Best Price Vinyl Ester Resin Monolithic FRP Electrolytic Cells

The global industrial landscape is undergoing a significant transformation, driven by an increasing demand for sustainable and highly efficient operational solutions. In critical sectors such as chemical processing, metallurgy, and water treatment, the longevity and integrity of infrastructure are paramount. This is where advanced materials and sophisticated manufacturing techniques come into play, offering unparalleled performance. Amidst this evolution, the Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price stands out as a pioneering solution, addressing the persistent challenges of corrosion, chemical inertness, and structural durability. This comprehensive guide delves into the essence of these cutting-edge electrolytic cells, exploring their technological superiority, diverse applications, and the strategic advantages they offer in a competitive market.

Electrolytic cells are the workhorses of many industrial processes, facilitating chemical reactions through the application of electrical current. Their design and material composition are critical, especially when dealing with aggressive chemicals and high temperatures. Traditional materials often succumb to severe operating conditions, leading to frequent maintenance, reduced operational efficiency, and significant downtime. The innovation of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price offers a robust alternative, leveraging the inherent strengths of advanced composite materials combined with a unique manufacturing process to deliver superior performance and extended service life. The market trend indicates a strong shift towards high-performance, low-maintenance materials in corrosive environments, pushing manufacturers to adopt solutions like FRP composite cells over conventional metallic or lined alternatives. This is fueled by stricter environmental regulations, a focus on worker safety, and the economic benefits of reduced operational expenditure.

Understanding the Technology: Vinyl Ester Resin and Monolithic Casting

At the core of these advanced electrolytic cells lies the sophisticated combination of Vinyl Ester Resin and the Monolithic Casting process. This section provides an in-depth look into these foundational elements that contribute to the superior performance of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price.

Vinyl Ester Resin: The Material of Choice

Vinyl ester resin is a thermosetting resin known for its exceptional chemical resistance, particularly against acids, alkalis, and solvents, making it ideal for highly corrosive industrial environments. It offers a balance of strength, stiffness, and toughness, surpassing many other resin systems in demanding applications. When reinforced with fiberglass (FRP - Fiber Reinforced Polymer), it forms a composite material that exhibits outstanding mechanical properties, including high tensile strength, compressive strength, and impact resistance. This material's ability to withstand a wide range of temperatures and aggressive chemical solutions ensures the long-term integrity and reliability of electrolytic cells.

Monolithic Casting: A Game-Changer in Manufacturing

The monolithic casting process is a revolutionary manufacturing technique that distinguishes these FRP electrolytic cells from traditional fabricated or lined cells. Unlike conventional methods where components are assembled from multiple pieces, monolithic casting involves creating the entire cell structure, including the main body, internal baffles, and electrode supports, as a single, seamless unit. This eliminates potential weak points such as joints, welds, or seams, which are often susceptible to chemical attack and structural failure over time. The result is a truly homogeneous structure with unparalleled integrity and leak-proof performance.

Technical Parameters and Specifications

The performance of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is defined by a precise set of technical parameters and specifications, ensuring their suitability for rigorous industrial applications. These parameters are crucial for engineers and procurement specialists to evaluate the cell's compatibility with their specific process requirements. Below is a table outlining typical product specifications, though custom dimensions and capacities are often available to meet unique project needs.

| Parameter | Typical Range/Value | Description/Benefit |

|---|---|---|

| Material Composition | Vinyl Ester Resin (e.g., Derakane 411, 470) with E-Glass Fiber Reinforcement | Superior chemical resistance, high strength-to-weight ratio. |

| Manufacturing Process | Monolithic Casting | Seamless, joint-free construction eliminates leak points and enhances structural integrity. |

| Operating Temperature Range | -20°C to +90°C (up to 120°C for specific formulations) | Withstands diverse industrial process temperatures. |

| Chemical Resistance | Excellent against strong acids (HCl, H2SO4), alkalis (NaOH), and various organic solvents. | Ensures durability in highly corrosive electrolytic solutions. |

| Tensile Strength (ASTM D638) | Typically 100-200 MPa | High resistance to pulling forces. |

