Filament Winding Machine: Key Features and Functions

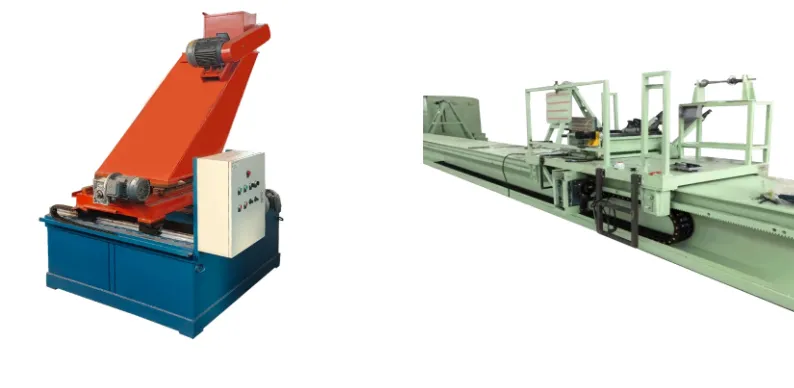

The filament winding machine represents a cornerstone technology in composite manufacturing, enabling the precise fabrication of high-strength cylindrical and spherical structures. These sophisticated machines, also known as filament winders, have revolutionized industries ranging from aerospace to energy storage by automating the process of wrapping continuous fibers around a rotating mandrel. Understanding the capabilities of a filament winding machine, along with factors affecting filament winding machine price, is essential for manufacturers seeking to enhance their production of pressure vessels, pipes, and other composite components. This comprehensive guide explores the technical specifications, operational principles, and economic considerations that define modern filament winding technology.

Operational Principles Behind Filament Winder Technology

The fundamental operation of a filament winder follows precise geometric algorithms to achieve optimal fiber placement. As the mandrel rotates, the carriage system moves along its length, laying fibers in predetermined patterns that maximize structural integrity. Contemporary filament winding machine controllers utilize sophisticated CAD/CAM software that translates engineering specifications into machine movements, allowing for complex winding paths including helical, polar, and hoop configurations. The precision of these systems directly impacts product quality - modern filament winders can maintain fiber placement accuracy within ±0.1mm, critical for aerospace and defense applications. Temperature-controlled resin baths in advanced filament winding machine models ensure consistent viscosity for uniform fiber impregnation, while programmable tensioners adapt to different material combinations. These operational refinements contribute to the wide variance in filament winding machine price points across different capability tiers.

Factors Influencing Filament Winding Machine Price

The filament winding machine price spectrum reflects substantial variation based on technical specifications and production capacity. Entry-level filament winder models designed for educational or prototyping purposes may start around $50,000, while industrial-scale machines with advanced automation can exceed $500,000. Key determinants of filament winding machine price include the number of controlled axes (with 4-axis systems commanding premium pricing), maximum mandrel diameter capacity, and precision levels of motion control systems. Additional cost factors encompass the inclusion of ancillary systems like automated resin mixing, in-process inspection technologies, and post-curing capabilities. The filament winding machine price also varies significantly based on production throughput - high-volume industrial systems feature faster carriage speeds (up to 1 m/s) and rapid mandrel change systems that justify their higher capital costs through increased operational efficiency. Manufacturers must carefully evaluate these technical parameters against their production requirements when considering filament winding machine investments.

Advanced Features in Modern Filament Winder Systems

Recent technological advancements have dramatically expanded the capabilities of filament winder equipment. The latest generation filament winding machine models incorporate artificial intelligence for adaptive process control, automatically adjusting winding parameters based on real-time sensor feedback. Robotic fiber placement arms have begun appearing in premium filament winder configurations, enabling complex geodesic patterns impossible with conventional systems. Many high-end filament winding machine units now offer hybrid manufacturing capabilities, combining traditional winding with additive manufacturing processes for integrated component production. These innovations naturally affect filament winding machine price structures but provide unparalleled manufacturing flexibility. Other notable advancements include self-cleaning resin systems that minimize material waste, and IoT-enabled predictive maintenance features that reduce downtime - both becoming standard expectations in contemporary filament winding machine offerings across price points.

Industry Applications Driving Filament Winding Machine Demand

The versatility of filament winding machine technology supports diverse industrial applications, each with unique technical requirements. Aerospace manufacturers utilize precision filament winders to produce lightweight composite rocket motor cases and aircraft components that demand exacting fiber placement tolerances. The energy sector employs filament winding machine systems for manufacturing high-pressure hydrogen storage tanks and wind turbine blades, where structural integrity directly impacts safety. Medical device companies leverage compact filament winder models to create MRI components and prosthetics requiring biocompatible composites. These varied applications explain the broad filament winding machine price range available in today's market, with specialized systems for niche applications often commanding premium pricing due to their customized engineering solutions and low production volumes.

Filament Winding Machine FAQs

What Determines the Production Speed of a Filament Winder?

The operational speed of a filament winder depends primarily on carriage movement velocity, mandrel rotation rates, and the complexity of winding patterns, with industrial systems achieving significantly faster cycle times than laboratory models.

How Does Filament Winding Machine Price Correlate with Precision?

Higher filament winding machine price points typically reflect improved precision capabilities, with premium systems offering sub-millimeter fiber placement accuracy critical for aerospace and defense applications.

Can a Single Filament Winding Machine Handle Different Mandrel Sizes?

Most filament winder systems accommodate various mandrel diameters within their design range, though extreme size variations may require customized machine configurations.

What Maintenance Does a Filament Winding Machine Require?

Routine filament winding machine maintenance includes resin system cleaning, motion component lubrication, and regular calibration checks to maintain winding precision.

How Has Automation Impacted Filament Winder Operations?

Modern filament winder systems incorporate advanced automation for material handling, quality control, and data collection, significantly reducing labor requirements while improving consistency.

Revolutionize Your Composite Manufacturing Today,From basic filament winder models to fully automated production systems, the modern filament winding machine market offers solutions for every manufacturing need and budget. Understanding the relationship between technical capabilities and filament winding machine price ensures informed investment decisions that align with your production requirements. Whether you're establishing new composite manufacturing capacity or upgrading existing infrastructure, our comprehensive range of filament winding machine solutions delivers unmatched performance and reliability. Visit our website to explore our full product lineup and discover how advanced filament winding technology can transform your manufacturing operations. Our expert team stands ready to help you select the perfect system that balances performance, precision, and filament winding machine price considerations for your specific application needs.