High-Precision FRP Tank Winding Machine | GRP & Fiberglass

In the landscape of modern industrial manufacturing, the demand for high-performance, corrosion-resistant, and lightweight storage solutions is at an all-time high. This has catapulted Fiber Reinforced Polymer (FRP) tanks to the forefront of the industry. At the heart of this revolution lies a pivotal piece of technology: the frp tank winding machine. This comprehensive guide delves deep into the world of the frp tank filament winding machine, exploring industry trends, technical specifications, manufacturing processes, and key advantages that make it an indispensable asset for sectors ranging from petrochemicals to water treatment.

1. Market Dynamics & Industry Trends: The Rise of Composite Tanks

The global FRP tank market is on a significant upward trajectory, projected to grow at a CAGR of over 6.5% in the coming years. This growth is driven by the intrinsic limitations of traditional materials like steel and concrete, which are susceptible to corrosion, heavy, and often require extensive maintenance. The fiberglass tank winding machine is the enabling technology behind this shift, allowing for the automated, precise, and cost-effective production of GRP (Glass Reinforced Plastic) tanks that offer unparalleled performance. As environmental regulations tighten and operational efficiency becomes paramount, the adoption of FRP tanks fabricated by advanced grp winding machine systems is no longer a choice but a strategic necessity for forward-thinking industries.

2. Technical Specifications: Inside the Frp Tank Machine

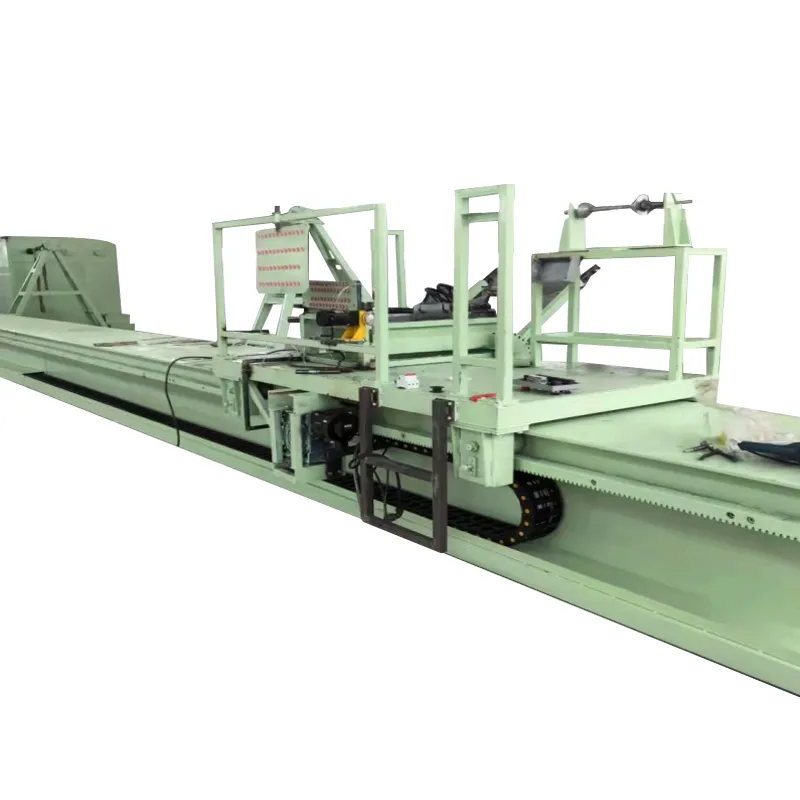

Understanding the technical parameters of an frp tank winding machine is crucial for evaluating its capabilities. These machines are complex systems where precision engineering meets advanced material science. Below is a detailed specification table for a typical high-performance Frp Tank Machine, showcasing the key metrics that define its production capacity and the quality of the final product.

| Parameter | Specification | Description & Impact on Performance |

|---|---|---|

| Tank Diameter Range | DN600 - DN4000 mm | Defines the size versatility of the machine. A wider range allows for production of tanks for diverse applications, from small chemical dosing to large-scale water storage. |

| Maximum Tank Length | Up to 12,000 mm | Determines the maximum volume of a single tank unit. Longer lengths are crucial for industries requiring high storage capacity. |

| Winding Angle (θ) | 45° - 90° (Helical & Hoop) | A critical parameter controlling the tank's mechanical properties. Hoop winding (~90°) provides circumferential strength, while helical winding (e.g., 55°) provides both hoop and axial strength. |

| Winding Speed | 0 - 120 m/min | Directly impacts production efficiency. Higher speeds, combined with precise control, lead to faster cycle times without compromising quality. |

| Control System | PLC with CNC Controller | Ensures high precision, repeatability, and complex winding patterns. Allows for pre-programmed recipes for different tank designs, compliant with standards like ISO 14692. |

| Resin System Compatibility | Polyester, Vinyl Ester, Epoxy | The ability to handle various resin systems is vital for producing tanks for specific chemical environments (e.g., Vinyl Ester for aggressive acids). |

| Fiber Types | E-Glass, ECR-Glass, Carbon Fiber | Flexibility in fiber reinforcement allows for tailoring the tank's strength, chemical resistance, and cost. ECR-glass offers superior corrosion resistance. |

| Machine Power | ~30 kW | Indicates the energy consumption and the power of the drive systems, which must be robust enough for continuous, heavy-duty operation. |

| Estimated Lifespan | > 20 Years | Reflects the build quality and durability of the machine's components, which are often CNC machined from high-grade steel and undergo rigorous quality checks. |