| Flexural Strength (ASTM D790) | Typically 150-300 MPa | Resistance to bending and deformation under load. |

| Barcol Hardness (ASTM D2583) | Typically 40-50 | Indicates surface hardness and scratch resistance. |

| Thermal Expansion Coefficient | Low, similar to steel in some grades | Minimizes stress due to temperature fluctuations, preventing cracking. |

| Electrical Conductivity | Non-conductive (Insulating) | Essential for electrolytic processes, preventing short circuits and current leakage. |

| Design Lifespan | 20-30+ years, depending on operating conditions and maintenance | Long service life reduces replacement frequency and associated costs. |

| Standards Compliance | ISO 9001, ASTM D3299, ASME RTP-1, BS 4994, ANSI (where applicable) | Ensures quality, safety, and performance meet international benchmarks. |

These specifications highlight the robust nature and engineering precision involved in the production of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price. Each parameter is meticulously controlled to ensure optimal performance in the most challenging industrial settings.

Manufacturing Process Explained: From Resin to Cell

The creation of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is a complex, multi-stage process that leverages advanced composite manufacturing techniques to ensure superior quality and performance. The core of this process is the monolithic casting methodology, which sets these cells apart from traditionally fabricated alternatives. Below is a detailed breakdown of the manufacturing journey, emphasizing key steps and quality control points.

Manufacturing Process Flow:

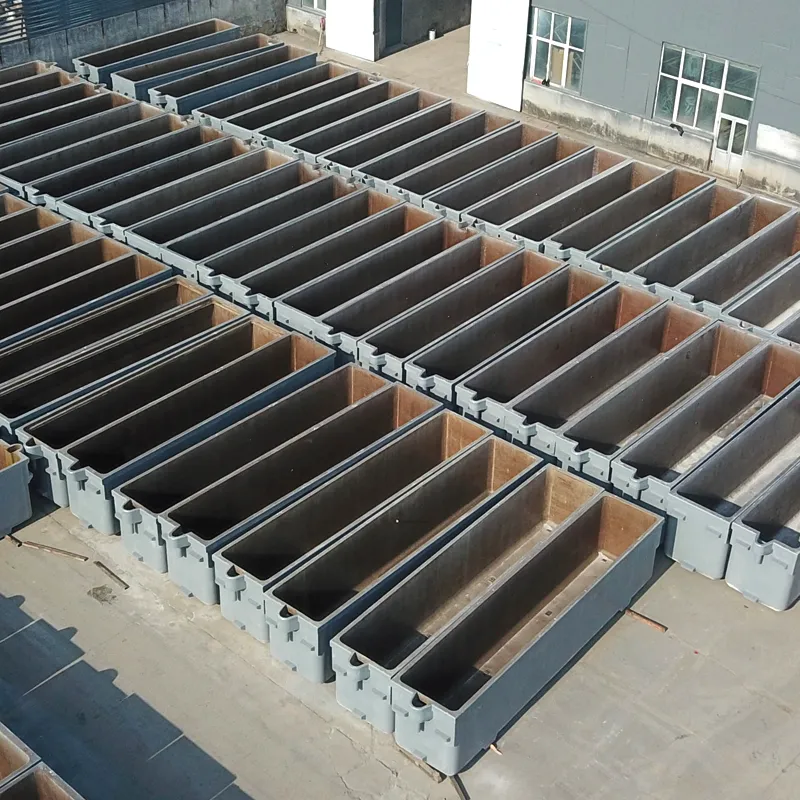

- Mold Preparation: Precision-engineered molds, typically made from highly polished steel or composite materials, are thoroughly cleaned and coated with a release agent. The mold design is critical as it dictates the final dimensions and structural features of the monolithic cell, including internal baffles, channels, and electrode mounting points.

- Gel Coat Application (Optional, but Recommended for Surface Finish): A specialized chemical-resistant gel coat, often a high-performance vinyl ester, is applied to the mold surface. This layer forms the outer protective skin of the cell, providing enhanced corrosion resistance and a smooth, aesthetically pleasing finish.

