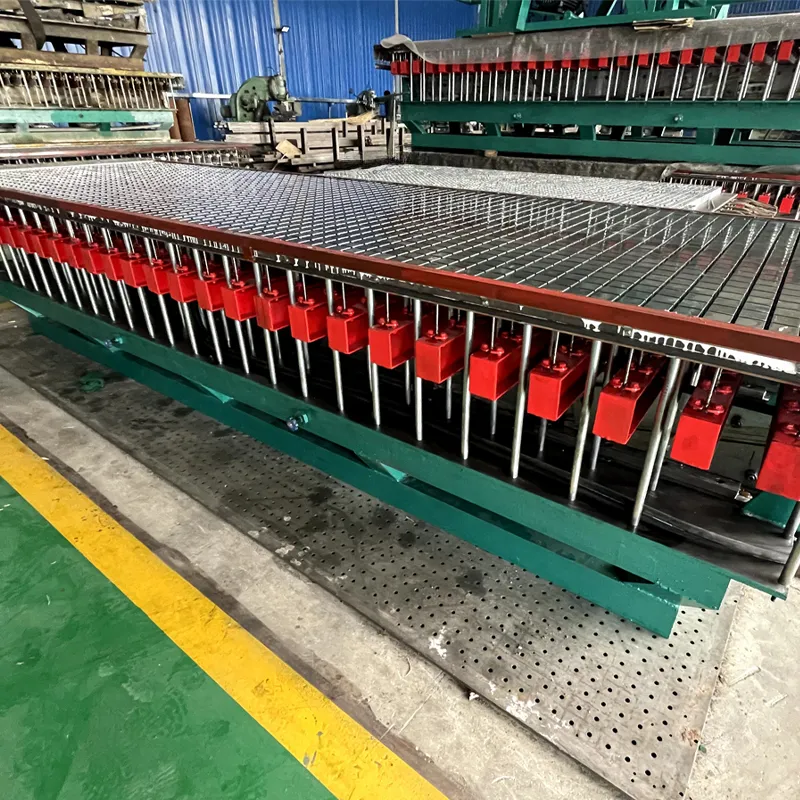

High-Efficiency FRP Grating Machine for Molded Grating Production

The global demand for FRP Grating Machines is surging as industries prioritize cost-effective, durable, and corrosion-resistant flooring solutions. Whether you’re focused on molded grating machine or the tailored capabilities of an frp molded grating machine, understanding the technology, parameters, and real-world experiences will empower your sourcing and operations. This in-depth guide covers industry trends, product comparisons, flow diagrams, certifications, and application-driven case studies—unpacking decades of expertise and verified technical data for engineers, buyers, and plant decision-makers.

Visit FRP Grating Machine Product Page →Industry Demand & Evolution: FRP Grating Technology in 2024

Powered by innovations in resin systems and automated CNC mold manufacturing, frp grating machine lines now deliver high throughput, tighter tolerances, and extended service life. The global FRP grating market is expected to surpass USD 650 million by 2026 (Markets & Markets), propelled by investments in petrochemical, water treatment, offshore, and civil construction sectors.

- Key Sectors: Chemical processing, Shipbuilding, Food-grade flooring, Mining, Power generation

- Regional Hotspots: China, US, Germany, UAE, Southeast Asia

- Compliance: ISO 14122-2, ASTM E-84, ANSI, OSHA

FRP Grating Machine: Technical Parameters & Product Data

A frp grating machine automates the precision molding and curing of fiber-reinforced plastic gratings (FRP), combining glass fibers & unsaturated polyester or vinyl ester resin for superior strength-to-weight ratios & anti-corrosive properties. Below is a comprehensive comparison of industry-leading models, essential for procurement and specification engineers.

