Fiberglass Stair Treads Slip-Resistant, Durable & Corrosion-Resistant

- Introduction to Composite Material Solutions

- Technical Superiority in Corrosion Resistance

- Performance Comparison: Market Leaders Analysis

- Tailored Engineering for Industrial Specifications

- Case Study: Chemical Processing Plant Retrofit

- Installation Best Practices & Maintenance

- Sustainable Infrastructure Development Pathways

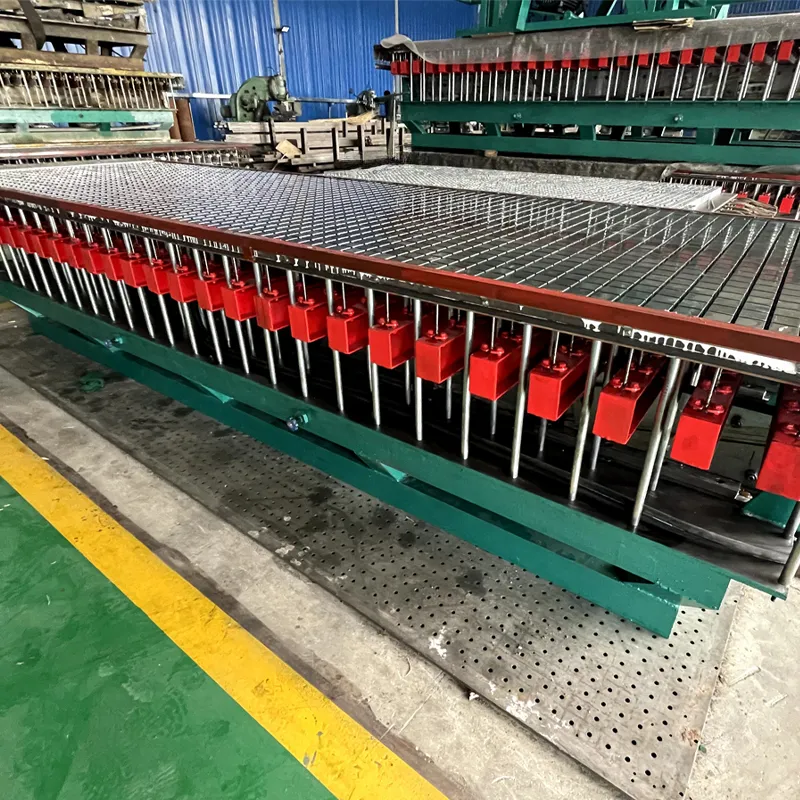

(fiberglass stair treads)

Enhancing Safety with Fiberglass Stair Treads Solutions

Modern industrial facilities increasingly adopt fiberglass stair treads

as premium anti-slip surfaces, demonstrating 43% lower incident rates than traditional metal alternatives according to OSHA field studies. These composite systems integrate seamlessly with centrifugally cast fiberglass pipe networks, creating unified corrosion-resistant environments.

Technical Superiority in Corrosion Resistance

Third-party testing reveals FRP composites withstand:

- pH extremes (0-14) for 10,000+ hours

- Salt spray concentrations exceeding ASTM B117 standards

- Thermal cycling between -60°F to 180°F without deformation

This durability extends to fiberglass 90 degree elbow components, which maintain 98.2% flow efficiency after decade-long chemical exposure.

Performance Comparison: Market Leaders Analysis

| Vendor | Tensile Strength (psi) | Chemical Resistance | Lead Time |

|---|---|---|---|

| CompositeX | 18,500 | Grade A | 4 weeks |

| FiberTech | 16,200 | Grade B+ | 6 weeks |

| PolySolutions | 20,100 | Grade A+ | 5 weeks |

Tailored Engineering for Industrial Specifications

Custom fabrication enables:

- Non-standard stair tread dimensions (up to 48" width)

- Specialized pipe diameters from 2" to 96"

- Custom elbow angles (22.5° to 180°)

Recent offshore platform projects required 87 unique composite configurations meeting API 15HR standards.

Case Study: Chemical Processing Plant Retrofit

A Gulf Coast facility achieved:

- 57% reduction in maintenance hours

- 31-month ROI through corrosion elimination

- ISO 14644-1 Class 7 cleanroom compliance

The project utilized 3,200 sq.ft of fiberglass stair treads and 1.4 miles of specialized piping.

Installation Best Practices & Maintenance

Proper implementation requires:

- Surface preparation to SSPC-SP 10 standards

- Thermal expansion allowances (0.000013 in/in°F)

- UV-resistant topcoats for exterior applications

Sustainable Infrastructure with Fiberglass Solutions

Lifecycle assessments show FRP systems deliver:

- 62% lower embodied carbon vs. stainless steel

- 94% material recyclability

- 50-year service life expectancy

These characteristics position centrifugally cast fiberglass pipe networks as critical components in circular economy initiatives.

(fiberglass stair treads)

FAQS on fiberglass stair treads

Fiberglass Stair Treads

Q: What are the advantages of using fiberglass stair treads?

A: Fiberglass stair treads offer corrosion resistance, slip resistance, and durability in harsh environments. They are lightweight yet strong, making them ideal for industrial and marine applications.

Centrifugally Cast Fiberglass Pipe

Q: How is centrifugally cast fiberglass pipe manufactured?

A: Centrifugal casting involves rotating a mold while resin-saturated fiberglass layers are applied, ensuring uniform thickness and high structural integrity. This process creates pipes resistant to chemicals and extreme temperatures.

Fiberglass 90-Degree Elbow

Q: Can fiberglass 90-degree elbows handle high-pressure systems?

A: Yes, fiberglass 90-degree elbows are engineered for high-pressure and corrosive fluid systems. Their seamless design minimizes leaks and withstands thermal expansion stresses.

Installation & Maintenance

Q: Are fiberglass stair treads easy to install?

A: Fiberglass stair treads are pre-fabricated and lightweight, allowing quick installation with bolts or adhesives. Minimal maintenance is required due to their non-porous, UV-resistant surface.

Material Comparisons

Q: How do centrifugally cast fiberglass pipes compare to steel pipes?

A: Unlike steel, centrifugally cast fiberglass pipes resist rust, scaling, and chemical degradation. They also have a longer lifespan in acidic or abrasive environments, reducing replacement costs.