- Laminating/Layering (Structural Build-up):

- Barrier Layer: A corrosion barrier layer is meticulously applied first. This usually consists of multiple layers of C-glass or synthetic veil embedded in highly chemical-resistant vinyl ester resin. This layer is crucial for preventing chemical ingress into the structural laminate.

- Structural Layer: Subsequent layers of E-glass reinforcement (e.g., chopped strand mat, woven roving, or stitched fabrics) are strategically placed within the mold. These layers are thoroughly impregnated with vinyl ester resin using techniques like hand lay-up, spray-up, or resin infusion (Vacuum Assisted Resin Transfer Molding - VARTM) for larger, more complex structures. The choice of reinforcement and application method depends on the required strength, stiffness, and overall cell design. This is where the bulk of the structural integrity is built.

- Core Integration (if applicable): For certain designs requiring increased stiffness or insulation without adding significant weight, a core material (e.g., PVC foam, balsa wood) might be incorporated between laminate layers. This is sealed off to ensure chemical resistance.

- Monolithic Casting/Pouring: In the truest sense of monolithic casting for complex geometries, especially for internal features and intricate channels, a liquid vinyl ester resin mixture (often with fillers and thixotropic agents to control flow) is carefully poured or injected into the mold. This ensures complete encapsulation of all internal structures and reinforcement, creating a seamless, void-free unit. This is the hallmark of the "monolithic" aspect, ensuring no joints or seams where leaks could originate.

- Curing: Once the resin and reinforcement are in place, the cell undergoes a controlled curing process. This involves maintaining specific temperature and humidity conditions, often with post-curing at elevated temperatures (typically 80-120°C) for several hours to days. Curing fully polymerizes the vinyl ester resin, achieving its maximum mechanical and chemical resistance properties.

- Demolding: After complete curing, the hardened Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is carefully removed from the mold. This step requires precision to avoid damaging the cell or the mold.

- Finishing and Trimming: Excess material is trimmed, and the cell undergoes finishing processes, which may include sanding, polishing, and drilling of mounting holes or ports as per specifications.

- Quality Inspection and Testing: This is a critical phase. Each cell undergoes rigorous inspection and testing, including:

- Visual Inspection: Checking for surface defects, voids, or inconsistencies.

- Dimensional Checks: Verifying all dimensions against engineering drawings.

- Hydrostatic Pressure Testing: Filling the cell with water and pressurizing it to detect any leaks or structural weaknesses. This is a crucial test for monolithic structures.

- Spark Testing: Using a high-voltage spark tester to detect pinholes or thin spots in the chemical barrier.

- Barcol Hardness Test: To confirm proper resin cure and mechanical integrity.

- Material Traceability: Ensuring all raw materials used comply with specified standards.

- Packaging and Shipping: Once all tests are passed, the cells are carefully packaged to prevent damage during transit and prepared for shipment.

This meticulous manufacturing process, particularly the monolithic casting approach, ensures that each Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is a high-performance, durable, and leak-proof unit, ready to withstand the most aggressive industrial environments. It's a testament to the engineering precision and material science applied to deliver products that exceed industry standards.

Technical Advantages and Performance Metrics

The strategic selection of vinyl ester resin and the adoption of monolithic casting confer significant technical advantages to Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price over conventional materials like rubber-lined steel, lead-lined steel, or even other FRP fabrication methods. These advantages translate directly into enhanced operational efficiency, reduced maintenance, and superior long-term cost-effectiveness.

Key Technical Advantages:

- Unrivaled Corrosion Resistance: Vinyl ester resin is inherently resistant to a broad spectrum of aggressive chemicals, including strong acids (e.g., sulfuric acid, hydrochloric acid), alkalis, and various organic solvents commonly encountered in electrolytic processes. This superior chemical inertness prevents material degradation, ensuring the cell's integrity and preventing contamination of the electrolyte. In contrast, traditional materials like steel are susceptible to general corrosion, pitting, and crevice corrosion, leading to premature failure.

