Durable Fiberglass Tanks for Sale Lightweight & Corrosion-Resistant

- Technical advantages of fiberglass storage solutions

- Leading manufacturers and product specifications

- Customization possibilities for specialized applications

- Industry-specific installation case studies

- Maintenance protocols and lifespan expectations

- Purchasing considerations and cost factors

- Implementation planning for industrial projects

(fiberglass tanks for sale)

Why Industries Choose Fiberglass Tanks for Sale

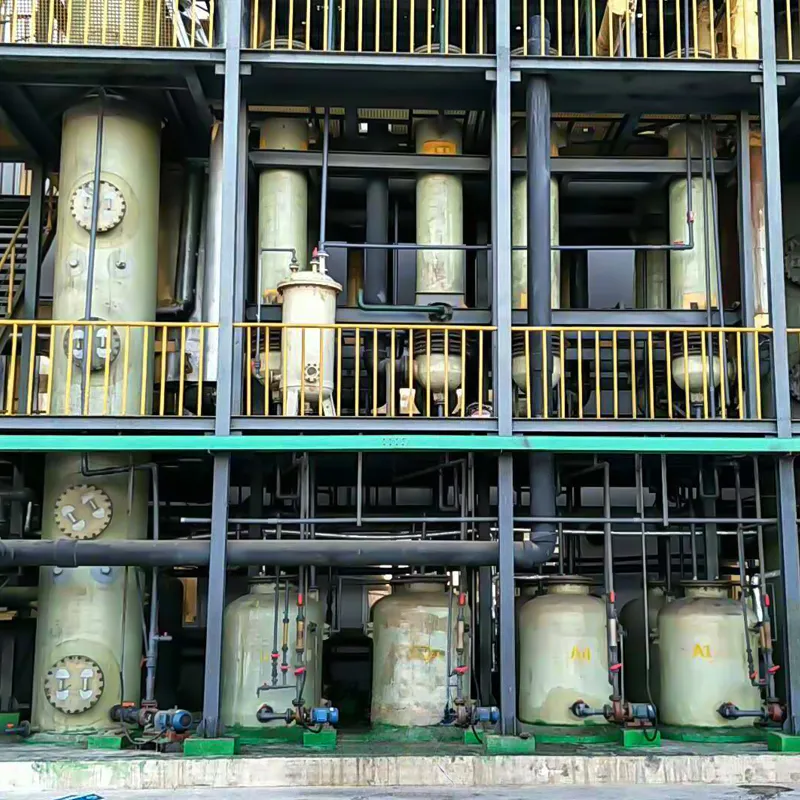

Fiberglass Reinforced Plastic (FRP) tanks deliver unparalleled corrosion resistance across chemical processing, wastewater treatment, and bulk liquid storage applications. Unlike traditional materials, these engineered solutions maintain structural integrity when exposed to hydrochloric acid, sodium hypochlorite, and petroleum derivatives according to ASTM standards. Production data confirms corrosion resistance in 5,000+ chemical combinations – outperforming stainless steel 316L alternatives.

Installation flexibility presents another significant advantage. Large fiberglass tanks for sale

achieve capacities exceeding 50,000 gallons without field welding seams that create potential failure points. Modular assembly allows transport of sectional components to remote locations. The National Science Foundation (NSF-61) certification ensures material safety for potable water storage applications in municipal projects.

Manufacturer Performance Comparison

Leading producers differentiate through material formulations and manufacturing methodologies. Cross-sectional analyses reveal performance variations impacting longevity and chemical compatibility:

| Manufacturer | Wall Thickness (avg) | Pressure Rating (PSI) | Temperature Threshold (°F) | Standard Warranty |

|---|---|---|---|---|

| Containment Solutions | 0.48 in | 22 | 180 | 10 years |

| Fiber Technology Inc. | 0.52 in | 25 | 190 | 15 years |

| Liquid Containment | 0.45 in | 18 | 170 | 8 years |

| Belco Fibreglass | 0.50 in | 20 | 175 | 12 years |

Third-party testing validates superior resin saturation ratios (minimum 70%) from manufacturers utilizing filament winding techniques. ASTM D-3299 certification remains mandatory for tanks handling hazardous materials, ensuring consistent structural performance.

