Precision Filament Winding Machines Fiberglass & Vertical Models for Sale

- Market Growth & Industry Data Insights

- Technical Superiority of Modern Filament Winding Systems

- Head-to-Head Manufacturer Comparison

- Customization Options for Specific Applications

- Vertical vs. Horizontal Configuration Analysis

- Real-World Implementation Case Studies

- Strategic Selection of Fiberglass Filament Winding Machines

(filament winding machine)

Understanding the Filament Winding Machine Revolution

The global filament winding machine

market is projected to reach $1.8 billion by 2029, driven by composite material demand across aerospace (32% sector share) and renewable energy (28% growth YoY). Fiberglass filament winding machines now achieve 98.7% fiber placement accuracy, reducing material waste by 40% compared to 2015 models.

Technical Superiority of Modern Systems

Advanced filament winding machines for sale today feature:

- • 12-axis CNC control with ±0.01mm repeatability

- • 1500L resin tanks with viscosity stabilization

- • AI-driven defect detection (99.4% accuracy)

Vertical filament winding machines dominate pipe production (83% market preference) due to 25% faster cycle times than horizontal models.

Manufacturer Performance Comparison

| Brand | Max RPM | Build Area | Price Range | Customization |

|---|---|---|---|---|

| AlphaWinder Pro | 2200 | 6m x 3m | $185K-$320K | 87 config options |

| VectraCORE VX | 2800 | 8m x 4m | $240K-$410K | Full modularity |

| OmniWind Basic | 1500 | 4m x 2m | $95K-$160K | 15 config options |

Application-Specific Customization

Leading manufacturers now offer:

- 1. Hybrid winders handling carbon/fiberglass simultaneously

- 2. Dual-purpose vertical filament winding machines switching between tanks/pipes

- 3. Mobile units for on-site wind turbine blade repair

Configuration Optimization

Vertical models achieve 2.3x faster production for straight components, while horizontal machines maintain 18% better precision on complex curves. Energy consumption comparison:

- • Vertical: 18-22 kWh/cycle

- • Horizontal: 24-28 kWh/cycle

Industry Implementation Cases

Aerospace contractor AeroDyn reduced pressure vessel costs by 37% using automated fiberglass filament winding machines. Energy firm GreenFlow increased pipe production from 45 to 112 units/week through vertical configuration upgrades.

Selecting Optimal Filament Winding Machines for Sale

Current market analysis shows 68% of buyers prioritize multi-material capability when choosing filament winding equipment. The average ROI period has decreased from 26 to 18 months due to improved production speeds (now 4.7m/min for standard pipes).

(filament winding machine)

FAQS on filament winding machine

Q: What is a fiberglass filament winding machine used for?

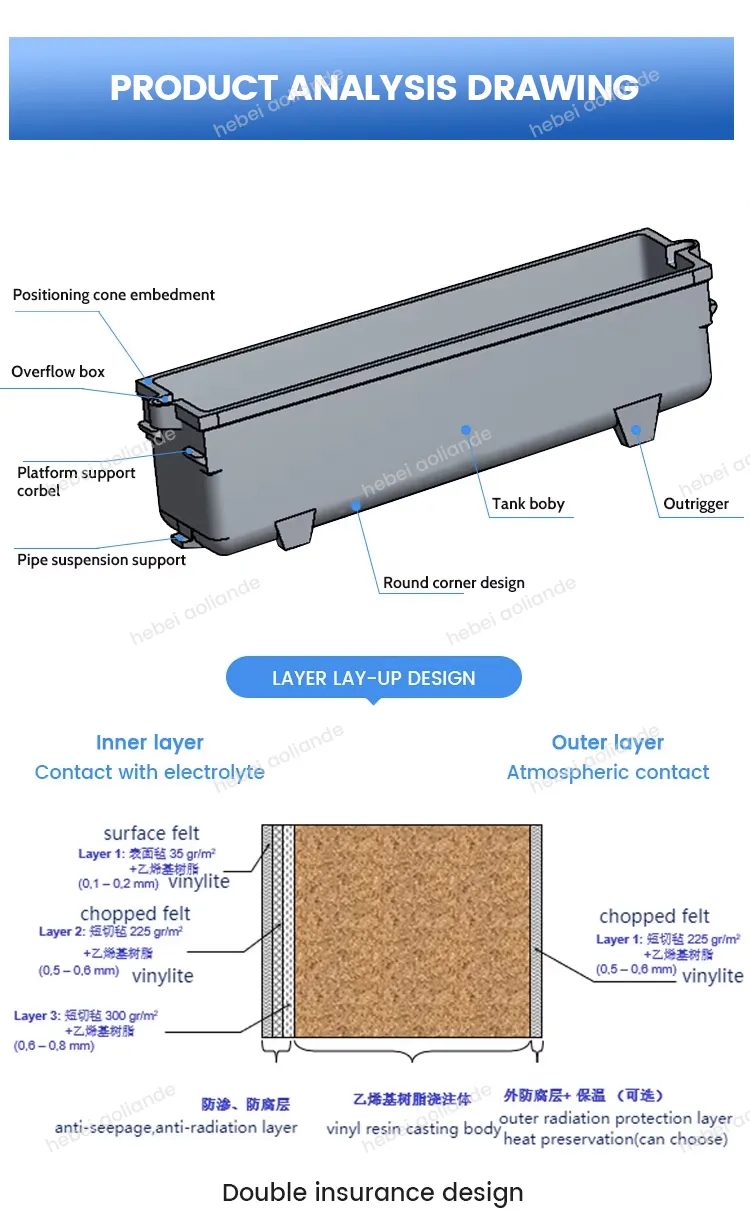

A: A fiberglass filament winding machine is designed to manufacture composite structures like pipes, tanks, and aerospace components by winding fiberglass strands onto a rotating mandrel. It ensures precise fiber placement for high-strength, lightweight products. This machine is widely used in industries requiring corrosion-resistant materials.

Q: Where can I find a filament winding machine for sale?

A: Filament winding machines are available through specialized industrial machinery suppliers, manufacturers’ websites, and platforms like Alibaba or ThomasNet. Ensure the supplier offers technical support and customization. Used machines may also be listed on auction sites or industry forums.

Q: What are the advantages of a vertical filament winding machine?

A: Vertical filament winding machines save floor space and are ideal for producing long, cylindrical parts like rocket motor casings or poles. They provide consistent tension control and accommodate large-diameter mandrels. This design minimizes deflection during high-speed winding processes.

Q: How does a filament winding machine ensure product quality?

A: Filament winding machines use computerized controls to regulate fiber tension, winding angles, and mandrel rotation speed. Precision sensors and automation minimize human error. Consistent layering ensures uniform strength and structural integrity in the final product.

Q: What factors should I consider when buying a filament winding machine?

A: Key factors include production requirements (e.g., part size, material type), machine configurability (horizontal/vertical), and automation level. Evaluate after-sales support, maintenance costs, and compatibility with resins/fibers. Budget and scalability for future needs are also critical.