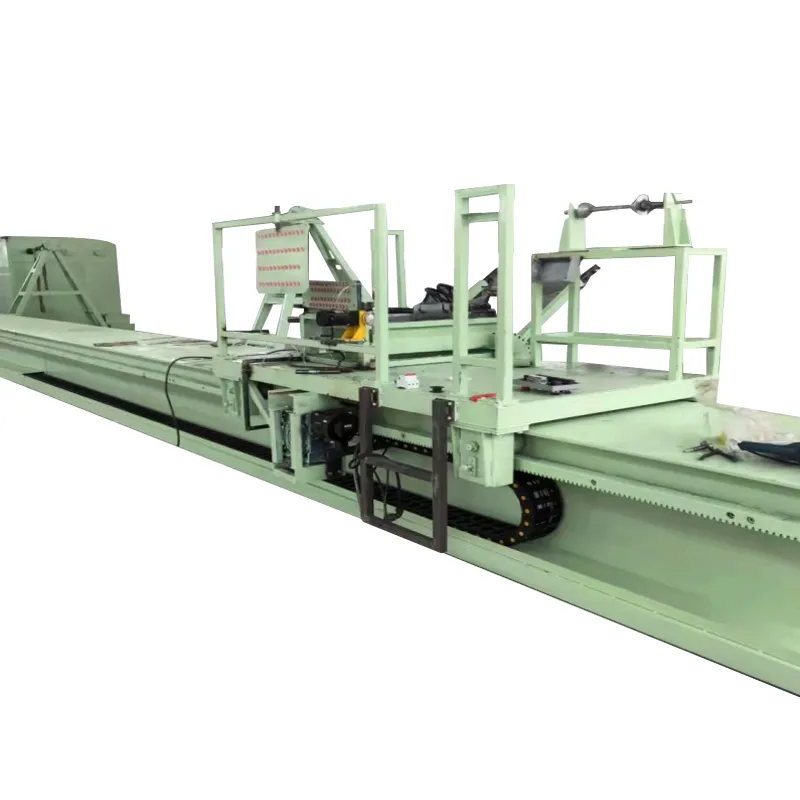

High-Performance FRP Tank Winding Machine: Precision & Efficiency

Advancing Industrial Infrastructure: The Evolution of FRP Tank Winding Technology

The demand for durable, corrosion-resistant, and lightweight storage solutions has propelled the Fiberglass Reinforced Plastic (FRP) industry to the forefront of modern engineering. At the heart of this advancement lies the sophisticated frp tank winding machine, a pivotal technology enabling the precise and efficient manufacturing of high-performance FRP tanks. These tanks are critical components across diverse sectors, safeguarding crucial liquids and gases from environmental degradation and ensuring operational longevity. This comprehensive overview delves into the industry trends, technical intricacies, application versatility, and the strategic advantages offered by state-of-the-art FRP tank winding technology, providing insights for B2B decision-makers and technical professionals seeking optimal composite solutions.

The global market for FRP composites continues to expand, driven by increasing infrastructure development, stringent environmental regulations, and the compelling need for materials that outperform traditional steel and concrete in corrosive environments. Fiberglass tanks, manufactured by advanced fiberglass tank winding machine systems, offer unparalleled chemical resistance, excellent strength-to-weight ratios, and significantly lower maintenance costs over their lifecycle. This makes them an ideal choice for sectors ranging from chemical processing to municipal water treatment. Understanding the core technologies and their impact is vital for leveraging these benefits effectively.

Decoding the Process: FRP Tank Winding Machine Manufacturing Workflow

The creation of a high-integrity FRP tank involves a sophisticated and precisely controlled manufacturing workflow, with the frp tank winding machine at its core. This process, known as filament winding, is an automated composite fabrication technique that lays continuous strands of fiber impregnated with resin onto a rotating mandrel. The selection of materials, meticulous manufacturing processes, and rigorous testing standards are paramount to ensure the final product meets the demanding requirements of industrial applications.

Material Selection: The Foundation of Durability

- Fibers: Primarily E-glass or corrosion-resistant ECR-glass rovings are used due to their high tensile strength and cost-effectiveness. Carbon or aramid fibers may be incorporated for specialized applications requiring extreme stiffness or impact resistance.