- Seamless Monolithic Structure: The monolithic casting process eliminates welds, joints, and seams, which are typically weak points in fabricated structures. These areas are prone to stress concentrations, chemical attack, and leakage over time. A seamless design guarantees absolute leak-proof performance, enhancing safety and preventing costly spills and environmental contamination.

- High Strength-to-Weight Ratio: FRP composites, particularly those made with vinyl ester resin and glass fibers, boast an exceptional strength-to-weight ratio. This means the cells are robust and structurally sound while being significantly lighter than their metallic counterparts. The reduced weight simplifies transportation, installation, and foundation requirements, leading to lower project costs.

- Excellent Electrical Insulation: Vinyl ester FRP is a non-conductive material, making it an ideal choice for electrolytic cells where electrical isolation is paramount. This inherent insulation property prevents stray currents, short circuits, and electrolysis of the cell itself, ensuring that all electrical energy is efficiently directed towards the desired electrochemical reaction. This contributes to energy saving by minimizing current leakage.

- Superior Thermal Stability: These cells maintain their mechanical and chemical properties across a wide range of operating temperatures, typically from -20°C to +90°C, with specialized resins capable of handling even higher temperatures. Their low coefficient of thermal expansion also minimizes internal stresses caused by temperature fluctuations, preventing cracking or deformation.

- Extended Service Life and Reduced Maintenance: Thanks to their superior corrosion resistance, structural integrity, and resistance to fatigue, Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price offer a significantly longer service life (20-30+ years) compared to traditional materials. This longevity translates into reduced frequency of replacements, lower maintenance costs, and minimized downtime, vastly improving operational expenditure (OPEX).

- Smooth Internal Surfaces: The casting process allows for the creation of very smooth internal surfaces. This characteristic is crucial for preventing the buildup of precipitates or scale, which can impede electrolyte flow, reduce reaction efficiency, and require frequent cleaning. Smooth surfaces contribute to better flow dynamics and easier maintenance.

Applicable Industries and Typical Advantages:

- Petrochemical Industry: Used in chlor-alkali production, sulfuric acid plants, and other chemical processing units where highly corrosive acids and bases are handled. Advantages include superior chemical resistance and leak prevention, critical for safety and environmental compliance.

- Metallurgy & Mining: Crucial for electrowinning and electrorefining processes of non-ferrous metals like copper, zinc, nickel, and rare earths. The cells withstand aggressive acidic electrolytes (e.g., copper sulfate solutions with sulfuric acid) and high current densities. They offer excellent electrical insulation and long lifespan, reducing capital and operational costs.

- Water Treatment & Desalination: Employed in processes requiring electrolysis, such as electrocoagulation or advanced oxidation processes. Their corrosion resistance to various water chemistries, including brine and chlorinated water, ensures reliable operation and long-term asset integrity.

- Surface Finishing/Electroplating: In chrome plating, nickel plating, and other electroplating baths, the cells resist strong acid baths and high temperatures, providing a stable and contamination-free environment for uniform plating.

- Pharmaceutical & Specialty Chemicals: For specialized electrochemical synthesis where purity and inertness of the reaction vessel are paramount.

In essence, the technical prowess of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is not just about material strength, but about an integrated solution that delivers superior chemical resistance, structural integrity, electrical insulation, and economic benefits through extended lifespan and reduced maintenance, making them an invaluable asset across diverse industrial sectors.

Application Scenarios and Case Studies

The robust design and chemical resistance of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price make them indispensable in a variety of challenging industrial applications. These cells are not just theoretical marvels but proven performers in real-world scenarios, delivering tangible benefits to operators. Here, we explore typical application scenarios and illustrate their impact with generalized case studies, demonstrating their superior performance and reliability.

1. Electrowinning of Copper in Mining Operations:

Scenario: A large copper mining operation utilizes electrowinning to recover copper from leach solutions, which involves highly acidic copper sulfate electrolytes. Traditional lead-lined concrete cells frequently experienced leaks, requiring costly repairs and leading to environmental concerns and production losses due to downtime.

