Advanced FRP Rebar Machine for Efficient GFRP Rebar Production

Understanding the Emergence of Advanced Composite Rebar Technology

The global construction and infrastructure sectors are continually seeking innovative materials that offer superior performance, longevity, and sustainability compared to traditional options. In this context, Fiber Reinforced Polymer (FRP) rebar, particularly Glass Fiber Reinforced Polymer (GFRP) rebar, has emerged as a transformative solution. Unlike conventional steel reinforcement, FRP rebar offers inherent corrosion resistance, high tensile strength-to-weight ratio, and electromagnetic transparency, making it ideal for applications in harsh environments or specialized structures. This shift is driven by increasing demands for infrastructure resilience, reduced maintenance costs, and a longer design life for critical assets. The core technology enabling the efficient and consistent production of these advanced materials is the frp rebar machine, a sophisticated piece of industrial equipment designed for high-volume, precision manufacturing. Its development signifies a pivotal advancement in material science and engineering, providing a robust answer to challenges like steel corrosion in coastal areas, de-icing salt exposure in bridges, and electromagnetic interference in sensitive medical or research facilities. As the market embraces these superior composites, understanding the capabilities of the machinery behind their production becomes paramount for investors, engineers, and project developers looking to integrate future-proof solutions into their portfolios. The efficiency and reliability of these machines directly impact the quality and cost-effectiveness of the final FRP rebar product, influencing its widespread adoption in various critical infrastructure projects globally. This introduction sets the stage for a deeper dive into the technological prowess of these manufacturing lines and their significant impact on modern construction.

The escalating demand for durable, non-corrosive reinforcement materials has spurred rapid innovation within the composite manufacturing industry. Traditional steel rebar, while robust, is susceptible to rust and degradation, leading to significant repair and replacement costs over the lifespan of concrete structures, especially in environments exposed to chlorides or aggressive chemicals. This vulnerability often necessitates extensive maintenance schedules and can compromise structural integrity over time. In response, composite alternatives such as GFRP rebar have gained substantial traction, offering a compelling array of advantages including unparalleled resistance to corrosion, high electrical resistivity, and lightweight properties that simplify transportation and handling. The specialized equipment responsible for producing these advanced materials, often referred to as a frp rebar machine or a gfrp rebar machine, represents the cutting edge of pultrusion technology. These machines are engineered to precisely impregnate continuous glass fiber rovings with thermosetting resins, cure them under controlled conditions, and form them into specific rebar profiles. This intricate process ensures the consistent quality, dimensional accuracy, and mechanical properties essential for high-performance applications. The industry's current trajectory indicates a strong shift towards these composite solutions, driven by their lower life-cycle costs and enhanced performance envelope. The capability of these manufacturing lines to produce varying diameters and profiles of FRP rebar also provides significant flexibility for diverse project requirements, further accelerating their adoption across different engineering disciplines, from marine structures to MRI rooms.