3. The Manufacturing Process: From Fiber to Finished Tank

The creation of a high-integrity FRP tank is a multi-stage process, orchestrated with precision by the frp tank filament winding machine. The entire workflow is designed to meet stringent international standards like ANSI/AWWA D120 and ASTM D3299, ensuring reliability and safety.

Mandrel Preparation & Liner Fabrication

The process begins with a collapsible or extractable steel mandrel, which acts as the mold for the tank. A chemically resistant, seamless inner liner (often made of thermoplastic or a resin-rich FRP layer) is fabricated on this mandrel. This liner is the primary barrier against corrosion.

Filament Winding

This is the core stage. The CNC-controlled frp tank winding machine rotates the mandrel while a carriage moves longitudinally, laying down continuous strands of fiber (rovings) impregnated with a precise amount of catalyzed resin. The machine alternates between helical and hoop winding patterns to build up the structural wall layer by layer, achieving the designed strength and thickness.

Curing Process

Once winding is complete, the tank is cured. This is a critical chemical reaction (polymerization) where the resin hardens, creating a solid composite matrix. Curing is often accelerated using controlled heating systems (infrared or hot air) to ensure complete cross-linking for optimal mechanical and chemical properties.

Demolding and Extraction

After curing and cooling, the mandrel is collapsed or extracted from the newly formed tank shell. This process must be done carefully to avoid damaging the tank's interior surface.

Finishing and Quality Control

The tank ends (domes or flat ends) are attached, and nozzles or manways are installed. The finished tank undergoes rigorous quality testing, including hydrostatic pressure tests, dimensional checks, and Barcol hardness tests to verify compliance with design specifications and industry standards like ISO 9001.

4. Key Technological Advantages of Filament Wound FRP Tanks

The products created by a fiberglass tank winding machine offer a host of advantages over traditionally constructed tanks. These benefits stem directly from the materials used and the precision of the manufacturing process.

Superior Corrosion Resistance

Unlike steel, FRP does not rust or corrode. By selecting the appropriate resin system (e.g., vinyl ester for harsh chemicals, isophthalic polyester for water), tanks can be engineered to safely store a vast range of corrosive substances for decades, dramatically reducing maintenance costs and downtime.

High Strength-to-Weight Ratio

FRP composites are incredibly strong yet remarkably lightweight. An FRP tank can have the same strength as a steel tank but at a fraction of the weight. This translates to easier transportation, simpler installation (requiring less heavy machinery), and reduced structural support requirements.

Design & Fabrication Flexibility

The filament winding process allows for immense design freedom. The frp tank winding machine can create tanks of various shapes, sizes, and thicknesses, with winding angles optimized for specific pressure or load conditions. This allows for highly customized solutions tailored to precise application needs.

Exceptional Durability & Long Service Life

Properly designed and manufactured FRP tanks can have a service life exceeding 30-40 years, even in harsh environments. The composite structure is resistant to fatigue, impact, and UV degradation (with appropriate additives), ensuring a long-term, reliable investment.

5. Data-Driven Performance Insights

Visualizing data provides a clearer understanding of the market landscape and material advantages. The charts below illustrate the dominance of FRP in key areas.

FRP Tank Application Market Share

- Chemical & Petrochemical (40%)

- Water & Wastewater (30%)

- Pulp & Paper (20%)

- Other Industries (10%)

Comparative Material Tensile Strength

6. Choosing the Right Partner: Manufacturer & Machine Comparison

Selecting the right frp tank winding machine goes beyond just the technical specs; it involves choosing a reliable manufacturer who offers robust technology, customization, and comprehensive support. Our Frp Tank Machine stands out by delivering on all fronts.

| Feature | Our Frp Tank Machine | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Control System | Advanced CNC with proprietary optimization software | Standard PLC Control | Basic PLC, limited patterns |

| Customization | Fully customizable for diameter, length, resin systems, and automation level | Limited customization options | Standard models only |

| Component Quality | CNC-machined parts from forged steel, certified electronics (Siemens, Schneider) | Cast components, generic electronics | Standard grade materials |

| After-Sales Support | 24/7 technical support, on-site installation & training, 2-year warranty | Business hours support, 1-year warranty | Email support only |

| Industry Certification | ISO 9001, CE Certified | ISO 9001 | Not specified |

7. Tailored for Success: Customization and Application Solutions

No two industrial applications are identical. That's why the ability to customize the grp winding machine is a cornerstone of our offering. We collaborate closely with clients to engineer solutions that perfectly match their production needs.