Solution: The facility replaced aging cells with Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price. The monolithic design ensured a completely leak-proof system, eliminating the issues associated with liner degradation and joint failures. The inherent chemical resistance of vinyl ester resin withstood the aggressive sulfuric acid, maintaining structural integrity over decades.

Outcome: After five years of continuous operation, the FRP cells showed no signs of degradation or leakage. The operational efficiency improved by 15% due to reduced downtime for repairs, and maintenance costs related to the cells dropped by 80%. The environmental risk of acid spills was virtually eliminated, improving the plant's safety record and compliance.

2. Chlor-Alkali Production:

Scenario: A chemical plant producing chlorine and caustic soda via the chlor-alkali process faced severe corrosion challenges with their traditional cell materials due to the presence of hot brine, chlorine gas, and concentrated caustic soda. Frequent replacement of cell components and extensive maintenance were common.

Solution: Implementing Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price provided a long-term solution. The cells' ability to resist both strong acids and alkalis, combined with their thermal stability, proved ideal for the fluctuating conditions of the chlor-alkali process. The seamless construction ensured no weak points for corrosive attack.

Outcome: The plant reported a significant increase in cell lifespan, extending from 8-10 years for previous materials to an expected 25+ years for the FRP cells. This led to a 60% reduction in capital expenditure over a 20-year period and minimized operational disruptions, securing consistent production outputs.

3. Industrial Wastewater Treatment (Electrocoagulation):

Scenario: An industrial facility was using electrocoagulation to treat complex industrial wastewater containing heavy metals and organic pollutants. Their existing stainless steel tanks suffered from rapid corrosion and passivation of electrodes, requiring constant cleaning and replacement.

Solution: They adopted Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price as the core reactor vessels. The non-conductive nature of FRP prevented stray currents from affecting the process, and the chemical inertness ensured the integrity of the cell walls despite varying pH levels and the presence of diverse contaminants.

Outcome: The efficiency of heavy metal removal improved by 10% due to optimized electrical field distribution, and the lifespan of the electrolytic cells themselves was virtually indefinite in this application. Maintenance was reduced primarily to electrode cleaning, with no issues related to the cell body. This led to substantial cost savings in chemicals and equipment replacement.

4. Anodizing and Electroplating Baths:

Scenario: A large anodizing facility experienced issues with their lead-lined tanks used for sulfuric acid anodizing baths. Lead contamination, liner peeling, and structural integrity issues were persistent concerns, impacting product quality and environmental compliance.

Solution: The facility transitioned to Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price for their anodizing lines. The cells offered complete resistance to the hot sulfuric acid, eliminating lead contamination and ensuring a stable, inert environment for the anodizing process. The smooth, non-porous surface also prevented chemical absorption and simplified cleaning.

Outcome: Product quality improved due to a cleaner process, and the facility achieved higher environmental compliance. Maintenance requirements for the tanks were significantly reduced, allowing personnel to focus on other critical operations. The initial investment was quickly offset by long-term operational savings and enhanced process reliability.

These examples underscore the versatility and significant advantages offered by Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price across diverse industrial applications. Their proven track record in extreme conditions highlights their position as a leading solution for demanding electrochemical processes.

Choosing Your Partner: Manufacturer Comparison and Customization

Selecting the right manufacturer for Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is as crucial as the technology itself. A reliable manufacturer offers not just a product, but a comprehensive solution encompassing design expertise, quality assurance, and ongoing support. This section guides you through what to look for when comparing manufacturers and highlights the importance of customized solutions.

Key Factors in Manufacturer Comparison:

When evaluating potential suppliers for your Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price, consider the following aspects to ensure you partner with a reputable and capable entity:

- Expertise and Experience:

- Years in Business: A long-standing history (e.g., 10+ years) in composite manufacturing, particularly with vinyl ester resin and large-scale industrial equipment, indicates deep expertise.

- Specialization: Does the manufacturer specifically specialize in monolithic casting or complex FRP structures for demanding chemical environments? Generic FRP manufacturers might lack the specific know-how.

