FRP Tank Winding Machine | Precision Fiberglass Tank Winding

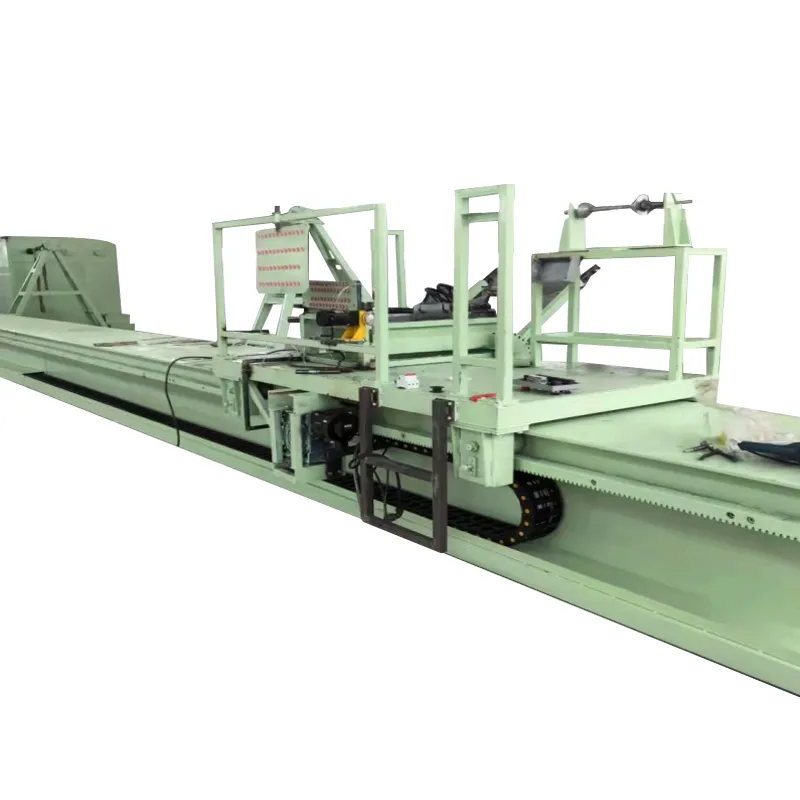

Advancing Composite Manufacturing with frp tank winding machine Technology

The global demand for advanced composite materials, particularly Fiberglass Reinforced Plastic (FRP) tanks, is experiencing significant growth, driven by their superior corrosion resistance, high strength-to-weight ratio, and extended service life. This surge necessitates highly efficient and precise manufacturing solutions, making the frp tank winding machine a cornerstone technology in modern industrial production. These sophisticated machines are pivotal for fabricating large-scale storage and processing vessels used across diverse sectors. Understanding their intricate operational principles, technical advantages, and comprehensive application scope is essential for industry stakeholders seeking to optimize production processes and deliver high-performance composite products.

Industry trends indicate a continuous shift towards automation and precision in composite manufacturing. The market for filament winding technology, a core component of FRP tank production, is projected to expand significantly, fueled by innovations in material science and increasing infrastructure development. Companies are increasingly investing in state-of-the-art fiberglass tank winding machine solutions to meet stringent quality requirements and achieve higher production throughput. The versatility of these machines allows for the fabrication of tanks with various geometries and capacities, crucial for customized industrial applications, ranging from chemical storage to water treatment facilities. This technological evolution ensures that FRP tanks remain a preferred solution over traditional materials like steel or concrete in challenging environments, cementing the importance of reliable frp tank winding machine equipment.

Understanding the FRP Tank Winding Process: From Raw Material to Finished Product

The manufacturing of FRP tanks using a sophisticated grp winding machine involves a meticulously controlled process, beginning with the selection of high-quality raw materials. Typically, this includes E-glass or corrosion-resistant C-glass fibers, saturated with thermosetting resins such as isopthalic polyester, vinyl ester, or epoxy. The choice of resin is critical, dictating the tank's chemical resistance and temperature tolerance. The core manufacturing process, filament winding, is a highly automated technique where continuous rovings of resin-impregnated fibers are wound over a rotating mandrel in a precisely controlled pattern. This method, facilitated by an advanced frp tank winding machine, ensures optimal fiber orientation, leading to superior mechanical properties and consistent wall thickness.