Detailed Process Flow of FRP Rebar Manufacturing

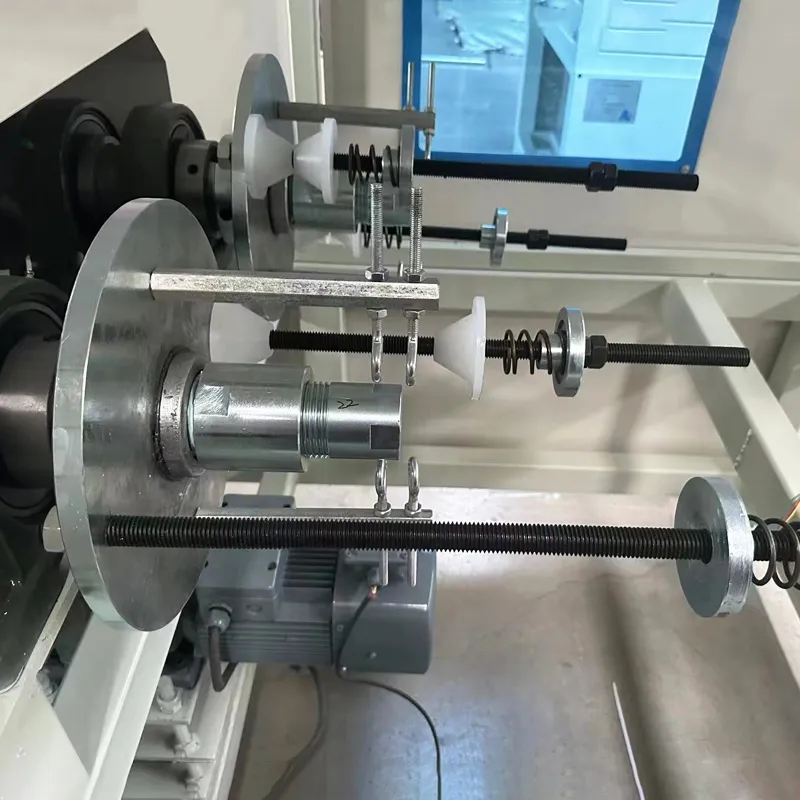

The production of FRP rebar using a specialized frp rebar machine is a highly automated and precise process, predominantly relying on the pultrusion technique. This method involves pulling continuous fibers, such as glass fiber rovings (for GFRP), through a resin bath, where they are thoroughly impregnated with a thermosetting polymer resin matrix, typically vinylester or polyester. The saturation ensures complete encapsulation of the fibers, which are the primary load-bearing components of the composite. Following the resin impregnation, the saturated fibers are guided through a pre-forming guide that shapes them into the desired rebar profile and removes excess resin, ensuring uniform diameter and surface finish. This pre-forming stage is critical for maintaining dimensional accuracy and preparing the material for the subsequent curing phase. The fibers then enter a heated die, where the resin undergoes polymerization, transforming from a liquid to a solid state. This curing process, often facilitated by precise temperature control within the die, is exothermic and requires careful management to prevent defects. The speed of pultrusion and the temperature profile of the die are meticulously calibrated by the gfrp rebar machine to achieve optimal cure, ensuring the rebar achieves its designed mechanical properties, including high tensile strength and stiffness. The manufacturing process for FRP rebar is a continuous operation, signifying high efficiency and production capacity once the line is set up and calibrated.

Post-curing, the rigid FRP rebar exits the die and proceeds to the cooling and pulling section. The pulling mechanism, often a caterpillar-type puller, continuously draws the rebar through the entire pultrusion line at a controlled speed. This section also often incorporates a sand-coating unit or a spiral-winding unit to create an outer rough surface, which is essential for ensuring superior bond strength with concrete. The surface texture enhances the mechanical interlocking between the rebar and the surrounding concrete, preventing slippage and ensuring effective stress transfer. Quality control is integrated throughout the entire production cycle, starting from the raw material inspection—verifying the quality of glass fibers, resins, and additives—through to in-line monitoring during the pultrusion process. Critical parameters such as resin-to-fiber ratio, curing temperature, pulling speed, and final dimensional tolerances are continuously monitored by the frp rebar machine's sophisticated control systems. Final product inspection includes rigorous testing of tensile strength, shear strength, bond strength, and corrosion resistance, adhering to international standards such as ACI 440.1R, ASTM D7957, ISO 10406, and CSA S806. These comprehensive quality checks ensure that each batch of FRP rebar meets the stringent performance requirements for its intended application, guaranteeing a product with an exceptional service life, often exceeding 100 years in challenging environments.

The final stage of the FRP rebar manufacturing process involves cutting the continuous profile into specified lengths, packaging, and preparing for dispatch. This cutting unit is typically integrated into the frp rebar machine line, allowing for automated and precise cuts based on customer orders. The flexibility of these production lines allows for the manufacture of rebar in various diameters, from small sizes for residential applications to large diameters for heavy-duty civil engineering projects. The material selection—primarily E-glass fibers for general applications, or ECR-glass for enhanced corrosion resistance—along with the specific resin chemistry and additives, dictate the final performance characteristics and suitability for diverse industries. Applicable industries benefitting from FRP rebar include petrochemical plants, where resistance to aggressive chemicals is paramount; marine and coastal structures, due to their imperviousness to salt water corrosion; wastewater treatment facilities; infrastructure projects such as bridges, roads, and tunnels, especially those exposed to de-icing salts; and specialized applications like MRI suites in hospitals, where non-magnetic properties are essential. The intrinsic advantages of FRP rebar, such as its energy efficiency (lower embodied energy compared to steel in some contexts), superior corrosion resistance, and extended service life without significant maintenance, position it as a critical component in sustainable and resilient infrastructure development.