- Resins: The choice of resin dictates the tank's chemical resistance and temperature capabilities. Common options include:

- Isophthalic Polyester Resins: Good general-purpose corrosion resistance, suitable for water and many dilute chemicals.

- Vinyl Ester Resins: Superior chemical resistance, especially against strong acids, bases, and solvents, vital for chemical processing tanks.

- Bisphenol-A Fumarate Resins: Enhanced temperature and chemical resistance.

- Liners: For applications demanding absolute containment and extreme corrosion resistance, an inner thermoplastic liner (e.g., PVC, CPVC, PP, PVDF) may be used, creating a dual-laminate structure.

The Automated Manufacturing Process: Precision by Design

- Mandrel Preparation: A precisely manufactured, collapsible or sacrificial mandrel (mold) forms the inner shape of the tank. Its surface is prepared with a release agent to allow for easy removal after curing.

- Inner Liner Application (if applicable): For dual-laminate tanks, the thermoplastic liner is first placed onto the mandrel and possibly welded to form a seamless inner shell.

- Corrosion Barrier/Liner Layer Winding: A resin-rich layer, often reinforced with C-glass veil or synthetic surfacing veil, is applied to the mandrel or liner. This forms the primary corrosion barrier, typically 2.5-5mm thick, designed to withstand the contained chemical. This initial layer ensures maximum chemical resistance and minimal permeability.

- Structural Layer Winding: This is where the grp winding machine excels. Continuous rovings of fiberglass are pulled through a resin bath, impregnating them thoroughly. The resin-soaked fibers are then precisely wound onto the rotating mandrel at specific winding angles (e.g., helical, circumferential, or a combination) determined by the tank's structural requirements (pressure, vacuum, bending loads). Multi-axis control systems on advanced machines allow for complex winding patterns, optimizing the strength distribution. This automated process ensures consistent fiber-to-resin ratio and void-free laminate.

- Outer Layer/Top Coat Application: An external layer, often reinforced with chopped strand mat and pigmented resin, is applied for UV protection, abrasion resistance, and aesthetic finish.

- Curing: The wound tank on the mandrel undergoes a controlled curing process. This can be at ambient temperature or elevated temperatures in an oven, depending on the resin system. Curing transforms the liquid resin into a rigid thermoset plastic, locking the fibers into place and achieving full mechanical properties.

- Demolding and Finishing: Once cured, the mandrel is collapsed and removed. The tank is then inspected, trimmed, and fitted with nozzles, manways, and other accessories. This may involve precision CNC machining for flange faces or connection points, ensuring compliance with industry standards.

The entire process, from mandrel preparation to finishing, is carefully controlled to ensure the highest quality. The use of advanced CNC-controlled frp tank filament winding machine allows for unparalleled precision in fiber placement, leading to consistent and high-strength tank structures.

Quality Assurance and Industry Standards

Ensuring the integrity and reliability of FRP tanks is paramount. Manufacturers utilizing fiberglass tank winding machine technologies adhere to stringent international standards and rigorous internal quality control measures. Key standards include:

- ASTM D3299: Standard Specification for Filament-Wound Glass-Fiber-Reinforced Thermoset Resin Chemical-Resistant Tanks.

- ASME RTP-1: Reinforced Thermoset Plastic Corrosion-Resistant Equipment. This standard covers design, fabrication, inspection, and testing.

- ISO 9001: Quality management system certification, ensuring consistent product quality and continuous improvement in the manufacturing process.

- EN 13121: GRP tanks and vessels for use above ground.

- Hydrostatic Testing: Each tank undergoes a hydrostatic pressure test to verify structural integrity and leak-tightness.

- NDE (Non-Destructive Examination): Ultrasonic testing, visual inspection, and acoustic emission testing are often employed to detect any internal flaws or delaminations.

These standards, coupled with advanced manufacturing techniques enabled by the frp tank winding machine, ensure a service life often exceeding 20-30 years, significantly outperforming traditional materials in corrosive environments.