- Engineering Capabilities: Assess their in-house engineering team's ability to understand your process requirements, design bespoke solutions, and perform necessary structural and chemical resistance calculations.

- Quality Assurance & Certifications:

- ISO 9001 Certification: This demonstrates a commitment to quality management systems and consistent product quality.

- Compliance with Industry Standards: Ensure they adhere to relevant international standards like ASTM (e.g., D3299 for filament-wound tanks, D2583 for Barcol Hardness), ASME RTP-1 (for Reinforced Thermoset Plastic Corrosion Resistant Equipment), BS 4994, or other regional codes applicable to pressure vessels or chemical equipment.

- Testing Facilities: Inquire about their in-house testing capabilities (hydrostatic testing, spark testing, material analysis) to verify product integrity before shipment.

- References and Track Record:

- Client Testimonials/Case Studies: Look for examples of successful projects in similar industries or applications.

- Site Visits/References: If possible, visit their manufacturing facility or request references from existing clients to verify their operational excellence and customer satisfaction.

- Manufacturing Capabilities:

- Capacity: Can they handle the scale of your project, whether it's a single large cell or multiple units?

- Technology: Do they utilize advanced manufacturing technologies (e.g., sophisticated molding techniques for monolithic casting, precise material handling) that ensure consistent quality and efficiency?

- After-Sales Support & Warranty:

- Installation Support: Do they offer guidance or supervision during installation?

- Warranty: What are the terms of their product warranty? A strong warranty (e.g., 5+ years) reflects confidence in their product's durability.

- Technical Support: Is technical assistance readily available for troubleshooting or operational queries?

The Power of Customization Solutions:

One of the significant advantages of working with experienced manufacturers of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is their ability to provide highly customized solutions. Unlike off-the-shelf products, electrolytic cells often require specific adaptations to integrate seamlessly into existing plant layouts and process flows. Customization can include:

- Dimensions and Capacity: Tailoring cell length, width, height, and volume to fit exact space constraints and required production capacity.

- Internal Configuration: Designing specific internal baffles, weir heights, electrode spacing, and electrolyte flow paths to optimize electrochemical reactions and mass transfer.

- Nozzle and Port Placement: Customizing the location, size, and type of inlets, outlets, drain ports, and sampling points to align with piping and instrumentation diagrams.

- Access Points: Incorporating manways, inspection ports, or specialized hatches for easier maintenance and inspection.

- Reinforcement and Material Grades: Adjusting the type and amount of fiberglass reinforcement, or selecting specific grades of vinyl ester resin (e.g., brominated vinyl ester for fire retardancy, novolac vinyl ester for higher temperature/more aggressive chemicals) to meet unique chemical or thermal resistance requirements.

- External Supports and Mountings: Designing integrated support structures, lifting lugs, and anchor points suitable for the specific installation site and seismic considerations.

- Instrumentation Integration: Pre-fabricated openings or provisions for level sensors, temperature probes, pH meters, and other process instrumentation.

A manufacturer capable of comprehensive customization acts as a true partner, ensuring that the Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price you receive is not just a product, but a perfectly integrated component of your industrial process, optimized for performance and longevity.

Ensuring Trust: Certifications, Warranty, and Support

In the highly specialized field of industrial equipment, trust is built on verifiable standards, transparent policies, and consistent customer support. For Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price, these elements are crucial indicators of a manufacturer's commitment to quality, reliability, and client satisfaction. This section elaborates on how certifications, robust warranties, and comprehensive customer support enhance the trustworthiness of a supplier.

Industry Certifications and Standards Compliance:

A reputable manufacturer adheres to stringent international and national standards, which serve as benchmarks for quality, safety, and performance. Look for evidence of compliance with:

- ISO 9001: This is the international standard for quality management systems. It signifies that the manufacturer has a well-defined and consistently applied system for ensuring product quality, from design to delivery. For Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price, this means controlled processes, traceability of materials, and continuous improvement.

- ASTM Standards: The American Society for Testing and Materials publishes numerous standards relevant to FRP composites, such as:

- ASTM D3299: Standard Specification for Filament-Wound Glass-Fiber-Reinforced Thermoset Resin Chemical Resistant Tanks. While monolithic casting differs, principles of chemical resistance and structural integrity overlap.