Technical Specifications and Performance Metrics of FRP Rebar Machines

A state-of-the-art frp rebar machine is engineered to meet rigorous production demands, ensuring precision, efficiency, and consistent output quality. Key technical specifications include the machine's pulling force, which dictates the maximum rebar diameter and production speed it can handle; heating zones and temperature control accuracy, crucial for optimal resin curing; and the control system's sophistication, often featuring PLC (Programmable Logic Controller) for automated operation, fault detection, and real-time parameter adjustments. The core of its performance lies in its ability to maintain precise resin impregnation and fiber alignment, which directly translates to the finished product's structural integrity. Typically, these machines can produce rebar ranging from 4mm to 32mm in diameter, with some advanced models capable of larger custom sizes. Production speeds vary significantly based on rebar diameter and desired cure rate, ranging from 0.5 to 2.0 meters per minute per strand, with multi-strand capabilities dramatically increasing total output. Energy efficiency is also a crucial design consideration, with modern machines utilizing optimized heating elements and insulation to minimize power consumption. Understanding these parameters is essential for any enterprise looking to invest in a gfrp rebar machine, as they directly impact operational costs and return on investment. The design also incorporates robust safety features, including emergency stops, overload protection, and interlocks, ensuring a safe working environment for operators in industrial settings.

The performance metrics of the produced FRP rebar are directly influenced by the precision and control offered by the frp rebar machine. One critical parameter is the ultimate tensile strength, which for GFRP rebar can exceed 900 MPa, significantly higher than steel rebar on a strength-to-weight basis. Elastic modulus, typically around 40-50 GPa, is another vital characteristic, indicating the material's stiffness. Although lower than steel, this property is accounted for in design codes like ACI 440.1R, which provide specific guidelines for FRP concrete reinforcement. The corrosion resistance of FRP rebar is a defining advantage; it does not rust or spall concrete, eliminating issues like concrete cracking and delamination caused by steel corrosion. Furthermore, FRP rebar is non-conductive and non-magnetic, making it indispensable for structures where electromagnetic transparency is required, such as in hospitals for MRI scanners, power generation facilities, or research laboratories. The long-term durability of the rebar is also paramount; testing validates that FRP rebar maintains its mechanical properties over extended periods, even under aggressive chemical exposure or fluctuating temperatures. This inherent durability translates to extended service life for structures, dramatically reducing maintenance costs and contributing to lower life-cycle costs. The machinery ensures consistent fiber volume fraction and resin cure, which are fundamental to achieving these superior material properties in the final FRP rebar product.

Typical FRP Rebar Machine Production Line Parameters

Diverse Application Scenarios and Key Technical Advantages

The versatility and superior performance characteristics of FRP rebar, made possible by advanced frp rebar machine technology, allow it to be deployed across a wide spectrum of demanding engineering applications. In marine and coastal infrastructure, where traditional steel is highly vulnerable to chloride-induced corrosion, FRP rebar provides an impervious solution for seawalls, piers, jetties, and breakwaters, dramatically extending their operational lifespan and reducing costly maintenance cycles. Similarly, in chemical processing plants and wastewater treatment facilities, its resistance to various aggressive chemicals, including acids and alkalis, makes it an ideal reinforcement for tanks, containment structures, and pipelines. Beyond corrosive environments, FRP rebar's non-magnetic and electrically non-conductive properties are invaluable in highly specialized fields. It is the material of choice for concrete structures in medical facilities housing MRI machines, ensuring that the powerful magnetic fields are not distorted, and for electrical substations or research laboratories where electromagnetic interference must be minimized. The lightweight nature of FRP rebar also contributes to logistical efficiencies, lowering transportation costs and simplifying on-site handling, leading to faster construction timelines.

