Fiberglass Grating for Sale: Durable & Safe Solutions

The Imperative Role of Fiberglass Grating in Modern Industrial Infrastructure

In today's rapidly evolving industrial landscape, the demand for resilient, cost-effective, and safe infrastructure materials is paramount. Traditional materials often fall short in corrosive environments, demanding high maintenance and frequent replacements. This is where advanced composite solutions, specifically fiberglass grating, emerge as a superior alternative. Fiberglass grating, or Fiber Reinforced Polymer (FRP) grating, offers an unparalleled combination of strength, chemical resistance, anti-slip properties, and ease of installation, making it indispensable across a multitude of sectors. The market for these advanced materials is experiencing robust growth, driven by increasing awareness of lifecycle costs and stringent safety regulations. Understanding the full spectrum of its benefits, from material composition to application advantages, is crucial for B2B decision-makers seeking durable and efficient infrastructure solutions.

The global fiberglass composites market is projected to reach significant valuations, underscoring the expanding applications of fiberglass grating for sale. This growth is fueled by their inherent advantages over metallic alternatives, particularly in environments prone to corrosion, such as chemical plants, water treatment facilities, and offshore platforms. Key drivers include the push for sustainable solutions, the need for lightweight yet strong materials in infrastructure development, and the increasing adoption in renewable energy sectors. Furthermore, the versatility of fiberglass composites extends beyond grating to include related products like fiberglass rods for sale used in structural reinforcement, fiberglass tubing suppliers providing conduits for various applications, and the robust demand reflected in fiberglass tank price trends. These interconnected sectors highlight a broader shift towards high-performance fiberglass products that offer long-term value and operational safety across industries.

Precision Engineering: The Manufacturing Process of Fiberglass Grating

The production of high-quality fiberglass grating involves sophisticated manufacturing processes designed to imbue the final product with superior mechanical and chemical properties. The primary materials consist of premium-grade fiberglass roving, which provides the structural integrity, impregnated with a thermosetting resin matrix such as Isophthalic Polyester, Vinyl Ester, or Phenolic resin. Each resin type offers distinct advantages, with Isophthalic being general-purpose and cost-effective, Vinyl Ester providing excellent resistance to a broad range of corrosive chemicals, and Phenolic offering exceptional fire retardancy and low smoke emission. The choice of resin is critical, directly impacting the grating's performance in specific industrial environments and determining its suitability for extreme temperatures, chemical exposure, or flame spread requirements. This careful selection ensures that the fiberglass grating can withstand harsh conditions while maintaining its structural integrity and safety features throughout its operational lifespan.

