Asked Questions (FAQ) about Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price

Q1: What are the primary advantages of Vinyl Ester Resin Monolithic Casting FRP Electrolytic Cells over traditional materials like steel or concrete?

The core advantages of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price are rooted in their superior material properties and manufacturing process. Unlike steel, even stainless steel or rubber-lined steel, FRP is inherently corrosion-resistant to a vast array of aggressive chemicals, including strong acids, alkalis, and salts common in electrolytic processes, eliminating concerns about rust, pitting, or liner delamination. This significantly extends the operational lifespan and reduces maintenance frequency. Compared to concrete cells, which are porous and susceptible to chemical attack and leakage over time, monolithic FRP cells offer a seamless, impermeable barrier, ensuring complete containment and preventing environmental contamination. Furthermore, FRP is an excellent electrical insulator, preventing stray currents that can degrade electrodes and reduce process efficiency, a common issue with metallic cells. The lightweight nature of FRP also simplifies transportation and installation, leading to reduced overall project costs, while its energy-efficient design helps optimize operational expenditures over the long term, contributing to a lower total cost of ownership that makes these cells a superior choice for long-term industrial applications requiring robust performance.

Q2: What is the typical lifespan of these electrolytic cells, and what factors influence it?

When properly designed, installed, and operated within their specified parameters, Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price are engineered for an exceptional service life, typically exceeding 20 years. Several factors contribute to this longevity. Firstly, the intrinsic chemical resistance of vinyl ester resin to the specific electrolyte being processed is paramount; choosing the correct resin formulation for the application ensures long-term material integrity. Secondly, adherence to the specified operating temperature and pressure limits is crucial, as exceeding these can accelerate material degradation. Regular, minimal maintenance, primarily focused on periodic visual inspections and ensuring the integrity of ancillary components, also plays a role. Environmental factors, such as UV exposure if installed outdoors without proper UV inhibitors, can also influence lifespan, though internal cells are generally protected. Our monolithic casting process further enhances durability by eliminating weak points like joints and seams, which are often failure points in traditionally fabricated vessels. This comprehensive approach to design, material selection, and manufacturing ensures that our FRP electrolytic cells provide extended, reliable service, minimizing the need for costly replacements and maintaining continuous operational efficiency for decades, providing significant value.

Q3: How do you ensure the "Best Price" for Vinyl Ester Resin Monolithic Casting FRP Electrolytic Cells without compromising quality?

Achieving the "Best Price" for Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price while upholding uncompromising quality is a cornerstone of our value proposition. This is accomplished through a multi-faceted approach. Firstly, our advanced manufacturing processes, including optimized monolithic casting techniques, minimize material waste and labor costs compared to more traditional, labor-intensive fabrication methods. We leverage economies of scale in raw material procurement, securing high-quality vinyl ester resins and fiberglass reinforcements at competitive prices through long-standing supplier relationships. Our extensive experience and expertise allow for highly efficient design and engineering, reducing prototyping cycles and optimizing material usage without sacrificing performance. Furthermore, by focusing on the total cost of ownership, including the significantly reduced maintenance, extended lifespan, and enhanced energy efficiency that our cells provide, the initial investment demonstrates superior long-term economic value compared to seemingly cheaper but less durable alternatives. This holistic approach ensures that our clients receive a product that offers both competitive upfront pricing and exceptional long-term value, making it a truly best-in-class investment for their industrial needs.

Conclusion: The Future of Electrolytic Processing

The relentless pursuit of efficiency, safety, and durability in industrial processes demands solutions that transcend the limitations of conventional materials. Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price represent a significant leap forward in this regard, offering an unparalleled combination of chemical resistance, structural integrity, electrical insulation, and extended service life. By integrating advanced material science with precision manufacturing techniques, these electrolytic cells provide a robust and economically viable alternative to traditional metallic or lined concrete systems. Their ability to withstand the harshest corrosive environments, minimize operational downtime, and contribute to energy savings makes them an indispensable asset for industries ranging from chemical manufacturing and hydrometallurgy to water treatment. Investing in these state-of-the-art FRP cells is not merely an equipment upgrade; it is a strategic decision that drives long-term operational excellence, reduces total cost of ownership, and enhances environmental sustainability, positioning businesses at the forefront of modern industrial practice and securing a competitive advantage in a demanding global market.

Our commitment to delivering superior quality, coupled with comprehensive customization options and dedicated customer support, ensures that our clients receive solutions perfectly tailored to their unique operational demands. We invite industry leaders and technical decision-makers to explore how our Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price can transform their electrolytic processes, leading to enhanced productivity, reduced maintenance burdens, and a safer, more sustainable operational footprint. By choosing our advanced FRP technology, you are investing in a future where your critical processes operate with unmatched reliability and efficiency, backed by decades of expertise and a proven track record of success in the most challenging industrial applications. This dedication to innovation and client-centric solutions positions us as a trusted partner in driving progress and achieving operational excellence across the chemical processing and metallurgical sectors, contributing significantly to a more resilient and sustainable industrial landscape globally.

References

- Composites Science and Technology Journal. "Advances in Vinyl Ester Resins for Corrosion-Resistant Applications."

- Journal of Applied Electrochemistry. "Performance Evaluation of FRP Materials in Electrowinning Cells."

- Polymer Composites Journal. "Monolithic Casting Techniques for High-Performance Fiber-Reinforced Polymers."

- Corrosion Science. "Long-term Durability of FRP in Aggressive Chemical Environments."

- Materials Performance Magazine. "Innovations in Corrosion Protection for Industrial Electrolytic Processes."