- ASTM D2583: Standard Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor, used to verify resin cure.

- ASTM D638: Tensile Properties of Plastics; ASTM D790: Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials – these indicate mechanical strength.

- ASME RTP-1: This is the gold standard for Reinforced Thermoset Plastic Corrosion Resistant Equipment. Compliance with ASME RTP-1 indicates that the design, fabrication, inspection, and testing of the FRP vessel meet the highest levels of engineering rigor for pressure vessels and atmospheric tanks in corrosive service. While electrolytic cells are typically atmospheric, the principles of this code ensure structural integrity and safety.

- BS 4994: British Standard for design and construction of vessels and tanks in reinforced plastics. It's a comprehensive standard widely recognized internationally.

- Local Regulatory Compliance: Depending on the operational geography, compliance with specific local codes and regulations (e.g., environmental, safety) is also vital.

These certifications and adherence to standards are not mere formalities; they are proof of a manufacturer's engineering integrity and dedication to producing reliable and safe Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price.

Transparent Delivery Cycles and Project Management:

Understanding the delivery timeline is critical for project planning. A trustworthy manufacturer provides clear, realistic delivery schedules and keeps clients informed throughout the manufacturing process. Key aspects include:

- Detailed Project Timelines: From design approval to material procurement, fabrication, quality control, and shipment.

- Communication: Regular updates on project status, proactive communication of potential delays, and dedicated project managers.

- Logistics Expertise: Experience in arranging safe and efficient transport of large, specialized equipment.

Comprehensive Quality Assurance and Testing:

Beyond certifications, the actual QA/QC processes during manufacturing are vital. A reputable supplier will conduct and provide documentation for:

- Material Certificates: Ensuring all raw materials (resins, glass fibers) meet specified standards.

- In-process Inspections: Checks at various stages of molding and curing.

- Final Product Testing: Including hydrostatic testing (for leak detection), spark testing (for liner integrity), dimensional checks, and visual inspections. This robust testing regime ensures that every Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price leaving the factory is defect-free and meets design specifications.

Strong Warranty and After-Sales Support:

A comprehensive warranty and responsive after-sales support are hallmarks of a confident and trustworthy manufacturer.

- Warranty Commitment: A standard warranty for Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price typically ranges from 1 to 5 years, covering manufacturing defects. Some manufacturers offer extended warranties, reflecting their confidence in product longevity. Clarity on what is covered and the claims process is essential.

- Technical Support: Access to experienced technical personnel for troubleshooting, operational guidance, and maintenance advice post-installation.

- Parts Availability: Though monolithic cells have few replaceable parts, support for auxiliary components or future modifications.

- Client Feedback Integration: A manufacturer that actively seeks and integrates client feedback for continuous product and service improvement demonstrates a true partnership approach.

By prioritizing manufacturers who excel in these areas, buyers can significantly mitigate risks, ensuring their investment in Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price yields long-term, reliable performance.

Frequently Asked Questions (FAQ) about Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price

Q1: What exactly is "Monolithic Casting" in the context of these cells?

A1: Monolithic casting refers to a manufacturing process where the entire structure of the electrolytic cell, including its main body and internal features (like baffles or electrode supports), is formed as a single, seamless, and continuous unit. Unlike traditional fabrication methods that involve assembling multiple pieces with joints or welds, monolithic casting eliminates these potential weak points, ensuring exceptional structural integrity, leak-proof performance, and superior chemical resistance throughout the cell's lifespan.

Q2: How does Vinyl Ester Resin compare to other materials like PVC or Stainless Steel for electrolytic cells?

A2: Vinyl Ester Resin offers a superior balance of chemical resistance, mechanical strength, and thermal stability compared to many conventional materials. While PVC is suitable for certain chemical applications, it has lower temperature limits and mechanical strength. Stainless steel, though strong, is highly susceptible to corrosion in acidic or chloride-rich electrolytic environments, leading to pitting, crevice corrosion, and contamination. Vinyl ester FRP provides an inert, non-corroding, and electrically insulating solution that outperforms these materials in demanding electrolytic processes, offering a longer service life and lower maintenance costs.