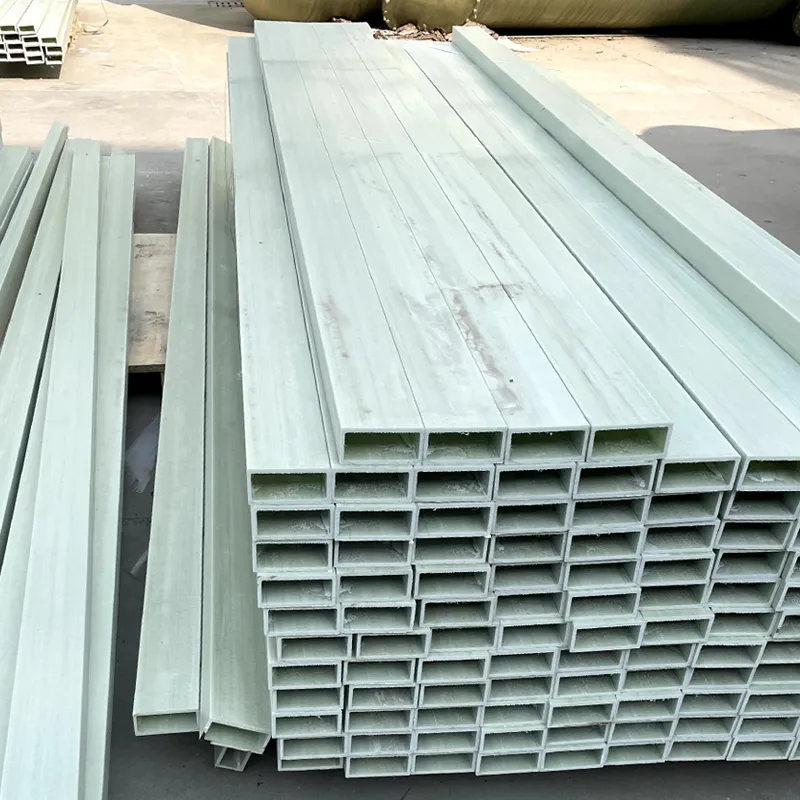

Two predominant manufacturing methods define the production of fiberglass grating: molded and pultruded. Molded fiberglass grating is manufactured by placing continuous glass fibers in a liquid resin bath and then pouring the saturated mixture into a large, heated mold. After curing, the panels are ejected, resulting in a monolithic, one-piece structure that offers bidirectional strength. This process is highly effective for producing panels with specific mesh patterns and allows for integrated anti-slip surfaces directly during the molding process, ensuring a durable bond. Pultruded fiberglass grating, on the other hand, is created by continuously pulling fiberglass rovings and mats through a resin bath and then through a heated die. This continuous process produces individual load-bearing bars and cross-rods that are then mechanically interlocked or adhesively bonded to form the grating panel. Pultruded grating excels in applications requiring high unidirectional strength and longer unsupported spans, making it ideal for walkways, trench covers, and structural platforms.

Quality control is an integral part of the manufacturing lifecycle for any reputable fiberglass grating supplier. This involves rigorous inspection standards, including adherence to international benchmarks such as ISO 9001 for quality management systems and ANSI/NAAMM standards for FRP grating. Specific tests include load-deflection testing to verify load-bearing capacity, ASTM E-84 testing for flame spread and smoke development ratings, and chemical immersion tests to confirm corrosion resistance under various conditions. Furthermore, UV stability tests ensure long-term performance in outdoor applications, preventing degradation from sunlight exposure and maintaining color integrity. These stringent checks guarantee that every panel of fiberglass grating for sale meets the highest performance and safety specifications, ensuring reliability and a long service life, typically exceeding 20 years even in aggressive industrial environments.

Technical Parameters & Performance Benchmarks

Selecting the right fiberglass grating for a specific application requires a detailed understanding of its technical parameters. These specifications directly dictate the grating's suitability for various load conditions, environmental exposures, and safety requirements. Key parameters include panel thickness, mesh size (e.g., 1.5" x 1.5" square, 1" x 4" rectangular), load-bearing capacity, deflection characteristics under specified loads, and resin system composition. For instance, a larger mesh size offers a higher open area for drainage but may have lower load capacity or require closer support. Conversely, a smaller mesh provides a more solid walking surface, preventing small objects from falling through and offering greater load distribution. These precise specifications are critical for engineers and procurement specialists to ensure optimal performance, compliance with industry regulations, and long-term structural integrity for project demands.

To provide a clearer perspective on the diverse range of fiberglass grating for sale, the following table outlines common specifications and performance benchmarks. This data is derived from typical industry standards and product offerings, providing a foundational reference for material selection and design. It emphasizes key factors like panel dimensions, load capabilities, and environmental resistances, which are crucial for engineering evaluations.

| Parameter | Common Range / Value | Unit / Standard | Notes on Application |

|---|---|---|---|

| Panel Thickness | 25mm (1"), 38mm (1.5"), 50mm (2") | mm / inch | Determines load capacity and span capabilities; thicker panels handle heavier loads. |

| Mesh Size (Molded) | 38x38mm, 50x50mm, 25x25mm | mm | Open area, slip resistance, and pedestrian comfort; typically square mesh. |

| Bearing Bar Depth (Pultruded) | 25mm (1") to 150mm (6") | mm / inch | Crucial for load capacity and span in unidirectional applications; deeper bars for longer spans. |

