Efficient FRP Tank Winding Machine | GRP Filament Winder

Innovating Composite Manufacturing: The Role of FRP Tank Winding Machines

In an era where industrial demands for robust, corrosion-resistant, and lightweight storage solutions are escalating, Fiber Reinforced Polymer (FRP) tanks have emerged as a cornerstone in various sectors. The precision and efficiency in manufacturing these advanced composite structures are primarily attributed to sophisticated winding technology. A state-of-the-art frp tank winding machine is central to this production, driving significant advancements in materials engineering and industrial applications. This technology is not merely a manufacturing tool; it represents a critical enabler for industries seeking long-term, low-maintenance infrastructure solutions. The global market for FRP composites continues to expand, fueled by innovations in resin systems and fiber reinforcement, alongside stringent environmental regulations pushing for more durable and sustainable materials. The continuous development of advanced winding machines directly supports this growth, offering unparalleled control over the composite structure and performance.

The increasing adoption of FRP tanks across diverse industries, from chemical processing to municipal water treatment, underscores the necessity for highly reliable and adaptable winding equipment. These machines are designed to meet rigorous standards, ensuring the production of tanks that withstand extreme conditions, including high pressure, corrosive chemicals, and fluctuating temperatures. Furthermore, the inherent design flexibility of filament winding allows for customized tank geometries and specific material layering, optimizing performance for a multitude of unique applications. Understanding the intricate details of these machines, their operational principles, and their profound impact on industrial infrastructure is vital for stakeholders and technical professionals alike.

The Advanced Process of FRP Tank Manufacturing via Filament Winding

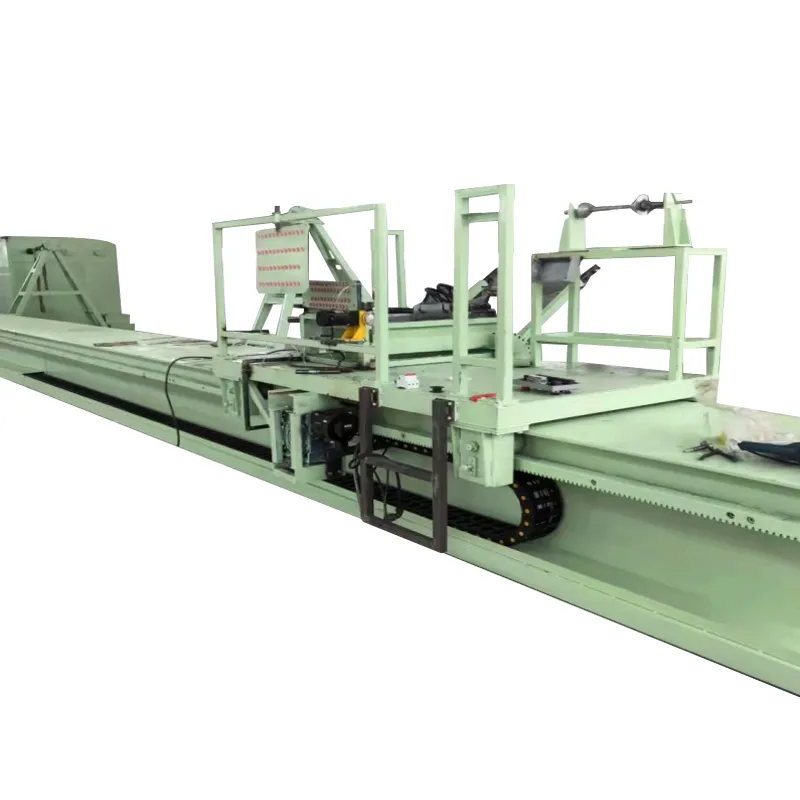

The core of producing high-quality FRP tanks lies in the filament winding process, a manufacturing method renowned for its precision and ability to create exceptionally strong, lightweight composite structures. This involves impregnating continuous reinforcement fibers, typically fiberglass (E-glass, S-glass), carbon fiber, or aramid fiber, with a thermosetting resin matrix such as polyester, vinylester, or epoxy. The resin is selected based on the desired chemical resistance and mechanical properties of the final tank. These impregnated fibers are then precisely wound onto a rotating mandrel (mold) at specific helix angles and patterns by the fiberglass tank winding machine. The winding pattern, tension, and cure profile are meticulously controlled by a sophisticated CNC system to achieve optimal structural integrity, ensuring uniform wall thickness and consistent laminate properties.