Another significant advantage of employing FRP rebar is its extended service life, which directly translates to substantial economic benefits over the life cycle of a project. While the initial material cost of FRP rebar might be higher than steel, the elimination of corrosion-related repairs, concrete spalling, and premature structural deterioration results in a far lower total cost of ownership. This long-term value proposition is particularly appealing for public infrastructure projects with projected lifespans of 50-100 years or more. Furthermore, the low thermal conductivity of FRP rebar contributes to energy efficiency in buildings by reducing thermal bridging, which can be an issue with highly conductive steel reinforcement. This characteristic enhances the thermal performance of insulated concrete structures, contributing to lower heating and cooling costs over the building's occupancy. From a sustainability perspective, while the embodied energy of FRP rebar varies by manufacturing process and resin type, its exceptional durability and minimal maintenance requirements significantly reduce the overall environmental footprint compared to alternatives that necessitate frequent replacement or extensive repair due. The precision and consistency offered by a modern frp rebar machine are foundational to realizing these technical advantages in real-world applications, ensuring that the produced rebar performs as specified in the most demanding environments.

Manufacturer Comparison and Custom Solutions for FRP Rebar Machines

When selecting an frp rebar machine, potential buyers often face a complex decision given the varying levels of technology, automation, and support offered by different manufacturers. Leading manufacturers in the composite machinery sector differentiate themselves through several key aspects, including the precision of their pultrusion dies, the robustness of their pulling systems, the sophistication of their control software, and their after-sales service and technical support. Some manufacturers specialize in high-speed, multi-strand machines for large-scale production facilities, while others focus on modular, adaptable systems suitable for diverse production needs or smaller batch runs. The quality of components used, such as heating elements, sensors, and PLC units, is also a critical differentiator, directly impacting machine longevity and operational reliability. Furthermore, reputable manufacturers often hold international certifications such as ISO 9001 for quality management, demonstrating a commitment to consistent manufacturing practices and product excellence. Engaging with a manufacturer who can demonstrate a proven track record of successful installations and provide comprehensive training programs for operators is crucial for maximizing the return on investment. The global market for gfrp rebar machine technology is dynamic, with ongoing innovations in automation, energy efficiency, and material handling systems continually improving the capabilities of these production lines.

Comparative Overview of FRP Rebar Machine Manufacturers (Illustrative)

Beyond standard offerings, many leading manufacturers provide comprehensive custom solutions for the frp rebar machine. This often involves tailoring the machine's dimensions, pulling force, number of strands, and heating configurations to meet specific production goals or accommodate unique material formulations. For instance, a client might require a machine optimized for producing large-diameter rebar for bridge deck reinforcement, or one configured for specialized resins designed for extreme temperature environments. Customization also extends to integrating the pultrusion line with upstream processes, such as fiber creels for various roving types, and downstream operations, including advanced cutting systems, automated bundling, and packaging solutions. Some manufacturers also offer complete turnkey solutions, from initial site assessment and factory layout design to installation, commissioning, and ongoing operational support. This includes training for operational staff and maintenance teams, ensuring that the client's team is fully proficient in running and maintaining the advanced equipment. Such end-to-end service, coupled with a deep understanding of composite materials and engineering, positions a manufacturer as a true partner in a client's composite rebar production venture, fostering long-term collaborative relationships and optimizing the entire manufacturing workflow for efficiency and quality.

Application Cases and Client Testimonials

The proven efficacy of FRP rebar in diverse real-world projects serves as the ultimate testament to the capabilities of the frp rebar machine and the materials it produces. A notable case study involves a major bridge deck replacement project in a coastal region, where chloride-induced corrosion was a recurring issue with steel-reinforced concrete. By specifying GFRP rebar produced by a high-capacity gfrp rebar machine, the project engineers ensured a projected service life exceeding 100 years, significantly reducing future maintenance costs and environmental impact associated with repairs. Another compelling example is its use in the construction of foundations and slabs for an advanced research facility housing sensitive magnetic resonance equipment. The non-magnetic properties of the FRP rebar ensured zero interference with the precision instruments, a requirement impossible to meet with steel reinforcement. Furthermore, in municipal wastewater treatment plants, FRP rebar has been successfully deployed in aeration basins and clarifiers, resisting the aggressive chemical environment that would rapidly degrade conventional steel, thereby enhancing the longevity and operational reliability of these critical public utilities. These real-world applications underscore the transformative potential of FRP rebar, validating its technical advantages and cost-effectiveness in challenging scenarios.