| Resin System | Isophthalic, Vinyl Ester, Phenolic | Type | Corrosion resistance, fire retardancy, and temperature limits vary by resin. |

| Flame Spread Rating | ASTM E-84, Class 1 (25 or less) | Index | Critical for safety in fire-sensitive environments, indicates combustibility. |

| Temperature Range | -50°C to +100°C (Isophthalic), +120°C (Vinyl Ester), +180°C (Phenolic) | °C | Ensures stability and performance in extreme thermal conditions without degradation. |

| Slip Resistance | Concave, Grit Top, Checkered Plate | Surface Finish | Enhances safety in wet or oily conditions, often measured by Coefficient of Friction (COF). |

In addition to these core parameters, supplementary technical data such as Coefficient of Friction (COF), impact resistance, and electrical conductivity are often provided. Fiberglass grating, being non-conductive, offers a significant safety advantage in electrical applications where stray currents pose a risk. Its low thermal conductivity also means it remains comfortable to touch even in extreme ambient temperatures, unlike metal grating which can become dangerously hot or cold. For custom requirements, manufacturers often provide detailed engineering data sheets and span tables, allowing engineers to precisely calculate the appropriate grating type and support structure for their specific projects. This level of detail ensures that every installation of fiberglass grating for sale is optimized for both safety and performance, minimizing risks and maximizing operational efficiency.

Versatile Applications & Unmatched Advantages

Fiberglass grating has found extensive application across a diverse range of industries, thanks to its unique combination of properties that address critical operational challenges. In the petrochemical sector, its superior corrosion resistance to acids, alkalis, and salts makes it ideal for walkways, platforms, and trench covers around chemical processing tanks and pipes, where metallic grating would rapidly degrade, necessitating frequent replacement and incurring high maintenance costs. Similarly, in water and wastewater treatment plants, fiberglass grating is indispensable for filter floors, clarifier walkways, and manhole covers due to its non-corrosive nature and resistance to microbial growth, ensuring long-term hygiene and structural integrity in persistently wet environments. The material's lightweight characteristic significantly reduces installation costs and makes handling easier, a key advantage over heavy steel alternatives, especially in remote or difficult-to-access locations.

Beyond these traditional heavy industries, fiberglass grating for sale is increasingly being adopted in commercial and architectural applications. Its aesthetic appeal, combined with properties like UV stability and choice of colors, allows architects to integrate it into building facades, sunscreens, and decorative elements, offering both functionality and modern design. In the food and beverage industry, its non-porous surface and ease of cleaning make it suitable for processing areas, ensuring stringent hygiene standards are met and preventing bacterial buildup. The mining and metallurgical sectors benefit from its robust performance in abrasive and harsh environments, where it serves as elevated walkways, access platforms, and conveyor crossovers, withstanding heavy impacts and constant wear. The non-magnetic nature of FRP grating is also highly valued in sensitive environments like MRI rooms or areas with high electromagnetic interference, where traditional metals would be problematic, ensuring equipment performance and patient safety.

The technical advantages of fiberglass grating are manifold and contribute significantly to reduced lifecycle costs and enhanced operational safety. Its superior corrosion resistance translates to minimal maintenance and extended service life, drastically lowering replacement frequency compared to steel, resulting in substantial long-term savings. The inherent anti-slip surface, often enhanced with grit top finishes, significantly reduces the risk of slips and falls, a major contributor to industrial accidents, thus improving workplace safety. Furthermore, fiberglass grating is electrically non-conductive and thermally insulating, providing crucial safety in environments with electrical hazards or extreme temperatures, protecting personnel from shocks and burns. Its lightweight nature simplifies transportation and installation, leading to substantial labor and equipment savings, making projects more efficient. These combined attributes make fiberglass grating an economically sound and technologically advanced choice for modern industrial infrastructure, providing a high return on investment.