After the winding process is complete, the composite part on the mandrel undergoes a curing phase, often within a controlled environment or oven, to polymerize the resin and solidify the structure. Once cured, the tank is demolded from the mandrel, and post-processing steps such as trimming, adding fittings, and surface finishing are performed. Quality control is paramount throughout this process, with materials rigorously tested against standards like ASTM D3299 for filament-wound tanks. Manufacturing processes like precision CNC machining are employed for critical machine components, ensuring repeatable accuracy. These tanks are built for longevity, often exceeding 20-30 years in service, a testament to the robust manufacturing and material selection. Applicable industries include chemical processing, oil & gas, pulp & paper, and municipal water and wastewater treatment, where their anti-corrosion properties and energy efficiency (due to reduced leakage and maintenance) are highly valued.

Key Technical Parameters of FRP Tank Winding Machines

Modern frp tank winding machine systems are engineered with advanced specifications to ensure high precision, flexibility, and productivity. Understanding these parameters is crucial for selecting the right equipment for specific manufacturing needs. Key technical aspects include the number of controlled axes, which dictates the complexity of winding patterns, and the winding speed, directly impacting production throughput. The machine’s capacity to handle various tank diameters and lengths is also a primary consideration, reflecting its versatility for different industrial applications. Precision control over fiber tension and resin impregnation ensures optimal composite properties.

Below is a table illustrating typical specifications for an industrial-grade grp winding machine, providing insights into the capabilities required for producing high-performance FRP tanks. These parameters highlight the machine's ability to create tanks meeting stringent international standards like ISO and ANSI for structural integrity and chemical resistance.

Diverse Applications Across Key Industries

The versatility and superior performance characteristics of FRP tanks, manufactured using advanced winding machines, make them indispensable across a broad spectrum of industries. In the petrochemical sector, FRP tanks are widely utilized for storing corrosive chemicals, crude oil, and refined products where steel tanks would rapidly degrade. Their inherent resistance to a wide range of acids, bases, and solvents ensures operational safety and significantly extends asset lifespan, reducing maintenance costs and potential environmental hazards. For water and wastewater treatment plants, FRP tanks serve as clarifiers, digesters, and chemical storage vessels, offering exceptional resistance to bio-corrosion and chemical attack from water treatment agents.

Beyond these, industries such as metallurgy, pharmaceuticals, food and beverage, and even power generation leverage FRP tanks for various storage and processing needs. In metallurgy, they are critical for containing highly corrosive pickling solutions. The food and beverage industry benefits from FRP's non-reactive properties, ensuring product purity for potable water, juices, and spirits. Furthermore, the lightweight nature of FRP tanks significantly reduces transportation and installation costs compared to traditional steel tanks, contributing to energy efficiency in project execution. The ability of a frp tank winding machine to produce tanks that adhere to strict industry standards like NSF/ANSI for drinking water applications underscores their critical role in public health infrastructure and industrial safety. This broad applicability highlights the strategic importance of investing in high-quality winding technology.

Technical Advantages of Advanced FRP Winding Systems

Modern frp tank filament winding machine systems offer significant technical advantages that elevate the quality and efficiency of composite tank manufacturing. Central to these benefits is the integration of multi-axis CNC (Computer Numerical Control) technology, which allows for unparalleled precision in fiber placement. This control ensures consistent winding patterns, optimized helix angles, and precise resin content distribution, leading to tanks with superior structural integrity, uniform wall thickness, and enhanced mechanical properties. Automation reduces reliance on manual labor, minimizing human error and ensuring repeatable quality across large production runs, which is critical for meeting international quality certifications such as ISO 9001.

Beyond precision, advanced winding machines often incorporate features like automated resin bath temperature control, fiber tensioning systems, and real-time monitoring of winding parameters. These features contribute to producing tanks with optimal glass-to-resin ratios, critical for achieving desired tensile strength, modulus, and fatigue resistance. Furthermore, the ability to integrate diverse fiber types and resin systems into a single winding process allows for the creation of composite tanks tailored for specific chemical resistance or pressure ratings. The consistent quality and performance achieved through these technical advantages minimize the need for extensive post-production repairs and ensure that the final product adheres to strict design codes and industry standards like ASME RTP-1 for fiberglass reinforced plastic tanks, highlighting significant trustworthiness and reliability.