Client feedback consistently highlights the reliability and operational efficiency of modern frp rebar machine installations. A client in the Middle East, operating a large-scale infrastructure development company, praised the robust construction and automated controls of their recently installed multi-strand pultrusion line. "The consistency of output and the minimal downtime have far exceeded our expectations," stated their Head of Operations. "This machine has enabled us to meet the escalating demand for corrosion-resistant rebar in our coastal projects, significantly improving project timelines and overall structural durability. The ability to produce various rebar sizes on a single line has also provided unparalleled manufacturing flexibility." Another testimonial from a European precast concrete manufacturer emphasized the low maintenance requirements and energy efficiency. "Our new frp rebar machine has not only reduced our operational costs but also aligns with our corporate sustainability goals due to its efficient energy consumption and the long life of the rebar it produces. The technical support provided by the manufacturer was exceptional, ensuring a smooth transition to FRP rebar production." These positive experiences from diverse geographic regions and industry sectors reinforce the value proposition of investing in high-quality FRP rebar manufacturing equipment, demonstrating its crucial role in driving innovation and efficiency across the global construction industry.

Ensuring Trust: Quality Assurance, Delivery, and Customer Support

Establishing and maintaining trust is paramount in the B2B sector, especially for complex machinery like an frp rebar machine. Reputable manufacturers achieve this through rigorous quality assurance protocols that span the entire product lifecycle, from initial design and component sourcing to manufacturing, testing, and after-sales support. Compliance with international standards such as ISO 9001 for quality management systems is a fundamental indicator of a manufacturer's commitment to excellence and consistent production quality. Before dispatch, each gfrp rebar machine undergoes extensive factory acceptance testing (FAT) to verify its operational parameters, safety features, and output capabilities, often in the presence of the client's technical team. This ensures that the machine meets all specified performance criteria before shipment. Transparency in the supply chain, including the origin and quality of critical components, also builds confidence. Furthermore, a clear and reliable delivery schedule is crucial, with manufacturers providing detailed project timelines from order placement to installation and commissioning. Any potential delays are communicated proactively, along with mitigation strategies, ensuring that clients can plan their production schedules effectively. This systematic approach to quality and project management is essential for long-term client satisfaction and operational success.

Beyond the initial sale and delivery, comprehensive customer support is a cornerstone of trustworthiness for an frp rebar machine provider. This includes a robust warranty policy, typically covering mechanical and electrical components for a specified period (e.g., 1-2 years), demonstrating the manufacturer's confidence in their product's durability. Prompt technical support, often available remotely via advanced diagnostic systems, minimizes downtime and facilitates rapid troubleshooting of operational issues. Many leading manufacturers offer 24/7 technical hotlines or online support portals, recognizing that production lines operate around the clock in many regions. On-site technical assistance for complex installations, training, or major repairs is also a standard offering. Furthermore, a commitment to providing genuine spare parts, with clear pricing and availability, ensures the long-term operational viability of the machinery. Regular software updates for the PLC and HMI systems can enhance machine performance, introduce new features, and improve efficiency over time. This holistic approach to customer support ensures that clients receive continuous value from their investment, fostering enduring partnerships built on reliability, responsiveness, and a shared commitment to achieving optimal production outcomes.

Frequently Asked Questions (FAQ) about FRP Rebar Machines

- Q1: What is the typical lead time for an FRP Rebar Machine?