Key Technical Parameters and Specifications of FRP Tank Winding Machines

The performance and versatility of a frp tank winding machine are defined by its technical specifications. These parameters directly influence the quality, size, and type of tanks that can be produced. When evaluating a machine, industrial buyers focus on factors that dictate throughput, precision, and operational flexibility.

| Parameter | Description | Typical Range / Value |

|---|---|---|

| Winding Axes | Number of controlled axes for precise fiber placement. More axes allow for complex geometries and optimal strength. | 3-axis (mandrel rotation, carriage traverse, cross-feed) to 6-axis (additional head rotation, fiber payout angle control). |

| Mandrel Diameter Range | Minimum and maximum diameter of tanks that can be wound. | DN500mm to DN15000mm (or 0.5m to 15m). |

| Mandrel Length Capacity | Maximum length of tanks that can be manufactured. | 2m to 25m (or custom longer lengths). |

| Winding Speed | Maximum linear speed of fiber payout or rotational speed of mandrel. Directly impacts production efficiency. | 5-80 m/min (fiber speed); 1-10 rpm (mandrel speed). |

| Winding Angle Range | The range of angles at which fibers can be laid relative to the mandrel axis. Crucial for structural design. | Typically 15° to 90° (helical to circumferential). |

| Number of Spindles/Creels | How many rovings (fiber bundles) can be wound simultaneously. More rovings increase winding speed. | 10 to 60 (or more for specialized machines). |

| Control System | Type of control system for precision and automation. | PLC (Programmable Logic Controller) with HMI (Human Machine Interface); Industrial PC-based with specialized winding software. |

| Power Consumption | Total electrical power required for operation. | 15 kW to 100 kW+, depending on size and features. |

| Machine Footprint | Physical dimensions of the machine, crucial for facility planning. | Length equivalent to max tank length + 5-10m; Width 3-8m; Height 2.5-4m. |

| Resin Bath System | Features of the resin impregnation system. | Automatic resin mixing and temperature control, precise resin content management, self-cleaning options. |

These parameters collectively determine the efficiency, precision, and range of products a grp winding machine can produce. Advanced machines often feature closed-loop control systems, real-time monitoring, and remote diagnostics, ensuring consistent quality and minimizing downtime.

Unleashing Potential: Application Scenarios of FRP Tanks

Tanks produced by a reliable frp tank winding machine are indispensable across a multitude of industrial sectors, providing robust and long-lasting storage for a wide array of substances. Their inherent corrosion resistance and design flexibility make them superior to traditional materials in many challenging environments.

- Chemical Processing Industry (CPI): This is a primary sector for FRP tanks. They are used for storing aggressive chemicals like acids (hydrochloric, sulfuric, nitric), alkalis (sodium hydroxide), solvents, and various chemical intermediates. The ability to resist a broad spectrum of corrosive media at varying temperatures is a key advantage, preventing leaks, contamination, and costly downtime. FRP tanks produced by advanced frp tank filament winding machine systems excel in environments where steel or even stainless steel would quickly corrode, ensuring long-term containment integrity.

- Oil & Gas Sector: From upstream production to midstream transportation and downstream refining, FRP tanks are used for storing produced water, crude oil, fuels, and chemicals used in drilling or processing. Their lightweight nature facilitates transport and installation in remote locations, and their non-conductive properties reduce risks associated with static electricity build-up.

- Water and Wastewater Treatment: Critical for municipal and industrial applications, FRP tanks store potable water, treated wastewater, brine, and various treatment chemicals (e.g., chlorine, ferric chloride, alum). Their non-corrosive nature ensures water purity and prevents deterioration of infrastructure, offering significant advantages over concrete or steel tanks which are susceptible to corrosion from aggressive chemicals or microbial induced corrosion.

- Power Generation: Used in cooling water systems, demineralized water storage, and flue gas desulfurization (FGD) systems for storing slurries and chemicals. Their ability to withstand high temperatures and corrosive flue gas components contributes to the efficiency and longevity of power plants.

- Mining and Metallurgy: For storing process water, reagents, and slurries involved in mineral extraction and processing. The abrasive and corrosive nature of mining environments makes FRP an ideal material choice.