Choosing the Right Supplier: Manufacturer Comparison & Custom Solutions

When sourcing fiberglass grating for sale, selecting a reliable manufacturer is as critical as understanding the product itself. Reputable suppliers distinguish themselves through adherence to international quality standards, demonstrable project experience, and a commitment to customer support. Key differentiators include comprehensive product warranties, certifications like ISO 9001, and the ability to provide detailed engineering support and custom fabrication services tailored to specific client needs. Companies with a long track record in the industry, offering a broad portfolio of fiberglass products including fiberglass rods for sale and partnerships with leading fiberglass tubing suppliers, often possess deeper technical expertise and more robust supply chains. A thorough evaluation of a manufacturer's production capabilities, quality control protocols, and post-sales support infrastructure is essential for long-term project success and minimizing risks.

Beyond standard product lines, the ability to provide customized fiberglass grating solutions is a significant advantage for complex industrial projects. Customization can involve specific panel sizes, unique mesh configurations, bespoke resin formulations for extreme chemical environments, or integrated features like embedded conduits for wiring or specific colors for branding or safety coding. A competent supplier will work closely with clients from conceptualization through to installation, offering design assistance, accurate load calculations, and precision cutting/fabrication services to meet precise project requirements. This collaborative approach ensures that the fiberglass grating solution is perfectly tailored, optimizing performance, minimizing waste, and streamlining the installation process. Experienced manufacturers understand that off-the-shelf solutions often fall short in demanding industrial scenarios, making custom engineering a vital service for achieving optimal results.

Our company, with extensive experience in composite solutions, offers a wide array of high-quality fiberglass products, including the Fiberglass Reinforced Stick Strip High Quality Frp Grp Pultruded Profile. We pride ourselves on our rigorous adherence to ISO 9001 quality management systems and a commitment to delivering products that exceed industry benchmarks for durability and performance. Our engineering team provides comprehensive support for customized projects, from initial design consultation to manufacturing and delivery. We ensure that our fiberglass grating and other related products, such as those that impact fiberglass tank price by offering superior materials, provide competitive pricing without compromising on quality or long-term performance. Our long-standing partnerships with leading industrial clients across petrochemical, water treatment, and infrastructure sectors are a testament to our reliability, technical expertise, and dedication to client success.

Application Case Studies & Client Successes

Demonstrating the practical benefits of fiberglass grating, several case studies highlight its transformative impact across various industrial settings. In a major chemical processing plant, conventional steel grating in a highly acidic area required replacement every 18 months due to severe corrosion and structural degradation. Upon implementing vinyl ester fiberglass grating, the client reported zero signs of corrosion after five years of continuous operation, leading to significant maintenance cost reductions and uninterrupted operational efficiency. This successful transition not only showcased the superior corrosion resistance of FRP but also provided a safer working environment with its inherent anti-slip properties and electrical insulation, reducing risks for personnel working in close proximity to chemical spills or electrical components.

Another notable application involved a municipal wastewater treatment facility facing constant issues with heavy, corroded metal manhole covers and walkways around aeration basins, which posed safety hazards and demanded frequent repair. The installation of lightweight, molded fiberglass grating for sale with a grit top surface resolved these challenges. Workers reported improved safety due to enhanced slip resistance, especially in wet conditions, while the facility achieved considerable savings on installation labor and equipment rental due to the lighter weight and ease of handling. The non-conductive nature also mitigated risks during electrical maintenance operations, enhancing overall site safety. This project underscored the multi-faceted advantages of fiberglass solutions in public infrastructure, ensuring long-term durability, reduced operational expenditure, and improved worker safety for critical municipal services.

Furthermore, a large power generation utility utilized pultruded fiberglass grating for elevated platforms and stair treads in a cooling tower area. The extreme humidity, constant moisture, and corrosive water treatment chemicals had rapidly accelerated corrosion of previous metallic structures, leading to unsafe conditions and costly replacements. The thermal and electrical insulation properties of FRP grating also provided an added layer of safety for personnel working near live electrical components, significantly reducing the risk of accidents. Client feedback consistently highlights the long-term reliability and minimal maintenance requirements of our fiberglass grating, affirming its status as a premium choice for challenging industrial environments where durability and safety are paramount. These tangible results exemplify the superior value proposition of investing in advanced composite materials for critical infrastructure.