Post-winding, the tank undergoes a curing process, often involving heat, to fully polymerize the resin matrix, solidifying the composite structure. Subsequent steps include demolding, trimming, and the integration of accessories like nozzles, manways, and internal baffles. Critical quality control measures are implemented at every stage. For instance, material integrity is verified through raw material certifications (e.g., ASTM standards), and the finished product undergoes rigorous testing, including hydrostatic pressure tests (conforming to ASME RTP-1 or EN 13121-3), acoustic emission testing, and visual inspections to ensure compliance with international standards like ISO 9001 and ANSI/AWWA D120. These rigorous checks guarantee a design life typically exceeding 20 years, even in highly corrosive environments, making the Frp Tank Machine a reliable investment for industries such as petrochemicals, wastewater treatment, mining, and food processing, where corrosion resistance and structural integrity are paramount, all made possible by precision frp tank winding machine technology.

Key Technical Parameters of Advanced FRP Tank Winding Machines

The performance of an frp tank filament winding machine is defined by a range of critical technical parameters that dictate its efficiency, precision, and the quality of the final product. These parameters are crucial for engineers and procurement managers in selecting the right equipment for their specific production needs. Modern frp tank winding machine systems are typically CNC-controlled, offering unparalleled accuracy in fiber placement and tension control, which directly impacts the structural integrity and uniformity of the tank wall. This level of control minimizes material waste and ensures repeatable quality across production batches.

Below is a table summarizing typical technical specifications for a high-performance Frp Tank Machine, designed for industrial-scale production. These specifications represent the cutting edge of winding technology, emphasizing capacity, precision, and operational flexibility, which are critical considerations for any advanced frp tank winding machine. Understanding these metrics enables stakeholders to forecast production capabilities and ensure compatibility with project requirements.

| Parameter | Typical Specification | Unit |

|---|---|---|

| Max Winding Diameter | 4000 - 25000 | mm |

| Max Winding Length | 12000 - 30000 | mm |

| Winding Speed | 1 - 100 | m/min (mandrel surface) |

| Winding Angle Range | 5° - 90° | Degrees |

| Control System | Siemens/Fanuc CNC | Industrial PC/PLC |

| Number of Axes | 4-6 (Mandrel, Carriage, Cross-feed, Fiber delivery) | Axes |

| Tension Control | Electronic closed-loop | System |

| Machine Footprint | Varies with Max Length | m (Length x Width) |

Diverse Application Scenarios and Unmatched Advantages

The versatility and inherent advantages of FRP tanks, manufactured by a precise fiberglass tank winding machine, make them indispensable across a multitude of industrial applications where conventional materials falter. Their primary benefits include exceptional corrosion resistance to a wide range of chemicals, lightweight properties simplifying transportation and installation, high strength-to-weight ratios ensuring structural integrity, and low thermal conductivity, which contributes to energy efficiency in storing temperature-sensitive substances. Unlike metallic tanks, FRP tanks do not require cathodic protection or internal linings, significantly reducing long-term maintenance costs and operational downtime, showcasing the core benefits of production with a quality frp tank winding machine.

Typical application scenarios for tanks produced by a frp tank winding machine include:

- • Chemical Processing: Storage of corrosive acids, alkalis, and solvents (e.g., hydrochloric acid, sodium hypochlorite), where the chemical inertness of FRP is crucial.

- • Water & Wastewater Treatment: Holding tanks for potable water, industrial wastewater, and process water, including clarifier tanks and chemical dosing tanks, benefiting from FRP's non-corrosive properties.

- • Oil & Gas: Storage of crude oil, produced water, and various chemicals used in exploration and production, particularly in environments with high salinity and aggressive media.

- • Mining & Metallurgy: Slurry tanks, leaching tanks, and process vessels where abrasion and chemical resistance are critical for long-term operations.

- • Power Generation: Demineralized water tanks, cooling water storage, and flue gas desulfurization (FGD) system components, where resistance to aggressive chemical attacks is vital.

- • Food & Beverage: Storage of edible oils, syrups, and various food-grade liquids, benefiting from FRP's inert nature, ease of cleaning, and compliance with hygiene standards.

