Mar 06,2025

Sodium Sulfate Production Line

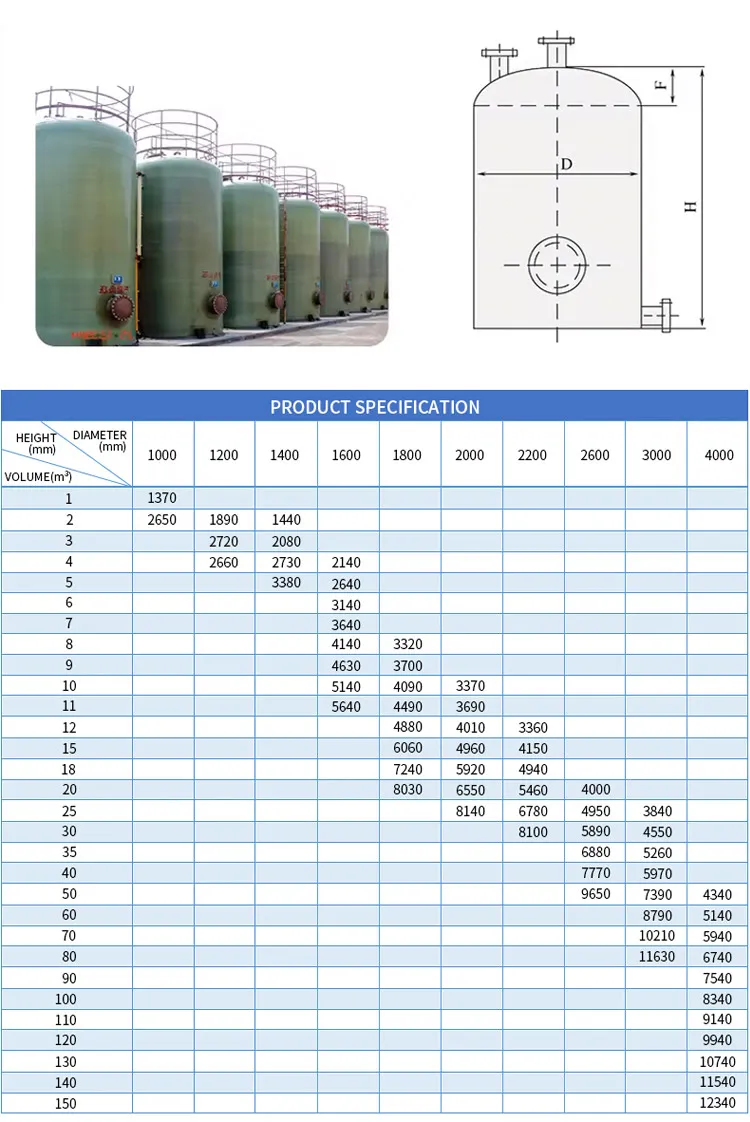

In the realm of advanced water storage solutions, fiberglass pressure tanks are rapidly establishing their foothold as a superior option. These tanks, constructed from robust fiberglass materials, have transformed water storage and pressure maintenance with their intricate blend of durability and innovative design. The use of fiberglass ensures that the tanks are lightweight yet exceptionally strong, making them an ideal choice for a multitude of applications, from residential water systems to industrial processes.

In terms of authoritativeness, leading fiberglass pressure tank manufacturers have invested heavily in research and development to refine the quality and performance of their products. They often conduct rigorous testing to comply with international standards for pressure vessels. These brands also provide extensive product documentation and support to help users optimize tank performance in their specific settings, further establishing their position as industry leaders. It is also essential to highlight the environmental advantages of fiberglass pressure tanks. Unlike their metal counterparts, fiberglass tanks are not prone to leaching materials into the water supply, making them an environmentally friendly choice. Furthermore, the production process for fiberglass uses less energy, and the material itself is recyclable, aligning with global trends towards sustainability. In terms of trustworthiness, fiberglass pressure tanks have garnered positive feedback from a vast pool of consumers and professionals. Testimonials frequently highlight their reliability and long-term savings, with users noting the reduction in maintenance needs and frequent replacements associated with metal tanks. By choosing a reputable brand known for quality and service, consumers can be assured of a trustworthy product that will stand the test of time. For anyone looking to invest in a water storage solution that combines cutting-edge technology with practical application, fiberglass pressure tanks present an outstanding option. They offer unmatched durability, consistent performance, and environmental sustainability, ensuring that water systems operate efficiently and effectively. As technology advances and the demand for quality water management solutions increases, fiberglass pressure tanks remain at the forefront of this vital industry.

In terms of authoritativeness, leading fiberglass pressure tank manufacturers have invested heavily in research and development to refine the quality and performance of their products. They often conduct rigorous testing to comply with international standards for pressure vessels. These brands also provide extensive product documentation and support to help users optimize tank performance in their specific settings, further establishing their position as industry leaders. It is also essential to highlight the environmental advantages of fiberglass pressure tanks. Unlike their metal counterparts, fiberglass tanks are not prone to leaching materials into the water supply, making them an environmentally friendly choice. Furthermore, the production process for fiberglass uses less energy, and the material itself is recyclable, aligning with global trends towards sustainability. In terms of trustworthiness, fiberglass pressure tanks have garnered positive feedback from a vast pool of consumers and professionals. Testimonials frequently highlight their reliability and long-term savings, with users noting the reduction in maintenance needs and frequent replacements associated with metal tanks. By choosing a reputable brand known for quality and service, consumers can be assured of a trustworthy product that will stand the test of time. For anyone looking to invest in a water storage solution that combines cutting-edge technology with practical application, fiberglass pressure tanks present an outstanding option. They offer unmatched durability, consistent performance, and environmental sustainability, ensuring that water systems operate efficiently and effectively. As technology advances and the demand for quality water management solutions increases, fiberglass pressure tanks remain at the forefront of this vital industry.