- Food & Beverage Industry: While less common for direct food contact without specific liners, they are used for process water, cleaning solutions, and non-food grade chemicals.

- Pulp and Paper Industry: Storage of various bleaching chemicals, black liquor, and process water, where corrosion is a constant challenge.

- Agriculture: For bulk storage of fertilizers, pesticides, and irrigation water, offering durability and resistance to agricultural chemicals.

In these typical application scenarios, FRP tanks consistently demonstrate advantages such as energy efficiency (due to lower heat conductivity compared to steel), superior corrosion resistance, minimal maintenance requirements, and extended operational lifespans, contributing to significant lifecycle cost savings. The precision of the fiberglass tank winding machine ensures that each tank meets the specific chemical and mechanical demands of its intended application.

Technical Advantages of Advanced FRP Tank Winding Technology

Modern frp tank winding machine systems offer a compelling suite of technical advantages that directly translate into superior product quality, enhanced manufacturing efficiency, and significant operational benefits for end-users.

- Precise Fiber Orientation and Layup: Advanced multi-axis CNC control systems (e.g., 4-axis, 6-axis) allow for highly precise control over winding angles and fiber placement. This ensures that fibers are oriented optimally to withstand specific loads (hoop stress for internal pressure, axial stress for bending), leading to maximized strength-to-weight ratios and minimized material usage. This precision is difficult to achieve with hand layup methods.

- Consistent Laminate Quality: The automated and controlled resin impregnation and winding process minimizes human error and variability. This results in a highly consistent fiber-to-resin ratio, uniform wall thickness, and reduced void content throughout the tank laminate, directly contributing to superior mechanical properties and long-term durability. Quality control on a grp winding machine is inherently more robust.

- High Strength-to-Weight Ratio: By strategically placing continuous high-strength glass fibers, filament wound tanks achieve exceptional strength while remaining significantly lighter than metallic alternatives. This reduces transportation costs, simplifies installation, and minimizes foundation requirements.

- Superior Corrosion Resistance: The choice of specific resins (e.g., vinyl ester, isophthalic) and the ability to create a thick, resin-rich inner corrosion barrier during the winding process provide unparalleled resistance to a vast range of corrosive chemicals, acids, and alkalis. This is a critical advantage over traditional steel tanks that require expensive linings or frequent replacement in corrosive environments.

- Design Flexibility and Customization: Modern frp tank filament winding machine systems can produce tanks of various sizes, shapes (vertical, horizontal), and configurations (flat bottom, dished bottom, cone bottom). The ability to integrate specific nozzle placements, manways, and internal structures during the winding process enhances design adaptability to unique project requirements.

- Reduced Manufacturing Time and Labor Costs: Automation significantly speeds up the production process compared to labor-intensive hand layup. This leads to higher throughput, lower manufacturing costs per unit, and more competitive pricing for the end product.

- Improved Safety and Environmental Impact: The durability and corrosion resistance of FRP tanks minimize the risk of leaks and spills, enhancing operational safety and reducing environmental contamination risks. Furthermore, the manufacturing process itself can be optimized for reduced material waste.

- Lower Lifecycle Costs: While the initial investment in an FRP tank might sometimes be higher than a basic steel tank, the long service life (20-30+ years), minimal maintenance requirements, and resistance to degradation in harsh environments lead to significantly lower total lifecycle costs.

Navigating the Market: Manufacturer Comparison & Selection Criteria

Choosing the right frp tank winding machine supplier is a strategic decision that impacts production quality, efficiency, and long-term operational success. While specific vendor names are beyond the scope of this generic article, we can outline key comparison criteria and the types of solutions available in the market. Manufacturers differentiate themselves based on technological sophistication, after-sales support, and specialization.