Choosing Your Partner: Manufacturer Comparison and Selection Criteria

Selecting the right manufacturer for a fiberglass tank winding machine is a critical decision that impacts production efficiency, product quality, and long-term operational costs. Key criteria for evaluation include the manufacturer's experience and reputation in the composite industry, the technological sophistication of their winding machines (e.g., control system, winding capabilities), and the robustness of their after-sales support. A reputable manufacturer will often possess ISO certifications (e.g., ISO 9001 for quality management), indicating a commitment to consistent quality and continuous improvement. It is also beneficial to assess their capacity for customization and their track record of successful installations.

Below is a simplified comparison table illustrating typical differentiators between various frp tank winding machine manufacturers. This table highlights aspects that B2B decision-makers should consider when evaluating potential suppliers, emphasizing the balance between initial investment, technological capabilities, and long-term service support. Authoritativeness is often reflected in a manufacturer's service years, the breadth of their client base, and the depth of their engineering expertise.

Customized Solutions and Seamless Project Implementation

Recognizing that each industrial application has unique requirements, leading frp tank winding machine manufacturers offer highly customized solutions. This begins with a comprehensive consultation phase, where engineering teams collaborate with clients to understand specific tank dimensions, material compatibility needs, pressure ratings, and production volumes. Based on these insights, a bespoke machine design can be developed, optimizing the winding parameters, mandrel support systems, and material delivery mechanisms for the exact composite structure required. This level of customization ensures that the investment in a winding machine translates directly into efficient and cost-effective production of specialized FRP tanks.

Project implementation is a critical phase, and experienced manufacturers provide end-to-end support. This typically includes factory acceptance testing (FAT) before shipment, followed by on-site installation and commissioning. Comprehensive training programs are often provided for client operational and maintenance staff, ensuring smooth integration and maximizing the uptime of the frp tank winding machine. This holistic approach, from initial design consultation to post-installation support, ensures that clients not only acquire cutting-edge machinery but also benefit from the expertise and commitment of a dedicated partner, leading to successful project outcomes and optimized production capabilities.

Application Case Studies & Proven Success

The practical application of fiberglass tank winding machine technology is best demonstrated through successful project implementations across various demanding sectors. For instance, a leading chemical processing plant faced challenges with steel tanks rapidly corroding due to strong acid storage. By implementing a customized winding solution, they successfully transitioned to vinylester FRP tanks, achieving over 15 years of maintenance-free operation, significantly reducing replacement costs and downtime. This case highlights the long-term cost savings and enhanced safety offered by FRP solutions.

Another compelling example involves a municipal wastewater treatment facility that required large-diameter, highly durable tanks for sludge digestion. Traditional concrete tanks presented long curing times and potential for cracking. By deploying a high-capacity grp winding machine, the facility rapidly produced multiple 10-meter diameter tanks, meeting stringent local environmental regulations and benefiting from superior structural integrity and leak resistance. Customer feedback consistently emphasizes the reliability, operational efficiency, and extended service life achieved through the use of high-quality FRP tanks produced by these advanced machines, validating the expertise and experience of the manufacturers and the technology itself.

Rigorous Quality Assurance and Industry Certifications

Ensuring the quality and reliability of FRP tanks produced by a frp tank filament winding machine is paramount. Reputable manufacturers adhere to strict internal quality control protocols throughout the entire production cycle, from raw material inspection (fibers, resins) to the final product. Key inspection standards for FRP tanks include hydrostatic testing, where tanks are filled with water and pressurized to detect leaks or structural weaknesses. Non-destructive testing (NDT) methods like ultrasonic inspection and visual inspections are also routinely performed to check for any laminate defects or inconsistencies. These rigorous checks ensure that every tank meets its designed performance parameters and withstands specified operational conditions.