Trustworthiness & Customer Support: FAQ & Warranty

Building trust with B2B clients extends beyond product quality to encompass transparent processes and robust customer support. We are committed to providing comprehensive assistance throughout the entire project lifecycle, from initial inquiry to post-installation support. Our dedicated customer service team is equipped to handle complex technical queries, provide detailed product specifications, and offer expert guidance on material selection to ensure optimal project outcomes. Understanding the complexities of industrial procurement and project deadlines, we emphasize clear communication regarding lead times, precise delivery schedules, and efficient shipping logistics, ensuring that clients receive their fiberglass grating for sale and other essential fiberglass products precisely when needed to maintain project timelines and avoid costly delays.

Frequently Asked Questions (FAQ)

Q1: What are the primary advantages of fiberglass grating over steel grating?

A1: Fiberglass grating offers superior corrosion resistance, making it ideal for harsh chemical environments. It is significantly lighter, easier to install with standard tools, electrically non-conductive, and thermally insulating. Its long service life and minimal maintenance translate to lower lifecycle costs and enhanced safety compared to traditional steel grating.

Q2: How is the load-bearing capacity of fiberglass grating determined?

A2: Load capacity is determined by factors such as panel thickness, mesh size, resin type, and unsupported span length. Our engineers provide detailed span tables and perform precise load calculations based on recognized industry standards (e.g., ANSI/NAAMM, ASTM) to ensure the grating meets specific project requirements safely and efficiently.

Q3: Can fiberglass grating be customized for specific applications?

A3: Absolutely. We offer extensive customization options, including specific panel dimensions, unique mesh configurations, bespoke resin systems (e.g., Vinyl Ester for extreme chemicals, Phenolic for superior fire resistance), custom colors, and various surface finishes (e.g., grit top for enhanced slip resistance). Our advanced fabrication services allow for precision cutting and fitting to exact project specifications.

Q4: What is the expected delivery timeframe for fiberglass grating orders?

A4: Standard orders for common sizes typically ship within 2-4 weeks, depending on quantity and current demand. For large volume or highly customized orders, delivery schedules are determined in close consultation with the client to align seamlessly with project timelines. We prioritize efficient production and logistics to ensure timely project completion.

Q5: What warranty is provided with your fiberglass grating products?

A5: We offer a comprehensive 5-year limited warranty on our fiberglass grating against manufacturing defects and material failures under normal use and conditions. This warranty reflects our unwavering confidence in the durability, quality, and long-term performance of our products, ensuring peace of mind and secure investment for our clients.

Our commitment to quality is reinforced by our ISO 9001 certification, underscoring our strict adherence to international standards for quality management systems and continuous improvement. This certification, coupled with rigorous in-house testing and independent third-party verification, ensures that every product, including our specialized Fiberglass Reinforced Stick Strip High Quality Frp Grp Pultruded Profile, meets and often exceeds stringent performance criteria. We believe that transparency in our processes and unwavering support for our clients are foundational to fostering lasting business relationships and delivering superior value that contributes directly to their operational success.

Further Resources & Academic Citations

For those seeking to delve deeper into the technical aspects and material science behind fiberglass composites and grating applications, the following academic and industry resources provide authoritative information, research findings, and standardized specifications:

- American Society for Testing and Materials (ASTM) International. "Standard Specification for Fiber-Reinforced Polymer (FRP) Grating Used in Corrosive Environments." ASTM D6285.

- National Association of Architectural Metal Manufacturers (NAAMM). "NAAMM MBG 531: FRP Grating Manual for Pultruded and Molded Grating."

- Bank, L. C. (2006). Composites for construction: Structural design with FRP materials. John Wiley & Sons.

- GangaRao, H. V. S., & Taly, N. (2006). Fiber-reinforced polymer composites in construction. CRC press.

- Fiberglass Reinforced Plastics (FRP) Institute Technical Papers and Research Publications.