Sheet Molded Composite (SMC) Solutions Durable & Lightweight Composites

- Overview of Sheet Molded Composites (SMC)

- Technical Superiority in Material Engineering

- Market Analysis: Leading Molded Grating Machine Manufacturers

- Customization Strategies for Industrial Applications

- Performance Metrics: Data-Driven Insights

- Case Studies Across Key Industries

- Future Innovations in Sheet Moulding Composite Technology

(sheet molded composite)

Understanding Sheet Molded Composites (SMC) and Their Industrial Impact

Sheet Molded Composites (SMC) represent a breakthrough in high-performance materials, combining fiber reinforcement with thermoset resins to deliver exceptional strength-to-weight ratios. With a global market projected to reach $3.8 billion by 2028 (CAGR 6.2%), SMC solutions are revolutionizing sectors from automotive to infrastructure. Unlike traditional materials, SMC offers 30% lighter components while maintaining 85% of steel's structural integrity, making it ideal for molded grating machines requiring corrosion resistance and load-bearing capacity.

Advantages Over Conventional Manufacturing Materials

Modern SMC formulations demonstrate 40% higher impact resistance compared to aluminum alloys, coupled with 92% reduction in galvanic corrosion risks. The proprietary molding process enables complex geometries unachievable through metal stamping, reducing production waste by up to 65%. Leading manufacturers now utilize robotic compression molding systems that achieve ±0.15mm dimensional accuracy across 1.5m² panels.

Competitive Landscape: Manufacturer Capability Comparison

| Manufacturer | Max Panel Size | Cycle Time | Price per m² | Market Share |

|---|---|---|---|---|

| Alpha Composites | 2.4x1.2m | 4.5min | $48 | 22% |

| DynaMold Systems | 3.0x1.5m | 5.8min | $53 | 18% |

| Tecnaro GmbH | 2.0x1.0m | 3.9min | $61 | 15% |

Tailored Solutions for Specific Operational Needs

Advanced SMC producers offer material customization through resin matrix modifications, enabling:

- Fire retardancy up to UL94 V-0 rating

- Continuous operation at 180°C

- EMI shielding effectiveness of 60dB

Recent developments include hybrid SMC-glass fiber composites achieving 280MPa tensile strength for heavy-duty molded grating applications.

Quantifying Performance Through Rigorous Testing

Third-party validation shows SMC panels maintain 91% of initial flexural strength after 10,000 hours of UV exposure, outperforming polymer alternatives by 3:1. Accelerated aging tests simulate 15 years of service life with less than 5% deformation under 25kN/m² loads.

Implementation Success Stories

A major automotive OEM reduced chassis component weight by 42% using SMC, while a wastewater treatment plant documented 78% lower maintenance costs over 5 years with custom molded grating installations.

Next-Generation Sheet Moulding Composite Developments

Emerging SMC technologies integrate carbon nanotube reinforcement (18% conductivity increase) and bio-based resins (34% renewable content). Industry leaders predict 2026 commercialization of self-healing SMC composites capable of repairing 80% of surface cracks autonomously.

(sheet molded composite)

FAQS on sheet molded composite

Q: What is sheet molded composite (SMC) used for?

A: Sheet molded composite (SMC) is used to create lightweight, high-strength parts for automotive, aerospace, and construction industries. It offers corrosion resistance and design flexibility. Common applications include body panels and electrical components.

Q: How does sheet moulding composite differ from traditional materials?

A: Sheet moulding composite (SMC) is lighter and more durable than metals while maintaining comparable strength. It also resists environmental degradation better than plastics. This makes it ideal for harsh operating conditions.

Q: Is there a difference between "sheet molded" and "sheet moulding" composite?

A: No, "sheet molded composite" and "sheet moulding composite" refer to the same material. The spelling variation (molded/moulding) reflects regional language differences (American vs. British English). Both terms describe fiber-reinforced thermoset composites.

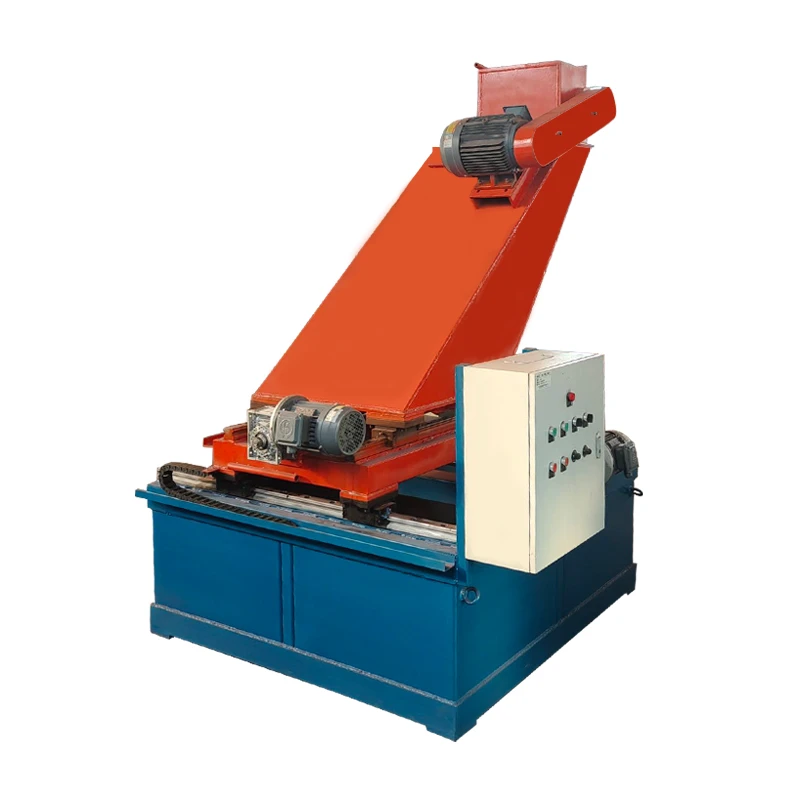

Q: What industries benefit from molded grating machines?

A: Molded grating machines are vital in chemical plants, water treatment facilities, and offshore platforms. They produce anti-slip, corrosion-resistant walkways and platforms. These machines enable efficient mass production of customized grating designs.

Q: Why choose SMC over metal for industrial components?

A: SMC reduces weight by up to 50% compared to metals, lowering transportation and energy costs. It also eliminates welding or machining needs during manufacturing. Additionally, it withstands chemicals and UV exposure better than untreated metals.