Types of FRP Tank Winding Systems and Their Characteristics

| Feature | Entry-Level Systems (e.g., 2-Axis) | Mid-Range Automation (e.g., 3-Axis) | High-Precision Industrial Systems (e.g., 4-6 Axis) |

|---|---|---|---|

| Control System | Basic PLC, manual parameter input. | Advanced PLC with HMI, semi-automatic programming. | Industrial PC with advanced winding software (e.g., CAD/CAM integration), real-time monitoring. |

| Winding Flexibility | Limited to simple cylindrical shapes, fixed winding angles. | Can handle simple conical sections, basic helical and circumferential patterns. | Complex geometries (domes, varying diameters), variable winding angles, geodesic path generation for optimal strength. |

| Tank Size Range | Small to medium (e.g., 0.5m - 5m diameter). | Medium to large (e.g., 1m - 10m diameter). | Very large (e.g., 2m - 15m+ diameter) and long. |

| Production Speed | Moderate. | Good, suitable for consistent production volumes. | Very high, ideal for mass production of large tanks or complex parts. |

| Precision & Repeatability | Acceptable for non-critical applications. | High, meeting most industrial standards. | Exceptional, critical for high-pressure or extreme chemical service. |

| Cost | Lower initial investment. | Medium investment, good ROI for varied production. | Higher investment, justified by quality, speed, and versatility. |

Key Factors in Manufacturer Selection:

- Technological Capability: Does the manufacturer offer the axis configuration and control sophistication required for your specific tank designs and production volume? Look for expertise in CNC programming and composite winding software.

- Experience and Track Record: How many years has the company been in the fiberglass tank winding machine business? Can they provide references or showcase successful installations globally?

- Customization & Integration: Can they tailor the machine to your specific facility constraints or integrate it with existing production lines (e.g., resin mixing, curing ovens, finishing stations)?

- After-Sales Support: What kind of installation, training, maintenance, and spare parts support do they offer? Global reach for support is crucial.

- Compliance and Certification: Do their machines meet international safety standards (CE, UL)? Are their internal quality management systems ISO certified?

- Innovation & R&D: Is the manufacturer actively investing in R&D to improve winding speed, material efficiency, and automation? This indicates a commitment to long-term partnership.

By carefully evaluating these aspects, businesses can select a grp winding machine partner that aligns with their production goals and ensures high-quality FRP tank output.

Tailored Excellence: Customization Solutions for FRP Tank Winding Machines

Recognizing that no two manufacturing operations are identical, leading providers of frp tank winding machine solutions offer extensive customization options. This ensures that the equipment perfectly integrates with a client's existing infrastructure, production requirements, and specific product portfolio. Customization can range from minor adjustments to complete bespoke system designs.

- Mandrel Support and Handling Systems: Custom designs for handling various mandrel types (collapsible, fixed, expandable) and sizes. This includes specialized chucks, tailstocks, and overhead crane integration for heavy mandrels. For example, a client requiring tanks up to 15m in diameter would need a significantly different support system than one producing 2m diameter tanks.

- Resin Delivery & Impregnation Systems: Tailored resin baths to accommodate different resin viscosities, curing speeds, and types (e.g., dual resin systems for liner and structural layers). Options include automated temperature control, degassing units, and precise resin metering systems for optimal fiber wet-out and minimal waste.

- Multi-Axis Configuration: While standard machines may be 3-axis, customization allows for adding more axes (e.g., 4-axis for independent cross-feed, 6-axis for complex head articulation) to enable more intricate winding patterns, handle varying tank diameters seamlessly, or integrate specialized add-ons.

- Fiber Delivery & Tension Control: Customized creel systems to hold various numbers of fiber spools (rovings) and precise tensioning mechanisms (e.g., pneumatic, electronic) to ensure uniform fiber placement, critical for tank strength. This can involve high-capacity creels for large-scale production or specialized creels for hybrid fiber winding.

- Software Integration & Automation: Development of custom winding programs for unique tank geometries or material combinations. Integration with existing factory automation systems (SCADA, MES) for centralized control, data logging, and production monitoring. This can include features like predictive maintenance alerts or automated production scheduling.

- Safety Features: Tailored safety enclosures, light curtains, emergency stop protocols, and interlocks to meet specific regional safety regulations (e.g., OSHA, CE) and enhance operator protection.

- Environmental Controls: Integration of fume extraction systems, ventilation solutions, and waste management features to ensure compliance with environmental regulations and maintain a safe working environment.