Application Case Study: Petrochemical Plant in the Middle East

- Challenge: A client required storage tanks for highly corrosive hydrochloric acid (HCl) at elevated temperatures. Their existing steel tanks were failing within 3-5 years, causing costly downtime and safety hazards.

- Solution: We provided a customized frp tank winding machine configured to work with a premium Vinyl Ester resin system and ECR-glass fibers. The machine's software was programmed with a specific multi-layer winding pattern to maximize chemical and thermal resistance.

- Result: The client is now producing FRP tanks with an expected service life of over 25 years. They reported a 60% reduction in annual maintenance costs and have eliminated downtime related to tank corrosion. This success story showcases the tangible ROI of investing in a high-quality, customized machine.

8. Your Questions Answered: Professional FAQ

Hoop (or circumferential) winding involves wrapping fibers at nearly 90 degrees to the tank's axis. This provides strength against the outward pressure (hoop stress) from the stored liquid. Helical winding involves wrapping at a lower angle (e.g., 55 degrees), which provides both hoop strength and axial (longitudinal) strength. A high-performance frp tank winding machine combines both patterns in multiple layers to create a structurally optimized tank.

The choice of resin is critical and depends entirely on the chemical environment and temperature.

- Orthophthalic Polyester: General purpose, good for water and brine.

- Isophthalic Polyester: Better chemical and thermal resistance than Ortho.

- Vinyl Ester: Excellent resistance to a wide range of acids, alkalis, and solvents. The go-to choice for most aggressive chemical applications.

- Epoxy: Superior mechanical properties and thermal resistance, often used in high-pressure vessels and aerospace.

A CNC (Computer Numerical Control) system provides unparalleled precision and repeatability that is impossible to achieve manually. It controls every critical variable: winding speed, carriage movement, fiber tension, and resin-to-fiber ratio. This ensures that every tank produced is identical in quality and adheres exactly to the design specifications, guaranteeing consistent mechanical properties and eliminating weak spots.

Our machines are built for durability with high-quality components. Routine maintenance includes:

- Regular cleaning of the resin bath and impregnation system.

- Lubrication of moving parts like bearings and chains.

- Inspection of drive belts and fiber tensioning systems.

- Periodic calibration of the CNC controller.

The standard delivery cycle for our frp tank filament winding machine is typically 60-90 days, depending on the level of customization. Each machine comes with a comprehensive 2-year warranty covering all major components. We also offer extended service plans and have a dedicated customer support team available 24/7 for troubleshooting and assistance.

Yes. The machine can be configured to produce double-wall FRP tanks that meet stringent environmental standards for underground fuel storage, such as UL 1316. This involves specific winding patterns for added stiffness to withstand soil pressure and the integration of interstitial space for leak monitoring systems.

Our commitment to quality is validated by our ISO 9001:2015 certification, which governs our entire design, manufacturing, and testing process. Our machines are CE certified for the European market. We use components from globally recognized, authoritative brands like Siemens and Schneider Electric. Furthermore, our designs and the tanks they produce are engineered to comply with major international standards like ASTM, ANSI, and BS 4994, ensuring trust and reliability.

9. Our Commitment: Trustworthiness Through Service and Support

Investing in an frp tank winding machine is a significant decision. We build trust not just through superior technology, but through unwavering commitment to our clients' success. Our relationship extends far beyond the sale.

- In-depth Consultation: We begin with a thorough analysis of your needs to propose the most effective and economical solution.

- On-Site Installation & Training: Our expert engineers oversee the installation and provide comprehensive training to your operators on machine operation, maintenance, and safety protocols.

- Lifetime Technical Support: Our global support team is available around the clock to assist with any operational questions or challenges, ensuring minimal downtime.

- Spare Parts Availability: We maintain a ready stock of all critical spare parts for immediate dispatch, safeguarding your production continuity.

Further Reading & Authoritative References

To further enhance your understanding of composite materials and filament winding technology, we recommend exploring these authoritative sources:

1. Composites World Magazine: An excellent resource for industry news, technical articles, and market analysis on filament winding. Visit: CompositesWorld - Filament Winding Zone

2. Journal of Composite Materials: For in-depth academic research on the mechanical properties and performance of filament-wound structures. An exemplary article, "Analysis of filament-wound cylindrical shells under combined loading," highlights the complex engineering principles our machines are built upon. Find similar research on platforms like SAGE Journals.

This dedication to expertise, backed by experience and validated by authoritative standards, makes our Frp Tank Machine the trusted choice for leaders in the composite manufacturing industry.