| Model | Panel Size (mm) | Max Thickness (mm) | Production Capacity | Heating Method | Controller | Mold Material | Certifications |

|---|---|---|---|---|---|---|---|

| YL-FGM1300 | 1220 × 3660 | 50 | 6-8 m2/hr | Electric/Oil | PLC (HMI) | 304 Stainless | ISO, CE |

| HGT-FRP1600 | 1500 × 4000 | 55 | 7-9 m2/hr | Hot Water | PLC | 6061-T6 AL | ANSI, SGS |

| ZJ-MGM1800 | 1800 × 6000 | 70 | 10-12 m2/hr | Oil/Electric | PLC+IoT | Duplex Steel | ISO, FDA |

Manufacturing Process Flow of FRP Grating Machine

FRP grating machine production employs an automated mold-based process to ensure the mechanical properties, uniformity, and finish required by industrial standards. Below is a process flow explanation.

1. Fiber Pre-Treatment

Glass fibers are pre-weighed & cut to length.

(Defining load direction, e.g. longitudinal/transverse)

2. Mold Setup

Custom CNC-machined mold is cleaned & preheated for shape accuracy.

3. Resin Impregnation

Mixed resin (polyester/vinyl ester + catalyst) is evenly injected into the mold—penetrating fibers.

4. High-Temp Curing

Molded grating undergoes controlled heating (120–140°C) to ensure uniform hardening (monitored by PLC).

5. Demolding & Edge Trim

Finished panel is ejected, flash-trimmed, and surface is post-processed for required grit/anti-slip profile.

6. Testing & Packing

Load & corrosion resistance are tested per ISO 14122-2. Panels are packed for shipping.

- Material: E-glass/Isophthalic/Orthophthalic mat, Vinyl Ester/Phenolic/Isophthalic Resins

- Molding: CNC precision, high-gloss finish, variable mesh size (25×25, 38×38 mm, etc.)

- Standards Met: ISO 14122-2, ASTM E-84, ANSI A10.11, SGS

- Quality Control: Automated temperature monitoring, pressure control, in-line flexural testing

- Expected Service Life: 30+ years in industrial environments (per ScienceDirect)

Advantages of Molded Grating Machine Technology

- Integrated One-Piece Construction: Superior load & impact resistance compared to mechanically assembled types.

- Corrosion & Chemical Resistance: Outperforms steel/aluminum gratings especially in H2SO4, NaCl, Oil & Chlorine-rich atmospheres.

- Fire Retardant Formulation: Optional fire rating to ASTM E-84 Class 1.

- Non-Conductive Safety: Ideal for power stations, battery rooms, and utility vaults.

- Lightweight & Modular: Easy to install, reduces dead loads; can be fabricated onsite by hand tools.

- Customization: Modular molds for mesh pattern, panel size, thickness, and surface type.

Technical Comparison: FRP Molded Grating Machine vs. Pultrusion/Metal Grating

| FRP Molded Grating Machine | FRP Pultruded | Galvanized Steel | Aluminum Grating | |

|---|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Poor | Moderate |

| Mechanics (Flexural Modulus) | 7.2 GPa | 9.0 GPa | 210 GPa | 69 GPa |

| Service Life (in years) | 30+ | 20-25 | 8-15 | 12-20 |

| Non-Conductivity | Yes | No | No | No |

| Fire Rating | ASTM E-84, Class 1 | Class 1 | None | None |

| Typical Weight (kg/m²) | ~12 | ~8 | 35 | 18 |

| Installation Ease | Easy, modular | Easy | Labor-intensive | Medium |

Custom FRP Grating Machine Solutions & Modular Upgrades

According to CompositesWorld, custom-configured frp grating machine setups with integrated IoT sensors can reduce downtime by up to 18%. OEMs like YULONG Machinery offer full-cycle customization—helping you select mesh size, anti-slip surfaces, color pigments (per RAL), and automated demolding systems.