- A1: The lead time for a standard frp rebar machine can range from 8 to 16 weeks, depending on the manufacturer's current production schedule, machine configuration (number of strands, level of automation), and customization requirements. For highly customized or large-scale multi-strand systems, the lead time may extend up to 20-24 weeks. This includes design, manufacturing, assembly, factory acceptance testing, and preparation for shipment. Clients are always provided with a detailed project timeline upon order confirmation.

- Q2: What kind of space requirements are there for a typical FRP Rebar production line?

- A2: A typical FRP Rebar production line requires a significant linear space due to the pultrusion process. For a standard machine producing rebar up to 32mm, a footprint of approximately 20-30 meters in length and 2.5-4 meters in width is usually needed. This accounts for the creel, resin impregnation bath, curing oven/die, pulling unit, and cutting station. Adequate space for material handling, raw material storage (fiber rovings, resin drums), and finished product storage should also be factored in, usually increasing the total required area significantly. Manufacturers typically provide detailed layout drawings for factory planning.

- Q3: What are the primary raw materials required for FRP Rebar production?

- A3: The primary raw materials for producing FRP rebar using a frp rebar machine are continuous glass fiber rovings (e.g., E-glass or ECR-glass, depending on desired corrosion resistance), a thermosetting resin matrix (most commonly Vinylester, Polyester, or sometimes Epoxy), and various additives. Additives may include catalysts, accelerators, internal mold release agents, UV inhibitors, and pigments. The choice of glass fiber and resin significantly influences the final mechanical properties, chemical resistance, and cost of the FRP rebar. Quality and consistency of these raw materials are crucial for the performance of the final product and efficient operation of the gfrp rebar machine.

- Q4: How does the maintenance for an FRP Rebar Machine compare to other industrial equipment?

- A4: Maintenance for an FRP Rebar Machine is primarily focused on regular cleaning of the resin bath and dies, inspection and replacement of wear parts (like seals, pulling pads, and cutting blades), and routine checks of electrical and hydraulic systems. Compared to heavy machinery involved in casting or forging, the mechanical wear on a pultrusion machine is generally lower. However, due to the corrosive nature of some resins and the continuous operation, diligent preventative maintenance is essential to ensure consistent product quality and minimize unscheduled downtime. Manufacturers provide detailed maintenance manuals and recommend maintenance schedules to optimize machine longevity and performance.

Conclusion: The Future of Reinforcement through Advanced Manufacturing

The evolution of the frp rebar machine has fundamentally reshaped the landscape of reinforcement materials, offering a compelling alternative to traditional steel in an increasingly diverse range of applications. As construction demands shift towards greater durability, resilience, and sustainability, FRP rebar stands out as a superior solution, particularly in challenging environmental conditions where corrosion is a primary concern. The technical prowess of modern pultrusion equipment, enabling precise control over fiber impregnation, resin curing, and dimensional accuracy, is the bedrock of this material's consistent high performance. From enhancing the lifespan of critical infrastructure like bridges and marine structures to enabling specialized constructions such as MRI-compatible facilities, the impact of FRP rebar is far-reaching. Investing in a state-of-the-art gfrp rebar machine not only provides access to this advanced material but also signifies a commitment to future-proof construction practices, offering significant long-term savings through reduced maintenance and extended service life. The continuous innovation in machine design, coupled with comprehensive technical support and customization options from leading manufacturers, ensures that businesses are well-equipped to meet the growing global demand for this transformative composite material, driving efficiency and sustainability across the built environment.

References

- ACI Committee 440. (2015). Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars (ACI 440.1R-15). American Concrete Institute.

- Benmokrane, B., Wang, P., & Mohamed, H. M. (2017). GFRP reinforcement for concrete structures: Properties and design. Journal of Composites for Construction, 21(5), 04017013.

- Bank, L. C. (2006). Composites for Construction: Structural Design with FRP Materials. John Wiley & Sons.

- Hollaway, L. C. (2010). The Future of Fibre-Reinforced Polymer (FRP) Composites in Construction. In Structures and Architecture (pp. 53-59). CRC Press.

- ASTM International. (2018). ASTM D7957/D7957M-17: Standard Specification for Solid Round Glass Fiber Reinforced Polymer (GFRP) Bars for Concrete Reinforcement. ASTM International.