Custom Engineering Capabilities

Bespoke configurations address project-specific requirements beyond standard designs. Engineered modifications include:

- Conical bottoms with 35°–60° slopes for complete drainage

- Reinforced pads accommodating 300 PSI external loading

- Multi-compartment designs separating incompatible fluids

- Insulation systems maintaining ±2°F internal stability

- Seismic bracing compliant with IBC-2018 Zone 4 requirements

Geotechnical assessments determine optimal foundation specifications. California's Orange County Water District installation demonstrates this approach: 38 custom FRP tanks (15,000–30,000 gal) with earthquake restraints withstand 0.58g ground acceleration forces.

Industry Application Case Studies

Municipal Water Treatment: Phoenix installed 27 NSF-61 certified fiberglass water tanks for sale replacing corroded steel reservoirs. The $4.7M project eliminated maintenance expenses averaging $137,000 annually.

Chemical Processing: A Dow Chemical facility utilized custom epoxy-lined FRP tanks for hydrochloric acid storage. Leak incidence decreased by 92% compared to previous titanium vessels, delivering ROI within 26 months.

Agriculture: Nebraska farming cooperative deployed 15 large FRP reservoirs (45,000 gal) for liquid fertilizer storage. UV-resistant gelcoat exteriors prevent degradation from extended sun exposure common in steel alternatives.

Operational Maintenance Protocols

Preventative maintenance extends functional lifespans beyond 35 years. Quarterly inspection checklists should include:

- Ultrasonic thickness testing at 12 designated points

- Visual examination for micro-cracks exceeding 0.01 in

- Flange bolt torque verification (±5% spec)

- Internal coating integrity assessment

Electrochemical impedance spectroscopy identifies early-stage resin degradation. Facilities implementing predictive maintenance report 87% lower failure rates compared to reactive approaches. NSF-P61 compliant potable water tanks require specialized non-toxic repair resins meeting FDA CFR 21.175.300 standards.

Procurement Considerations

Evaluate critical specifications when selecting fiberglass tanks for sale:

Chemical Compatibility: Validate resin formulation against specific stored media using manufacturer chemical resistance charts. Epoxy-vinyl ester compounds provide optimum protection against oxidizing agents like chlorine.

Structural Requirements: Soil bearing capacity must exceed 2,500 PSF for installations without reinforced concrete slabs. Wind load calculations should accommodate 130 MPH gusts for aboveground configurations.

Regulatory Compliance: ASME RTP-1 certification remains essential for pressure vessels. FM Global approval reduces insurance premiums by 15%–22% for industrial facilities.

Transportation logistics present additional considerations: Standard trucking accommodates diameters to 14 ft, while oversized loads require specialized permits increasing costs by 25%–40%.

Implementing Large Fiberglass Tanks for Industrial Projects

Successful installation begins with comprehensive site assessment evaluating soil composition, seismic activity data, and environmental exposure factors. Contractors should follow API 650 Appendix FRP standards during assembly, particularly for hazardous material containment.

Post-installation validation includes hydrostatic testing at 150% operating pressure for 24 hours minimum. Florida-based ethanol producer case study demonstrates best practices: 42 FRP tanks passed 28 psi pressure tests with <0.2% volumetric variation after installation.

Partnering with NRTL-certified manufacturers ensures fabrication consistency. Project managers report 24% shorter commissioning timelines when using vendors providing certified installation supervision.

(fiberglass tanks for sale)

FAQS on fiberglass tanks for sale

Q: What are the advantages of fiberglass water tanks for sale?

A: Fiberglass water tanks are lightweight, corrosion-resistant, and durable. They require minimal maintenance and are ideal for storing potable water, chemicals, or industrial liquids.

Q: How do I choose the right size for large fiberglass tanks for sale?

A: Consider your storage capacity needs, available installation space, and application type. Manufacturers often provide customizable dimensions to fit specific requirements.

Q: Are fiberglass tanks for sale suitable for outdoor use?

A: Yes, fiberglass tanks are UV-resistant and weatherproof. They withstand extreme temperatures and harsh environmental conditions without degradation.

Q: Can fiberglass water tanks for sale handle corrosive substances?

A: Absolutely. Fiberglass tanks are chemically inert, making them perfect for corrosive liquids like acids, alkalis, or saltwater. Always verify compatibility with the manufacturer.

Q: Where can I find reputable suppliers of fiberglass tanks for sale?

A: Search industrial equipment marketplaces, specialized tank manufacturers, or B2B platforms. Ensure suppliers offer certifications like NSF/ANSI 61 for water safety standards.