- Mesh Options: 25×25 / 38×38 / 50×50 mm; thickness 20–70 mm

- Color Customization: Green, grey, yellow, black, red (UV-resistant pigment)

- Textured Surface: Concave/gritted/smooth/grit-embedded

- Finish: Food-grade / Conductive / Ultra-fire-retardant

- Control Upgrades: IoT PLC, RFID tracking, energy-saving insulation

- Delivery: 15-35 days ex-works; CE and ISO-certified

Typical Applications & Case Studies for FRP Grating Machine Products

Petrochemical Platforms (Qatar)

The largest integrated refinery in the Middle East adopted a frp molded grating machine for walkways and chemical processing decks. Compared to galvanized steel:

- Corrosion-related maintenance cost fell by 72% in five years.

- Load rating exceeded ANSI A10.11 minimum by 37%.

- Surface anti-skid grade: R13 (DIN 51130).

Waste Water Treatment Plant (USA)

- Installed 8000㎡ GRP molded gratings via dedicated machine line

- Electrical insulation rating: > 25 kV for operator safety

- Operates in NaOH & Cl-rich conditions—zero delamination for 8 years

- Typical module replacement cycle: >30 years

Mining & Power Industry (Chile, Germany, China)

- Platform grating with resin upgrade for fire safety (ASTM E-84 Class 1)

- Modular joints tested per ISO 604, passed > 1,800,000 load cycles

- Annual plant-based cost saving: USD 165,000 in maintenance

Authoritativeness, Certifications & Long-Term Support

- Years in Service: Over 15 years manufacturing FRP equipment globally, with references in 20+ countries

- Certifications: ISO 9001, CE, ANSI, FDA, SGS available for different applications

- Partners: PetroChina, BASF, Veolia, CNOOC

- References: Some clients report full payback ROI under 20 months (View references)

- After-sales Support: 24/7 tech consult, on-site install, remote config, warranty up to 36 months

Frequently Asked Questions: FRP Grating Machine Technical Insights

A: Most frp grating machines use E-glass fibers (or occasionally S-glass for specialty strength) and a resin base of isophthalic/vinyl ester or phenolic for high corrosion and fire resistance.

A: Standard panel sizes are 1220×3660mm, up to 1800×6000mm. Thickness ranges from 20mm to 70mm; custom sizes are possible as per specific frp molded grating machine configuration.

A: Panels and equipment can be certified to ISO 9001, CE, ANSI, SGS, and fire tested to ASTM E-84/ISO 14122-2. Each project can be tailored for regulatory compliance.

A: Automated PLC systems control pressure/temperature. Each batch undergoes flexural, compressive, and impact testing, with traceability conducted by batch and RFID-encoded mold tags.

A: FRP gratings are mounted via SS clamps or bolted direct to frames; can also be suspended on custom hangers. Compliance with OSHA/ANSI installation spacing requirements is maintained.

A: Typical cycle time for a 40mm panel is 32–40min. Standard equipment can ship in 3–5 weeks, with custom mold projects taking 30–45 days.

A: All major systems are covered for 18-36 months, with spares and technical support available worldwide. Remote troubleshooting, live video support, and documentation keep downtime low.

Delivery, Warranty & Technical Service

- Delivery: Standard lines ready in 15–35 days after order confirmation

- Deployment: Turnkey on-site setup (& operator training) available on request

- Warranty: 18–36 months, extended warranty available

- Support: 24/7 phone, e-mail, and video assistance. All documentation in English.

- Maintenance: Service contracts for preventive maintenance and spare parts

- Samples: Free finished grating samples can be provided for qualification

Conclusion & Industry Resources

The demand for advanced frp grating machine technology—prioritizing anti-corrosion performance and modular production—continues to increase as safety, life-cycle costs, and regulatory compliance drive project selection. Customization, robust certifications, and proven casework are crucial for successful project outcomes. Refer to the following resources for up-to-date discussion and technical references:

- CompositesWorld: FRP Grating Market Insights

- ScienceDirect: Fiber Reinforced Plastic Properties

- Eng-Tips Forums: Grating Systems