- Post-Winding Handling: Custom solutions for automated transfer of wound tanks to curing ovens, or integration with trimming and finishing stations, optimizing the entire production line.

A prime example of customization is a client needing to produce very large diameter (e.g., 12m) tanks for municipal water storage, combined with smaller, chemically resistant tanks (e.g., 2m diameter) for industrial applications. A single, highly customizable fiberglass tank winding machine with adaptable mandrel supports and programmable winding patterns can accommodate both requirements efficiently, providing a versatile solution that maximizes ROI. This tailored approach ensures optimal utilization of resources and superior product output, addressing unique challenges in composite manufacturing.

Real-World Impact: Illustrative Application Cases of FRP Tanks

The efficacy and reliability of FRP tanks manufactured by a sophisticated frp tank winding machine are best demonstrated through their successful deployment in challenging industrial environments. These case studies highlight the tangible benefits and problem-solving capabilities of FRP composite technology.

- Case Study 1: Chemical Plant Acid Storage Upgrade

A major chemical manufacturing facility in the Gulf Coast region faced persistent corrosion issues with their existing steel storage tanks used for concentrated hydrochloric acid (HCl) and sodium hypochlorite. Frequent repairs and premature replacements led to significant operational disruptions and high maintenance costs. After extensive material compatibility studies, they opted for custom-designed dual-laminate FRP tanks, fabricated using a high-precision grp winding machine. These tanks featured an inner PVDF thermoplastic liner bonded to a vinyl ester FRP composite shell. The project involved the replacement of twelve 50,000-gallon tanks. Post-installation, the tanks have shown zero signs of corrosion or leakage over five years, significantly reducing maintenance expenditure by an estimated 70% annually and eliminating unscheduled downtime, demonstrating the superior performance and longevity of properly manufactured FRP solutions.

- Case Study 2: Municipal Wastewater Treatment Plant Expansion

A growing metropolitan area required an expansion of its wastewater treatment facilities, including new primary clarifiers and chemical dosing tanks. Conventional concrete tanks were considered, but concerns about long-term microbial induced corrosion (MIC) and the need for faster installation led them to choose large-diameter (10m) FRP tanks for various treatment stages and chemical storage (e.g., ferric chloride for phosphorus removal). The tanks were produced efficiently using a large-scale fiberglass tank winding machine, enabling rapid on-site assembly. The lightweight nature of FRP allowed for less robust foundations compared to concrete, further reducing project costs. The client reported a 25% faster overall construction time for the tank components and anticipates a service life of over 30 years without major structural maintenance, contributing to sustainable urban infrastructure.

- Case Study 3: Remote Oil & Gas Field Water Storage

In a remote and environmentally sensitive oil field, the need arose for temporary and then permanent storage of produced water. Traditional steel tanks were logistically challenging to transport and install due to their weight and the difficult terrain. The solution involved using modular FRP tanks manufactured by a portable frp tank filament winding machine setup. These tanks were designed for easy assembly on-site. Their corrosion resistance was critical given the saline nature of produced water. The reduced weight meant smaller, less invasive lifting equipment was needed, minimizing environmental impact. The rapid deployment capabilities and inherent durability in harsh, remote conditions proved FRP tanks to be the most viable and cost-effective solution, enabling quicker operational setup and reduced logistical complexities.

These cases underscore how precision engineering, facilitated by advanced frp tank winding machine technology, provides robust, economically viable, and environmentally sound solutions for critical industrial storage needs. Client feedback consistently highlights the long-term reliability and significant operational savings achieved.

Ensuring Trust and Reliability: Your Partner in FRP Solutions

Beyond the technical specifications and application benefits, the trustworthiness of a frp tank winding machine supplier is paramount. This encompasses transparent operations, strong customer support, and robust quality assurances. As a leading manufacturer of FRP Tank Machines, we prioritize building long-term relationships based on reliability and performance.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a custom frp tank winding machine?

A: The delivery cycle for a custom machine typically ranges from 3 to 6 months, depending on the complexity of the design and the level of customization. Standard models may have shorter lead times. We provide a detailed project timeline upon order confirmation. - Q: What kind of training is provided for operating the machine?