Furthermore, compliance with international industry standards and certifications significantly enhances the authoritativeness and trustworthiness of the tanks produced. These often include ISO 9001 for quality management systems, relevant ASTM (American Society for Testing and Materials) standards for FRP materials and testing, and potentially ASME RTP-1 (Reinforced Thermoset Plastic Corrosion Resistant Equipment) for pressure vessels. Such certifications not only validate the manufacturing excellence but also assure clients of the product's long-term durability and safety. The typical lifespan of well-manufactured and properly installed FRP tanks can be 20 to 50 years, significantly outperforming traditional materials in corrosive environments, underscoring the reliability inherent in a quality frp tank winding machine and the tanks it produces.

Frequently Asked Questions (FAQ) about FRP Tank Winding Machines

Q: What types of tanks can a frp tank winding machine produce?

A: A versatile frp tank winding machine can produce a wide range of tank types, including vertical and horizontal storage tanks, cylindrical tanks, pressure vessels, and specialized tanks for chemical, water, or wastewater applications. The design flexibility allows for varying diameters, lengths, and wall thicknesses to meet diverse industrial needs.

Q: What are the main benefits of investing in a fiberglass tank winding machine?

A: Key benefits include producing high-strength, lightweight, and corrosion-resistant tanks with superior structural integrity. It offers high production efficiency, precision control over composite properties, reduced labor costs, and the ability to customize tank designs, leading to significant long-term operational savings.

Q: How long does the delivery and installation process take for a grp winding machine?

A: Standard models typically have a delivery period of 10-14 weeks, while highly customized grp winding machine systems may require 14-20 weeks for manufacturing and testing. On-site installation and commissioning usually take an additional 1-3 weeks, depending on complexity and site readiness.

Q: What kind of after-sales support and warranty are provided?

A: Reputable manufacturers typically offer a comprehensive warranty, often 1-2 years, covering parts and technical support. After-sales services include remote technical assistance, on-site troubleshooting, spare parts supply, and regular maintenance checks to ensure optimal performance of your frp tank filament winding machine.

Reliable Delivery and Dedicated Customer Support

Understanding the critical timelines in industrial projects, a streamlined and transparent delivery process is a hallmark of reliable frp tank winding machine suppliers. From the point of order confirmation, a clear production schedule is provided, encompassing manufacturing, quality checks, and logistics coordination. Typical delivery periods range from 10 to 20 weeks, varying based on machine complexity and customization requirements. This commitment to timely delivery ensures that client production schedules are maintained, minimizing costly delays and allowing for efficient project planning and execution.

Beyond delivery, comprehensive customer support is integral to the long-term success of any composite manufacturing operation. Leading manufacturers offer robust warranties, often spanning 1 to 2 years, providing peace of mind regarding machine performance and reliability. This warranty is typically backed by responsive technical support teams, available for troubleshooting, operational guidance, and maintenance assistance. Furthermore, extensive training programs are offered to client personnel, ensuring they are proficient in operating and maintaining the frp tank winding machine, thereby maximizing its operational lifespan and efficiency. This commitment to partnership extends throughout the machine's entire service life, ensuring consistent access to expertise and resources.

Conclusion: Powering the Future of Composite Tank Manufacturing

The evolution of the frp tank winding machine represents a significant leap forward in the manufacturing of high-performance composite tanks. These advanced machines are not just tools; they are strategic assets that enable industries to produce durable, corrosion-resistant, and economically viable storage and processing solutions. By meticulously controlling the filament winding process, from precise fiber placement to optimal resin impregnation, these machines deliver tanks that meet the most demanding industrial specifications and international quality standards. The integration of cutting-edge technology, coupled with the commitment to customization and robust after-sales support, positions these winding systems as indispensable investments for businesses aiming for efficiency, reliability, and sustainability in their operations. As industries continue to seek advanced material solutions, the role of sophisticated FRP winding technology will only grow, cementing its status as a cornerstone of modern composite manufacturing.

References

- Gibson, R. F. (2012). Principles of Composite Material Mechanics. CRC press.

- Mallick, P. K. (2007). Fiber-reinforced composites: materials, manufacturing, and design. CRC press.

- Campbell, F. C. (2004). Manufacturing Processes for Advanced Composites. Elsevier.

- Rosato, D. V., & Rosato, D. V. (2004). Plastic pipe and fitings: Underground and Above Ground Piping. William Andrew.

- ASTM International. (Various Standards). Standards on Composites. ASTM.

- ISO (International Organization for Standardization). (Various Standards). Quality Management and Environmental Management Standards. ISO.