The superior energy efficiency stems from the lower thermal conductivity of FRP compared to metals, which reduces heat loss or gain, thereby decreasing heating or cooling costs for stored media. This comprehensive suite of advantages positions FRP tanks as a leading solution for demanding industrial applications globally, directly attributable to the precise manufacturing capabilities of the frp tank winding machine.

Technical Superiority and Competitive Edge in Composite Fabrication

Investing in a state-of-the-art frp tank winding machine offers significant technical advantages that translate directly into a competitive edge for manufacturers. Foremost among these is the precision offered by CNC-controlled winding, which allows for exact control over fiber angle, tension, and resin content. This precision is paramount for achieving consistent wall thickness and optimal mechanical properties, leading to tanks that meet stringent performance criteria and maximize service life. The ability to control winding patterns, such as helical or circumferential wraps, enables engineers to design tanks specifically tailored to withstand various stress loads and operating pressures, ensuring structural integrity and reliability of the finished product from a fiberglass tank winding machine.

Furthermore, advanced grp winding machine systems incorporate automated resin impregnation systems, ensuring uniform resin wet-out and reducing air entrapment, which enhances the composite's structural integrity and minimizes porosity. Integrated data acquisition systems monitor critical process parameters in real-time, providing invaluable data for quality assurance and process optimization. This real-time monitoring capability, combined with predictive maintenance features, significantly reduces downtime and improves overall operational efficiency. The robust construction and intelligent design of these machines also allow for rapid changeovers between different tank sizes and configurations, boosting production flexibility and responsiveness to market demands. These technological advancements ensure that manufacturers can produce high-quality FRP tanks efficiently and cost-effectively, maintaining leadership in a competitive market for frp tank winding machine technology.

Selecting Your Partner: Factors in Manufacturer Comparison

When evaluating suppliers for a frp tank winding machine, prospective buyers must consider several critical factors beyond the initial purchase price to ensure a long-term, successful partnership. Key differentiators among manufacturers include their track record and experience in delivering robust and reliable machinery. Look for companies with a proven history of innovation and a deep understanding of composite manufacturing challenges. The quality of after-sales support, including installation, training, spare parts availability, and technical assistance, is paramount. A reliable manufacturer will offer comprehensive service packages to minimize operational disruptions and maximize the lifespan of the equipment.

Another crucial aspect is the manufacturer's commitment to R&D and their ability to offer customizable solutions. A leading provider of fiberglass tank winding machine technology should be able to tailor equipment specifications to unique production requirements, such as specialized winding patterns, integration with existing automation systems, or handling of exotic fiber materials. Certifications such as ISO 9001 and adherence to international safety standards (e.g., CE marking) reflect a manufacturer's commitment to quality and safety. Finally, consider their global reach and network, which can be indicative of their ability to provide timely support and service regardless of your operational location. Engage with a manufacturer that not only sells machines but also offers partnership in developing advanced composite solutions with their frp tank winding machine expertise.

Tailored Solutions: Customizing Your FRP Tank Winding Production Line

Recognizing that no two manufacturing operations are identical, leading providers of frp tank winding machine solutions offer extensive customization options. This bespoke approach ensures that the equipment seamlessly integrates into existing production environments and meets highly specific performance targets. Customization can encompass various aspects, from the machine's physical dimensions to accommodate facility constraints, to advanced software features for intricate winding patterns or real-time process monitoring unique to a client's product portfolio. This flexibility is vital for industries requiring specialized tank geometries, pressure ratings, or material compositions, reinforcing the value of a adaptable grp winding machine.

Customization extends to the entire production line, including resin mixing and delivery systems, curing ovens, material handling equipment (mandrel extractors, tank transporters), and integrated quality inspection tools. For instance, a client requiring tanks for high-pressure gas storage might need an frp tank winding machine capable of very high fiber tension and specific helical winding angles, while another producing large-volume water tanks might prioritize speed and automation. Our Frp Tank Machine solutions are designed with modularity in mind, allowing for future upgrades and scalability. This ensures that your investment remains relevant and productive as your business evolves and market demands shift, providing a robust foundation for long-term growth and operational excellence through tailored composite manufacturing capabilities.

