GRP Tank Applications in Industrial Processes

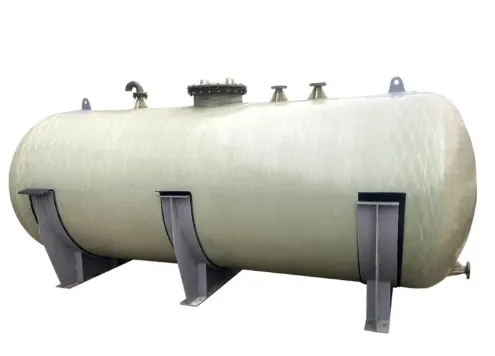

As Hebei Aoliande Chemical Equipment Co., Ltd., a leading wholesaler in the industrial equipment sector, we are well - aware of the extensive and diverse applications of GRP tanks in various industrial processes. GRP tanks, along with their counterparts FRP tanks, have become indispensable assets in industries that rely on the safe storage and handling of materials, especially in the context of chemical tank usage. Our company is committed to providing high - quality GRP tanks that meet the specific demands of different industrial applications, ensuring reliability, durability, and cost - effectiveness for our customers.

GRP Tanks as Ideal Solutions for Chemical Storage in Industrial Settings

In industrial settings where the storage of chemicals is a critical aspect, GRP tanks emerge as ideal solutions. Their exceptional chemical resistance makes them suitable for housing a wide range of corrosive substances, ensuring the integrity of the stored chemicals and preventing leakage. Compared to traditional chemical tank materials, GRP tanks from Hebei Aoliande Chemical Equipment Co., Ltd. offer better protection against chemical degradation, reducing the risk of environmental contamination and ensuring the safety of personnel. This makes them a preferred choice for industries dealing with aggressive chemicals.

The Role of GRP Tanks in Wastewater Treatment Industrial Processes

GRP tanks play a crucial role in wastewater treatment industrial processes. They are used for storing raw wastewater, holding treated water, and containing chemicals used in the treatment process. The non - metallic nature of GRP tanks prevents rust and corrosion, which is essential in the often - harsh environment of wastewater treatment plants. Hebei Aoliande Chemical Equipment Co., Ltd.'s GRP tanks are designed to withstand the varying pH levels and chemical compositions found in wastewater, ensuring long - term functionality and contributing to the overall efficiency of the treatment process.

GRP Tanks in the Food and Beverage Industry for Safe Storage

In the food and beverage industry, where hygiene and safety are of utmost importance, GRP tanks provide a reliable storage solution. These tanks are non - toxic and do not react with food products, ensuring that the stored items remain safe and uncontaminated. Unlike some traditional chemical tank materials that might pose a risk of leaching harmful substances, GRP tanks from Hebei Aoliande Chemical Equipment Co., Ltd. meet strict food - grade standards. Their smooth surfaces also make them easy to clean, further enhancing their suitability for food and beverage storage applications.

Advantages of GRP Tanks Over FRP Tanks in Certain Industrial Applications

While both GRP tanks and FRP tanks have their merits, in certain industrial applications, GRP tanks offer distinct advantages. GRP tanks typically have a higher glass content, which contributes to greater strength and stiffness. This makes them more suitable for applications that require the storage of heavy liquids or where structural integrity under high pressure is crucial. Hebei Aoliande Chemical Equipment Co., Ltd. leverages these inherent properties of GRP tanks to provide customers with solutions that are optimized for their specific industrial needs, outperforming FRP tanks in such demanding scenarios.

GRP Tank FAQs

Why are GRP tanks preferred for chemical storage over other types of chemical tanks?

GRP tanks are preferred for chemical storage over other types of chemical tanks due to their excellent chemical resistance. Hebei Aoliande Chemical Equipment Co., Ltd.'s GRP tanks can withstand the corrosive effects of a wide range of chemicals, reducing the risk of leaks and material degradation. Their non - metallic composition also eliminates the problem of rust, ensuring the safety of the stored chemicals and the surrounding environment, making them a reliable choice for industrial chemical storage.

How do GRP tanks contribute to the efficiency of wastewater treatment processes?

In wastewater treatment processes, GRP tanks from Hebei Aoliande Chemical Equipment Co., Ltd. contribute significantly to efficiency. They can safely store raw wastewater without being affected by its often - aggressive chemical composition. When used to hold treatment chemicals or treated water, their durability and resistance to corrosion ensure consistent performance. Their ability to withstand varying pH levels and chemical reactions helps maintain the integrity of the treatment process, enabling smooth operation of wastewater treatment plants.

What makes GRP tanks suitable for the food and beverage industry?

GRP tanks are suitable for the food and beverage industry because they meet strict safety and hygiene standards. Hebei Aoliande Chemical Equipment Co., Ltd.'s GRP tanks are non - toxic and do not contaminate food products. Their smooth surfaces are easy to clean, preventing the buildup of bacteria and other contaminants. Unlike some materials used in traditional chemical tanks, GRP does not leach harmful substances into the stored food or beverages, ensuring product safety and quality, which is essential in this industry.

In what industrial scenarios do GRP tanks outperform FRP tanks?

GRP tanks outperform FRP tanks in industrial scenarios where high strength and stiffness are required. For example, when storing heavy liquids or in applications involving high internal pressure, the higher glass content in GRP tanks gives them greater structural integrity. Hebei Aoliande Chemical Equipment Co., Ltd. designs GRP tanks to capitalize on these properties, making them the better choice for industries that need to store dense materials or operate under challenging mechanical conditions.

How does Hebei Aoliande Chemical Equipment Co., Ltd. ensure customized GRP tank solutions meet industrial needs?

Hebei Aoliande Chemical Equipment Co., Ltd. ensures customized GRP tank solutions meet industrial needs through a comprehensive approach. Our experts first conduct in - depth consultations with customers to understand their specific requirements, such as the nature of stored materials, environmental conditions, and space limitations. Then, we use advanced design and manufacturing techniques to create tanks that are precisely tailored to these needs. Throughout the process, we maintain strict quality control to ensure the final GRP tank is a perfect fit for the customer's industrial application.