A: We offer comprehensive training programs, both on-site at your facility and at our manufacturing plant. This covers machine operation, maintenance, programming for various tank designs, and troubleshooting, ensuring your team is fully proficient. - Q: What are the power and space requirements for installation?

A: Power requirements vary by machine size, generally ranging from 15 kW to 100 kW+. Space requirements depend on the maximum tank length you intend to produce. Our technical team will provide detailed layout drawings and utility specifications for your site planning. - Q: Can the machine produce tanks of varying sizes and shapes?

A: Yes, our advanced fiberglass tank winding machine systems are designed for high versatility. With programmable controls and adaptable tooling, they can produce cylindrical, conical, and even spherical sections for vertical and horizontal tanks of different diameters and lengths.

Delivery Cycle & Logistics

We manage a streamlined supply chain and logistics process to ensure timely delivery of your grp winding machine. From ex-factory inspection to crating, customs clearance, and global shipping (sea freight, air freight, or multimodal options), every step is meticulously coordinated. Our team provides regular updates on shipment status and handles all necessary documentation to ensure a smooth import process.

Quality Assurance and Warranty Commitment

Our commitment to quality is upheld through ISO 9001 certified manufacturing processes. Each frp tank filament winding machine undergoes rigorous pre-delivery testing and quality checks to meet the highest performance and safety standards. We provide a comprehensive warranty on all major components, typically covering 12-24 months from the date of commissioning, against manufacturing defects. Detailed warranty terms and conditions are provided with every quote.

Dedicated Customer Support

Our relationship doesn't end after delivery. We offer robust after-sales support, including:

- Technical Assistance: Remote and on-site technical support for troubleshooting, optimization, and routine maintenance.

- Spare Parts Supply: Readily available genuine spare parts to minimize downtime.

- Software Updates: Continuous software enhancements and updates to improve machine performance and introduce new functionalities.

- Consulting Services: Expert advice on composite material selection, winding pattern design, and production optimization.

Our goal is to be a long-term partner in your success, providing reliable machinery and unparalleled support for your FRP tank manufacturing needs.

Conclusion

The frp tank winding machine represents a pinnacle in composite manufacturing technology, offering unmatched precision, efficiency, and versatility for producing high-performance Fiberglass Reinforced Plastic tanks. These advanced machines are not merely tools but critical assets that empower industries to overcome the challenges of corrosion, weight, and maintenance inherent in traditional materials. By leveraging cutting-edge winding techniques, sophisticated control systems, and adherence to rigorous international standards, manufacturers can deliver FRP tanks that excel in durability, chemical resistance, and structural integrity across diverse applications, from petrochemical and mining to water treatment and power generation.

Investing in a high-quality fiberglass tank winding machine is an investment in long-term operational efficiency, reduced lifecycle costs, and enhanced safety. The ability to customize solutions, coupled with comprehensive after-sales support and a commitment to quality assurance, ensures that businesses are not just acquiring equipment, but forging a strategic partnership dedicated to advancing their manufacturing capabilities and market leadership in the composite industry.

References

- ASTM International. (2022). ASTM D3299/D3299M-22, Standard Specification for Filament-Wound Glass-Fiber-Reinforced Thermoset Resin Corrosion-Resistant Tanks. ASTM International, West Conshohocken, PA.

- ASME. (2023). ASME RTP-1, Reinforced Thermoset Plastic Corrosion-Resistant Equipment. The American Society of Mechanical Engineers, New York, NY.

- Gay, D., Strong, A.B., & Wulff, R. (2014). Composite Materials, Third Edition: Design and Applications. CRC Press, Boca Raton, FL.

- Mallick, P.K. (2007). Fiber-Reinforced Composites: Materials, Manufacturing, and Design, Third Edition. CRC Press, Boca Raton, FL.

- Middendorf, B., & Dransfeld, C. (2016). Filament Winding: Process, Technology, and Applications. Carl Hanser Verlag GmbH & Co. KG, Munich.

- ISO. (2015). ISO 9001:2015, Quality management systems – Requirements. International Organization for Standardization.