Successful Implementations: FRP Tank Winding Machine in Action

The tangible benefits of utilizing advanced frp tank filament winding machine technology are best illustrated through successful application cases across various industries. For example, a major chemical manufacturer recently upgraded their storage facilities, replacing aging steel tanks with custom-designed FRP vessels produced using a high-precision frp tank winding machine. This transition resulted in a 40% reduction in corrosion-related maintenance costs within the first two years and eliminated the need for frequent internal lining inspections, significantly improving operational safety and efficiency. The lightweight nature of the FRP tanks also facilitated quicker installation, reducing project timelines by 25% compared to traditional materials, highlighting the efficiency gains possible.

Another notable case involves a municipal wastewater treatment plant that implemented a series of large-diameter FRP clarifier tanks. The facility reported enhanced structural integrity and reduced bio-fouling compared to previous concrete structures, due to the smooth, non-porous surface of the FRP. The precision and consistency offered by the frp tank winding machine ensured uniform wall thickness and excellent structural performance, critical for handling large volumes of liquids under continuous operation. These case studies underscore the transformative impact of investing in cutting-edge winding technology, leading to superior product performance, reduced lifecycle costs, and increased operational reliability across demanding industrial applications worldwide.

Frequently Asked Questions (FAQ) about FRP Tank Winding Machines

Q1: What is the typical lead time for a custom frp tank winding machine?

A1: The delivery cycle for a custom Frp Tank Machine typically ranges from 12 to 24 weeks, depending on the complexity of the machine, required customization, and current production schedule. This timeframe includes design, component procurement, manufacturing, assembly, factory acceptance testing (FAT), and preparation for shipment. Expedited options may be available depending on project urgency and specific machine configurations. Clients are provided with a detailed project timeline upon order confirmation to ensure full transparency and timely delivery planning for their new frp tank winding machine.

Q2: What kind of warranty and after-sales support do you offer for the fiberglass tank winding machine?

A2: We stand behind the quality of our Frp Tank Machine with a comprehensive 12 to 24-month warranty on major components, effective from the date of installation or commissioning. Our commitment extends beyond the sale with robust after-sales support, including remote technical assistance, on-site troubleshooting by experienced engineers, regular maintenance advice, and readily available spare parts. We also offer customized service contracts and preventative maintenance programs to ensure long-term optimal performance and minimize operational interruptions for your grp winding machine, guaranteeing peace of mind with your investment in an frp tank winding machine.

Q3: Can your frp tank filament winding machine integrate with existing plant automation systems?

A3: Yes, our advanced Frp Tank Machine systems are designed for seamless integration with a variety of existing plant automation and SCADA (Supervisory Control and Data Acquisition) systems. We utilize industry-standard communication protocols, such as Ethernet/IP, Profinet, and Modbus TCP, to ensure compatibility. Our engineering team works closely with clients to facilitate a smooth integration process, allowing for centralized control, real-time data exchange, and enhanced operational visibility across your entire production line. This capability enhances efficiency and supports a truly smart manufacturing environment enabled by our frp tank winding machine.

Conclusion: Driving Innovation in Composite Tank Manufacturing

The evolution of the frp tank winding machine represents a significant leap forward in composite manufacturing, providing industries with the capability to produce high-performance, durable, and cost-effective FRP tanks. These machines are not merely tools; they are sophisticated engineering systems that enable precise control over material properties, resulting in tanks optimized for specific operational demands. From petrochemical and chemical processing to water treatment and infrastructure, the applications are vast and growing, driven by the inherent advantages of FRP materials over traditional alternatives.

As industries continue to prioritize sustainability, longevity, and operational efficiency, the role of advanced winding technology will only expand. Investing in a cutting-edge fiberglass tank winding machine from a reputable manufacturer ensures access to superior technology, comprehensive support, and tailored solutions that meet the evolving challenges of modern industrial environments. The future of robust and reliable fluid containment solutions is firmly rooted in the capabilities offered by these advanced composite fabrication systems and the continuous innovation in frp tank winding machine technology.

References

- Gay, D., & Tsai, S. W. (2002). Composites manufacturing: Fibre reinforced plastics. Woodhead Publishing.

- Mallick, P. K. (2007). Fiber-reinforced composites: Materials, manufacturing, and design. CRC press.

- ASME RTP-1. (2022). Reinforced Thermoset Plastic Corrosion Resistant Equipment. The American Society of Mechanical Engineers.

- ISO 9001:2015. (2015). Quality management systems — Requirements. International Organization for Standardization.