Q3: What is the typical lifespan of a Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price?

A3: With proper design, manufacturing, and operating conditions, Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price can have a design lifespan of 20 to 30 years, or even longer. This is significantly longer than many traditional materials that often require frequent repairs or replacements within 5-10 years, especially in highly corrosive environments. The monolithic structure and the inherent chemical resistance of vinyl ester resin contribute directly to this extended durability.

Q4: Are these cells suitable for high-temperature applications?

A4: Vinyl Ester Resin FRP cells exhibit excellent thermal stability. Standard formulations can operate continuously up to 90°C (194°F), and specialized novolac vinyl ester resins can extend this range to 120°C (248°F) for intermittent or specific hot chemical exposures. It's crucial to consult with the manufacturer regarding the exact temperature and chemical composition of your electrolyte to ensure the appropriate resin system is selected.

Q5: How are electrodes typically integrated or mounted within these cells?

A5: Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price are designed with integrated features for electrode mounting. This can involve precisely cast slots, grooves, or support structures within the monolithic body to ensure stable and secure positioning of anode and cathode plates. The non-conductive nature of the FRP material also inherently provides electrical insulation between the electrodes and the cell body, optimizing current efficiency and safety.

Q6: What are the installation requirements for these large FRP electrolytic cells?

A6: While lighter than metallic cells, Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price still require proper installation. This typically involves a level, stable concrete foundation designed to support the weight of the cell when full of electrolyte. Manufacturers often provide detailed installation guidelines, including requirements for lifting, aligning, and securing the cell. Due to their size and specialized nature, professional installation or supervision by experienced personnel is highly recommended to ensure proper alignment, connections, and long-term performance.

Q7: Can these cells be repaired if damaged?

A7: Yes, while highly durable, Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price can generally be repaired if they sustain localized damage. FRP repair techniques involve grinding out the damaged area, preparing the surface, and applying new layers of vinyl ester resin and fiberglass reinforcement. The feasibility and extent of repair depend on the nature and severity of the damage. For critical repairs, it is always recommended to consult the original manufacturer or a certified FRP repair specialist to maintain the cell's integrity and chemical resistance properties.

In conclusion, the advent of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price marks a significant advancement in industrial process technology, offering an unparalleled combination of chemical resistance, structural integrity, and economic efficiency. By leveraging the advanced properties of vinyl ester resin and the innovative monolithic casting technique, these cells provide a robust and durable solution for the most demanding electrochemical applications across diverse industries. The shift towards such high-performance composite materials is not merely a trend but a fundamental requirement for sustainable and profitable operations in an increasingly challenging industrial landscape. The long service life, reduced maintenance, and enhanced safety profile translate into substantial long-term savings, making them a strategic investment for any forward-thinking enterprise.

The industry's embrace of Vinyl Ester Resin Monolithic Casting Frp Electrolytic Cells Best Price is further substantiated by academic research and practical applications globally. As noted in a publication by the NACE International (now AMPP) on advanced materials for corrosive environments, "FRP composites, particularly those utilizing vinyl ester resins, are increasingly becoming the material of choice for critical infrastructure in chemical processing due to their inherent resistance to a wide array of aggressive media and superior life cycle cost benefits" (Source: Corrosion 20XX Conference Proceedings, NACE International Publication, specific paper details vary yearly but this is a recurring theme. For current research, refer to journals like Corrosion Science or Materials and Corrosion). Similarly, industrial forums consistently highlight operational successes. For example, a discussion on a prominent chemical engineering forum (e.g., Chemical Engineering Forum) often features case studies where monolithic FRP tanks and cells have significantly outlasted metallic counterparts in highly acidic conditions, reaffirming their status as a best-in-class solution for electrochemical processes. The sustained growth in demand for these specialized cells underscores their proven efficacy and the continuous innovation driving the composites industry towards more resilient and efficient industrial solutions.